Website:

Migatronic Welding Equipment LTD.

Website:

Migatronic Welding Equipment LTD.

Catalog excerpts

SIGMA GALAXY- TAKES WELDING WELDING VALUE HPBSTI?"

Open the catalog to page 1

simplicity and state-of-the-art technology Sigma Galaxy - a new MIG/MAG generation Sigma Galaxy is the result of new giant leaps in welding technology. Developed in co-operation with universities and users throughout the world, this hightechnology welding machine in a self-explanatory industrial design optimizes itself and allows the welder to focus on good workmanship. Abundance of features The Sigma Galaxy contains all the best features from Sigma² plus even more intelligence in the digital softkey control panel; MIG/MAG welding with or without pulse, based on the latest research in arc...

Open the catalog to page 2

Intelligent welding concept makes expert welders even better Digital memory with Migatronic MJC™ The softkey control panel is self-explanatory and based on icons The newly developed MJC™ Miga Job Control allows welders to save up to 200 individual welding jobs, and for every job name saved, additionally nine sequences can be saved which means that the Galaxy can hold as much as 1,800 settings. Lower power consumption less effect on the environment The Sigma Galaxy is green throughout. Its state-of-the-art technology with unmatched performance gives a power consumption that is much lower...

Open the catalog to page 3

Softkey control panel for ease of operation … Clear overview of required information. Setting individual sequences or Sequence Repeat function, designed specifically for position welding. Named and saved job settings can be transferred to other Sigma Galaxy machines or saved on a pc for back-up via SD card. Tack-welding function For quick fixation of the workpiece to all materials. Intelligent sequence combinations giving TIG-like welds. Switch on - press - weld! MJC™ Miga Job Control is an easy-to-use job control function for recall of your favourite settings for repetitive welding...

Open the catalog to page 4

The user-friendly softkey control panel with a large graphic colour display is based on icons and minimizes the risk of faulty attendance by the welder. Individual adjustment of the arc length Supplementary information Description of the chosen job/program Main parameters Setting the amperage, wire feed speed and plate thickness is synergic. Current display Short arc, globular transfer and spray arc. IGC® Intelligent Gas Control: Synergic gas control with correct flow and large-scale gas savings IAC™ Intelligent Arc Control: Automatic prediction of the next milliseconds of the welding...

Open the catalog to page 5

IAC™ Intelligent Arc Control automatically adjusts the arc 50,000 times per second… Sublime welds - quite automatically IAC™ Intelligent Arc Control is a brandnew intelligent and adaptive control of the short arc process for Sigma Galaxy 300 and 400 which automatically handles all changes in the weld pool during the welding process. The result is a 100% stable and focused short arc, colder welding, lower heat input, less distortion and lower power consumption. IAC™ Intelligent Arc Control increases welding speed in vertical downwards welding of root passes. IAC™ Intelligent Arc Control -...

Open the catalog to page 6

Intelligent Gas Control IGC® - synergic gas flow with large-scale reduction of gas consumption 30 Gas consumption at the moment of ignition 20 Gas waste using traditional valve Gas consumption using IGC® 0 0 The more ignitions – the larger gas savings “Gas monitoring” another IGC® feature IGC® also functions as an efficient “gas monitor” that automatically stops the process in case of insufficient gas protection. Intelligent Gas Control Switch on, press, weld..! Better welding, better finish Large-scale reduction of gas consumption IGC® Intelligent Gas Control is a standard feature in the...

Open the catalog to page 7

Migatronic sigma galaxy DATA We reserve the right to make changes. Machine type Mains current, effective, A Power, open circuit, W Power factor Standards, aircooled Standards, watercooled wire feed unit Cooling unit Wire feed speed, m/min. Cooling capacity (1 l/min.), W Torch connection Protection class WELDING VALUE C = Compact, S = Separate wire feed unit 1) The machine meets the requirements for use in areas with increased risk of electric shock. 2) The machine is designed for both indoor and outdoor use. Dealer stamp:

Open the catalog to page 8All Migatronic Welding Equipment LTD. catalogs and technical brochures

-

SIGMA SELECT

8 Pages

-

CALL ME COWELDER

20 Pages

-

AUTOMIG 300 PULSE

4 Pages

-

Robot integration

12 Pages

-

Call Me CoWelder

4 Pages

-

Automig 183

2 Pages

-

FOCUS TIG 160 DC HP PFC

2 Pages

-

Sigma²

8 Pages

-

Omega²

4 Pages

-

Automig² I

4 Pages

-

Omega Mini

2 Pages

-

AUTOMIG

2 Pages

-

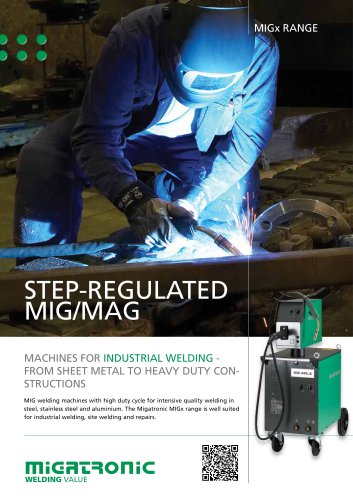

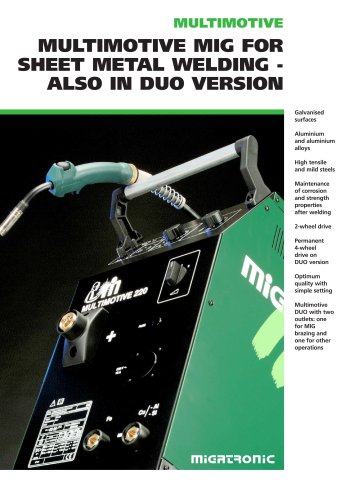

MIG

2 Pages

-

Focus Stick 120E

2 Pages

-

Focus MIG130

2 Pages

-

Focus Stick 160 E PFC

2 Pages

-

Focus TIG 200 AC/DC PFC

2 Pages

-

Focus TIG 200 DC PFC

2 Pages

-

OrderFocus TIG 160 DC PFC

2 Pages

-

Pi

12 Pages

-

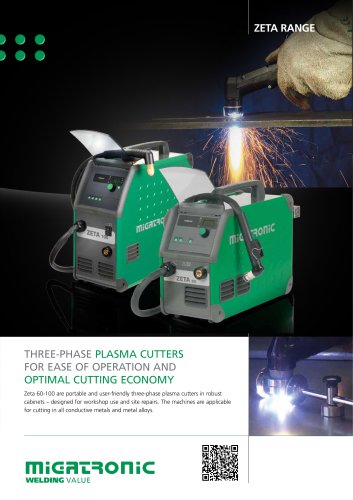

Zeta

2 Pages

-

Pi Plasma

3 Pages

-

MigaLOG

2 Pages

-

EN1090

4 Pages

-

welding torches

40 Pages

-

MIGATRONIC ACCESSORIES

27 Pages

-

RallyMIG 161i

2 Pages

-

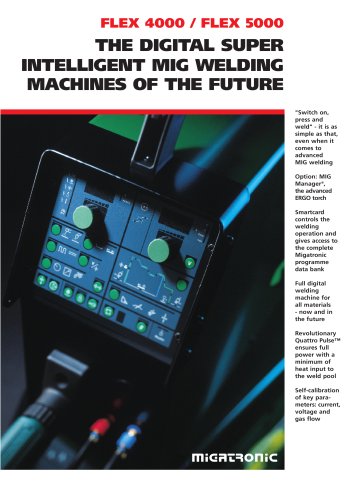

FLEX² 3000

3 Pages

-

Sigma² 300 | 400 | 500

12 Pages

-

TIG Torches

16 Pages

-

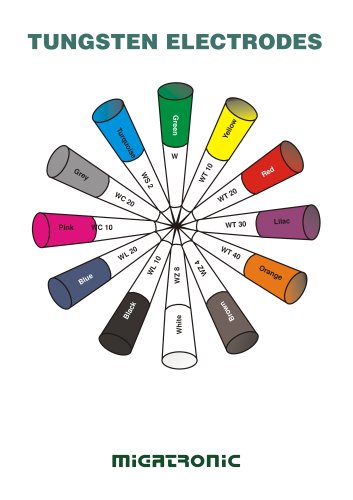

tungsten electrodes

34 Pages

-

Zeta Plasma cutters Series

2 Pages

-

MIG Series

2 Pages

Archived catalogs

-

Robot Integrator

8 Pages