Catalog excerpts

Operation Schematic – PED Version for Underground PED ® Loop anten na (Surf ace or U nderg round ) Hard Wired or Fiber Optic Link The LF version operates similarly except the signals are transmitted by the mine’s radio system rather than the PED ® Transmission System Windows PC running Pedcall software for entering messages PED® Modulator with Emergency Message Buttons Ultra Low Frequency signals transmitted through rock strata PED® ULF Transmission Headend Cost Benefits Underground Experience at mines using BlastPED has shown eliminating extensive cabling or signal tube runs can increase production time per shift can by an average of 45 minutes as clearing the mine of all people is simplied. • Reducing the number of misres by eliminating extensive cabling networks. • With no personnel underground during blasting, drill holes do not need to be grouted to prevent fumes can spread outside blast areas via these drill holes. • Shotrers are not required to prolong shifts to initiate blasts. Operation Schematic – ST Version for Surface Mines Demonstrated in over 100 installations since the rst installation in 1995. Compliance with appropriate blasting device standards. Based on this compliance, its security of operation, and the results of rigorous Risk Assessments, BlastPED has received approval or recognition for use by various mining authorities around the world, including Australia, Canada, United States, South Africa and Chile. The system security is based on the unique operating ® frequency and coding techniques of the PED system. Key ® features in relation to PED which contribute to the levels of security include: • Sophisticated encoding and decoding techniques in the ® PED signalling system which ensures absolute integrity of the signal. • Security is further increased by the requirement for two separate messages to be transmitted before a blast can be initiated. That is, a valid “ARM” command must be received and then (within ten minutes or the system resets) a valid “BLAST” command must be received for power to be applied to the detonator circuit. • Additionally, the valid ARM and BLAST commands are not contained on the PC’s hard disk. Valid commands are read off specially coded external disks, which are kept in a secure location and are only accessed by an authorised person. The safe use of BlastPED requires operational procedures to be put in place by the mine. These are not dissimilar to those used for mains ring systems. Key procedures include: Surface • Only authorised & trained personnel use the system. • All aspects of the system’s use is understood by those • By reducing signal tube consumption (currently approx. involved in its operation, from installing the BlastPED at 300m per shot at an average of 3 shots/week) the system a face, typing in the commands at the PC, to the recovery payback can be very short. of the BlastPED receiver. • Manpower and time costs are signicantly reduced for shot setup and clearance, therefore increased productivity • A system to conrm that all personnel have withdrawn to a safe area before blasting is in place. through better utilisation of your truck/shovel eet. Master Control Unit Two-way Radio Signal Remote Receiver Initiator 17 Darcy Lane West Kalgoorlie WA 6430 Australia PO Box 4200, Kalgoorlie 6430 Tel: +61 8 9022 2300 Fax: +61 8 9022 2311 mstwa@minesite.com.au 15 Duke Street Mt Isa QLD 4825 Australia PO Box 2436 Mt Isa 4825 Tel: +61 7 4749 4922 Fax: +61 7 4749 4933 mstisa@minesite.com.au MST offices also located in Sudbury, Canada and Denver, Pittsburg, Elko and Washington USA Mine Site Technologies Pty Limited reserves the right to make changes to the specifications and information contained in this brochure at any time and without notice. MST-BPD0611-AU Don’t have people in harm’s way – use BlastPED Mine Site Technologies PTY Limited. www.minesite.com.au SYDNEY Blast PED provides a safe, remote blast initiation system for mines by eliminating the high cost of installing and maintaining large firing cable networks, and hence reduce the safety concerns (e.g. induction) associated with these cable based systems. Unit 2 Terminus Business Park 20 Caterpillar Drive Paget QLD 4740 Tel: +61 0447 230180 mst@minesite.com.au this system uses the PED ® Transmission System to communicate with remotely installed receiver/exploders to initiate electric detonators (blasting caps). O P E N C U T S U R FA C E M I N E S AND QUARRIES BlastPED ST Version also known as BlastPED EXEL version was developed for use in surface applications and uses more typical surface radio systems to communicate between a Master Control BlastPED Leaky Feeder Version Unit and a Remote Receiver/Exploder. A key difference use’s a mine’s leaky feeder radio system to communicate to the other two types of BlastPED is this version initiates with remotely installed receiver/exploders to initiate electric signal tube (shock tube) directly, rather than initiating an detonators (blasting caps). electric detonator.

Open the catalog to page 1

Operation Schematic – PED Version for Underground PED ® Loop anten na (Surf ace or U nderg round ) Hard Wired or Fiber Optic Link The LF version operates similarly except the signals are transmitted by the mine’s radio system rather than the PED ® Transmission System Windows PC running Pedcall software for entering messages PED® Modulator with Emergency Message Buttons Ultra Low Frequency signals transmitted through rock strata PED® ULF Transmission Headend Cost Benefits Underground Experience at mines using BlastPED has shown eliminating extensive cabling or signal tube runs can increase...

Open the catalog to page 2All Mine Site Technologies Pty Limited catalogs and technical brochures

-

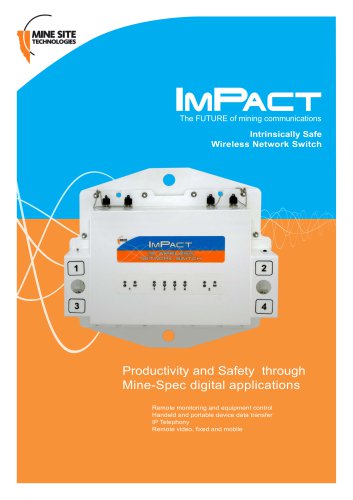

I.S. Wireless Network Switch

2 Pages

-

MP70 I.S. MinePhone

2 Pages

-

BlastPED

2 Pages

-

Asset Tracking

4 Pages

-

VDV

3 Pages

-

Proximity Detection Systems

4 Pages

-

Wireless Repeater Node (WRN)

4 Pages

-

WSN Gateway Unit

4 Pages

-

Remote Telemetry Unit (RTU)

4 Pages

-

VDV Leaky Feeder System

3 Pages

-

ImPact MinePhone (MP-70)

2 Pages

-

ImPact VIP Datasheet

2 Pages

-

Hard Rock Solutions

4 Pages

-

ICCL

2 Pages