Catalog excerpts

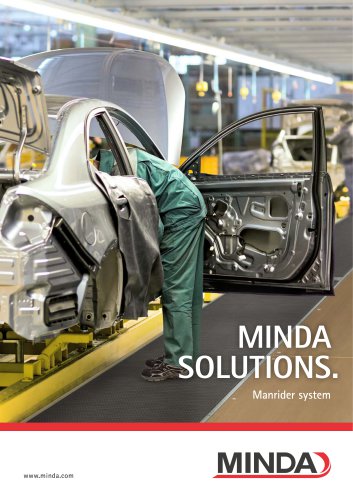

Benefit both the workforce and productivity To create more ergonomic working conditions and boost productivity, the MINDA manrider system move your workforce on cyclical assembly lines. > loor-mounted (requiring no work F on the foundations) > Ready to operate immediately > Jolt-free conveying of workers in perfect sequence Manrider systems make all assembly and inspection jobs very ergonomic. Workers no longer tire themselves out by walking alongside the vehicle and can concentrate on the task at hand. MINDA manrider systems offer clear advantages in this respect: at just 120 mm in height...

Open the catalog to page 2

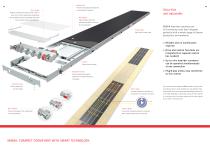

Modular belt Precisely manufactured modular belt, Drive module no tensioning unit required Compact, maintenance-free drive with a slip-on gear unit. The drive modules are exceptionally easy to replace and can be combined with drives from a diverse range of manufacturers. Belt support Plastic sliding surface with optimised coefficient of friction to the modular belt Frame design Rigid, easy-to-align frame MINDA manrider conveyers are full conveying units that integrate perfectly with a whole range of diverse production environments. > Reliable and no maintenance required > Drive and control...

Open the catalog to page 3

Manrider conveyors Convey people wherever Modular, customised motion production requires Dummies These replace the manrider conveyors Make the conveying level when no conveying is taking place wider if more room to manoeuvre’s required Conveyor levels are created from manrider belts, platforms, and ramps, just as the production line requires. Where no conveying is currently required, manrider systems are replaced by dummy. > Quick assembly > Movement only where it’s required > Low investment costs > Exceptional flexibility MINDA manrider conveyors provide movement at the perfect width and...

Open the catalog to page 4

More cycles tomorrow? Fitting conveyors without entailing You can also easily integrate inclined work on the foundations pays sections added in tomorrow’s world dividends. Changes to the production Consistently perfect levels fitted into the existing system Flexibility for tomorrow and way into the future line track are uncomplicated to make On-demand conveying From the dummy to the manrider conveyor, it’s easy to convert in no time When optimising production or changing models, it is no longer necessary to plan around floor conveyor technology installed in pits. – thanks to a grid system...

Open the catalog to page 5

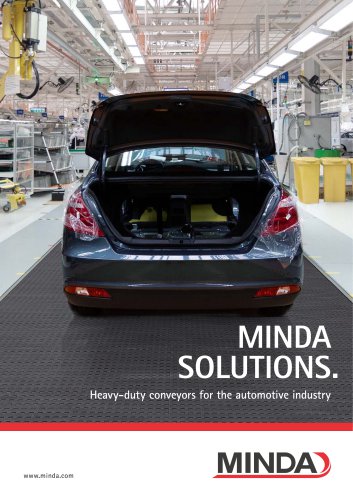

Manrider conveyors Dummies Module length "L" [mm] Various types of dummies can be supplied, as closed units, with lighting, with grating, with trays ... Platforms and ramps Designed to suit the requirements of the production environments.

Open the catalog to page 6

MINDA GmbH Enzer Strasse 121 31655 Stadthagen (GERMANY)

Open the catalog to page 7