Catalog excerpts

Millutensil is a dynamic family business founded in 1955 that has always put its customer first, engineering innovative first-rate solutions based on their needs. The company is known worldwide thanks to the renowned success of its installations. A steadfast internationalisation process and active pursuit of new markets have characterised the activity of MILLUTENSIL since ifs inception. Persistent engagement with our customer propels us to meet their needs with innovative and tailored solutions. Those who know MILLUTENSIL know that it is a business whose principal asset is heart. Each...

Open the catalog to page 3

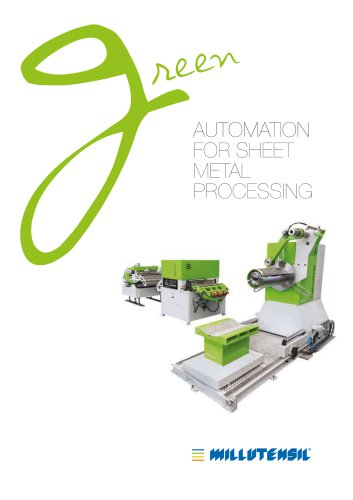

LUBRICATION SYSTEMS DESTACKERS STACKERS WELDING SYSTEMS

Open the catalog to page 4

WE HAVE THE RIGHT SOLUTIONS FoA VouA COMPLETE PROJECT

Open the catalog to page 6

With just one click you will be able to operate the whole line consisting of machines and auxiliary components, like lubrication systems and conveyor belts. Thanks to the "Smart Link System" all systems are smartly interconnected to ensure an accurate process management and optimization. Great saving in terms of reset timing of the line parameters for production changes. OAII processes are included in a single integrated system, which allows a streamlined management of certifications.

Open the catalog to page 7

A01 -2 Aspi svolgitori singoli tipo SLF e SLM da 500 kg a 2000 kg A01-3 Aspi svolgitori singoli tipo SF e SM da 200 kg a 1500kg A01 -4 Aspi svolgitori singoli tipo SFO e SMO da 1000 kg a 3000 kg A01 -5 Aspi svolgitori singoli tipo SFO e SMO da 5000 kg a 30000 kg A01-6 Aspi svolgitori per bobine tipo SMET A01-7 Aspi svolgitori per bobine tipo SB A01-8 Aspi svolgitori per palettes tipo SVE A01 -2 Bnzelabwickelhaspeln Typ SLF und SLM von 500 kg bis 2000 kg A01-3 Bnzelabwickelhaspeln Typ SF und SM von 200 kg bis 1500 kg A01 -4 Bnzelabwickelhaspeln Typ SFO und SMO von 1000 kg bis 3000 kg A01 -5...

Open the catalog to page 8

A05-2-3-4 Aspi per grossi spessori A05-2-3-4 Haspeln fur grosse Dicken A05-2-3-4 Decoilers for high thickness material A05-2-3-4 Derouleurs pour grosses epaisseurs A04-2 Aspi a culla singoli e doppi da 3000 a 10000 kg A04-2 Enzel- und Doppelhaspeln mrt Coilladestuhl von 3000 bis 10000 kg A04-2 Single and double decoilers with loading cradle from 3000 to 10000 kg A04-2 Derouleurs simples et doubles avec berceau de chargement de 3000 a’ 10000 kg A06-2 Culla di carico GF - CFR AQ6-3 Culla di carico CM - CMR AQ6-4 Culla di carico CFT A06-5 Culla di carico CMT A06-6 Sistema multi coil A06-2...

Open the catalog to page 9

B01 -2-3 Ribattatori per pacchi lamiera B01 -4-5-6 Ribattatori per coil B01-2-3 Kipper fur Blechpakete B01 -4-5-6 Kipper fur Coil B01 -2-3 Titters for sheet metal packs B01 -4-5-6 Titter for coil B01 -2-3 Basculeur des tats de metal B01-4-5-6 Basculeur de bobines D01 -2 Raddrizzatrici con testa fissa D01 -3-4 Raddrizzatrici con testa apribile a libro D01 -5 Gruppi di svolgitura e raddrizzatura compatti D01 -2 Richtmaschinen mrt feststehendem Richtkopf D01-3-4 Richtmaschinen mrt aulklappbarem Richtkopf (Krokodilmaul) D01 -5 Kompakte Abwickel- und Richteinheiten D01 2 Straighteners with...

Open the catalog to page 10

c6 o CL CL F01 -2 Raddrizzatrici di predsione c»ntronjllate con testa apribile a libro F01-2 Feinrichtmaschinen mit Stutzrollen, aufldappbarer Richtkopf (Krokodilmaul) F01 -2 Precision straighteners with counter-rollers and lifting head F01 -2 Redresseurs de precision avec contre-rouleaux a tete ouwante D03-2-3-4 Raddrizzatrici per grossi spessori e tranciatura fine D03-2-3-4 Richtmaschinen fur grosse Dicken und Feinstanzen D03-2-3-4 Straighteners for high thickness material and fine blanking D03-2-3-4 Dresseuses pour grosses epaisseurs et decoupage fin E01 -2 Descrizione tecnica...

Open the catalog to page 11

■ G01 -2 Alimentatori nastri a rulli G01 -3 Calandre folli per alimentatori nastri a rulli G01 -4 Turbo feeder G01 -5 Turbo zig-zag feeder G01 -6 Micro feeder ■ G01 -2 Walzenbandvorschube G01 -3 Nicht angetriebene Kalander fur Walzenbandvorschubgerate G01 -4 Turbo feeder G01 -5 Turbo zig-zag feeder G01 -6 Micro feeder ■ G01 -2 Roll feeds G01 -3 Unmotorised material straightening rolls for roll feeders G01 -4 Turbo feeder G01 -5 Turbo zig-zag feeder G01 -6 Micro feeder ■ G01 -2 Amenages de bandes a rouleaux G01 -3 Calandres folles pour amenages des bandes a rouleaux G01 -4 Turbo feeder G01...

Open the catalog to page 12

M01-2-3-4-5-6-7-8 Nastri trasportatori M01-2-3-4-5-6-7-8 Forderbander ■ M01 -2-3-4-5-6-7-8 Conveyor systems ■ M01 -2-3-4-5-6-7-8 Convoyeurs a bande ■ 001-2 Soluzioni per grandi stampi 001-3 Apristampi Blue Line 001 -2 Losungen fur grosse werkzeuge 001 -3 Werkzeugoffner Blue Line 001 -2 Solutions for big dies 001 -3 Die-splitters Blue Line N01 -2-3-4 Rulliere di accompagnamento lamiera alio stampo N01 -2-3-4 Fbrderroller fur Blechbegleitung zur Form N01 -2-3-4 Conveyor rollers to accompany sheet metal to the mold N01 -2-3-4 Rouleaux convoyeurs pour accompagner la tole au moule 001 -2...

Open the catalog to page 13

CONFIGURAZIONE LINEE ANLAGEN KONFIGURATION CONFIGURATION LINES LIGNES DE CONFIGURATION

Open the catalog to page 15

UNA SOLUZIONE IDEALE PER GLI SPAZI RIDOTTI ■ DIE IDEALE LOSUNG BEI GERINGEM PLATZ ■ THE IDEAL SOLUTION FOR SMALL SPACES ■ UNE SOLUTION IDEALE EN CAS D'ESPACE REDUIT UNEA STANDARD STANDARDLY IE 1 - Aspo svolgitore non motorizzato 1 - Nicht angetriebene 2 - Raddrizzatrice Abwickelhaspel 3 - Alimentatore elettronico 2 - Richtmaschine STANDARD UNE 1 - Non powered decoiler 2 - Straightener 3 - Electronic feeder UGNE STANDARD 1 - Devidoir non motorise 2 - Redresseur 3 - Amenage electronique LINEACORTA 1 - Aspo svolgitore motorizzato 2 - Raddrizzatrice/alimentante L’utilizzazione della macchina...

Open the catalog to page 16

LINEA STANDARD E LINEA CORTA CON AVANZATORE A ZIG-ZAG PER PRESSE ■ STANDARD- UND KOMPAKTANLAGE MIT ZIG-ZAG VORSCHUB FUR PRESSEN ■ STANDARD LINE AND SHORT LINE WITH ZIG-ZAG FEED FOR PRESSES ■ LIGNE STANDARD ET LIGNE COURTE AVEC AVANCEUR A ZIG-ZAG POUR PRESSES LINEA STANDARD CON ZIG-ZAG 1 - Aspo svolgitore non motorizzato 2 - Raddrizzatrice 3 - Alimentatore a rulli a Zig-Zag STANDARDANLAGE MIT ZIG-ZAG 1 - Nicht angetriebene Abwickelhaspel 2 - Richtmaschine 3 - Zig-Zag-Walzenbandvorschub STANDARD LINE WITH ZIG-ZAG 1 - Non powered decoiler 2 - Straightener 3 - Zig-Zag roll feeder LIGNE STANDARD...

Open the catalog to page 17All Millutensil catalogs and technical brochures

-

Millutensil - Die-splitter 2016

24 Pages

-

Die & mould spotting presses MIL

40 Pages

-

Die & mould spotting presses BV

28 Pages