Website:

Migatronic Welding Equipment LTD.

Website:

Migatronic Welding Equipment LTD.

Catalog excerpts

w ROBOT INTEGRATION AUTOMATION OF WELDING PROCESSES PARTNER UP AND GET A SHARE OF our extensive knowhow and experience with robotic welding WELDING VALUE

Open the catalog to page 1

Welding power sources for robot integration complete with peripheral equipment for MIG/MAG, TIG and Plasma welding. Choose a robot integration setup, which matches today's technological requirements. Partner up and get a share of our extensive knowhow and experience with robotic welding. ROBOTIC WELDING ADDS VALUE TO MANUFACTURERS' BUSINESS: • Increased efficiency. Higher welding speed increases production output and lowers production time per workpiece. • Increased production capacity. The increased production output enables manufacturers to attract large orders and to stay competitive. •...

Open the catalog to page 2

Dependability: MIG/MAG, TIG and Plasma welding power sources dedicated to robotic welding deliver dependable performance at all times. Complete packages: The power sources are available in three flexible packages with all peripheral equipment necessary to ensure an efficient robotic welding setup. Efficient communication: High-quality robot control interfaces ensure efficient and correct communication between welding power source and robot. Compatibility: The robot control interface can integrate with all robot brands using anybus or analog/digital I/O communication. Seam tracking: Seam...

Open the catalog to page 3

The RCI4 interface for all robot brands can be built into the power source or delivered as an external unit: • RCI4 I/O, external interface • AnyBus, external interface • AnyBus, internal interface Remote control unit for MIG power sources: • Graphic display • Impact-proof case with adjustable strap and suspension fittings • Shielded signal cable Configurable solutions for AnyBus systems: • EtherNet/IP • PROFINET • DeviceNet • EtherCAT • PROFIBUS The RCI4 for I/O interface for MIG/MAG 1) Optional connects analog/digital I/O signals through a SUB-D-9 and a SUB-D-25 connector. Purchase of...

Open the catalog to page 4

RWF 30 - robot wire feeder for SIGMA SELECT (MIG) with four-roll wire feed system and built-in functions. Water coupling and current coupling are equipped with screw fastening ROBOT CONTROL INTERFACE: RCI4 RCI4 Anybus Box for Sigma Select RCI4 ANYBUS robot interface (built in Sigma Select)

Open the catalog to page 5

MIG/MAG WELDING POWER SOURCES AND PERIPHERAL EQUIPMENT MIG SOLUTIONS MIG POWER SOURCES OPTIONAL WELDING PROGRAM PACKAGES Sigma Select Robo 300 Mild steel Sigma Select Robo 400 Stainless steel Sigma Select Robo 550 MIG POWER SOURCES INCLUDE Individual programs Graphic control panel incl. 0.5 m cable Diffusion-slow gashose, 2.7 m OPTIONAL EQUIPMENT Standard welding program package (Synergic function required) Field bus module Trolley MANDATORY EQUIPMENT Interconnection with plug for RWF – Air Air-cooled or water-cooled power source incl. flow control Interconnection with plug for RWF – Water...

Open the catalog to page 6

SIGMA SELECT ROBO Sigma Select ROBO 300, 400 and 550 A three-phase power sources for MIG/MAG welding of all materials. The power sources can be upgraded throughout their service lives by adding programs and functions according to requirements. Sigma Select ROBO is designed for intelligent welding beyond the ordinary.

Open the catalog to page 7

ROBOT CONTROL INTERFACE The RCI2 for TIG and Plasma is connected to the power source via CAN-bus and enables the user to choose between hardwired transfer of both digital and analog I/O signals or Fieldbus-based transfer of signals between robot controller and power source. The RCI2 interface for all robot brands is a configurable solution for AnyBus systems: • EtherNet/IP • PROFINET • DeviceNet • EtherCAT • PROFIBUS EXTRA COOLING UNIT WIRE COIL HOLDER External cooling of plasma torch for high performance and high duty cycle. External mounting of wire coil for TIG and Plasma: • Suits wire...

Open the catalog to page 8

COLD WIRE FEEDER Cold Wire Feeder: four-roll wire feed system, synchronised pulse on wire and memory for individual settings ROBOT CONTROL INTERFACE RCI2 I/O interface prepared for anybus communication.

Open the catalog to page 9

TIG // PLASMA WELDING POWER SOURCES AND PERIPHERAL EQUIP PI ROBO Pi ROBO 350 and 500 A power sources for TIG welding of mild and stainless steel and aluminium, with or without pulse function. Pi power sources are designed for heavy duty welding with intelligent functions for improved efficiency and welding quality. TIG POWER SOURCES Pi 350 DC W Pi 350 AC/DC W Pi 500 Robo DC W Pi 500 Robot AC/DC W TIG POWER SOURCES INCLUDE RCI² I/O interface prepared for digital and analog communication incl. 6 m cable CAN plug incl. CAN distributor box Remote control plug incl. Arc Detect signal IGC® -...

Open the catalog to page 10

PLASMA SOLUTIONS PLASMA POWER SOURCE PI PLASMA Pi Plasma 350 is a high-performance power source for welding mild and stainless steel, with or without pulse function. It ensures uniform, high-quality welds in the 5-350 A current range. PLASMA POWER SOURCE INCLUDES RCI² I/O interface prepared for digital and analog communication incl. 6 m cable IGC® - Intelligent Gas Control with flow control Double CAN plug incl. CAN distributor box Remote control plug incl. Arc Detect signal Built-in water flow control Diffusion-slow gashose, 2.7 m MANDATORY EQUIPMENT Rack or standard trolley/wheels...

Open the catalog to page 11

TECHNICAL DATA We reserve the right to make changes. POWER SOURCE MIGATRONIC A/S Aggersundvej 33 DK-9690 Fjerritslev, Danmark Tel: (+45) 96 500 600 migatronic.com miGRkRomcWELDING VALUE

Open the catalog to page 12All Migatronic Welding Equipment LTD. catalogs and technical brochures

-

SIGMA SELECT

8 Pages

-

CALL ME COWELDER

20 Pages

-

AUTOMIG 300 PULSE

4 Pages

-

Call Me CoWelder

4 Pages

-

Automig 183

2 Pages

-

FOCUS TIG 160 DC HP PFC

2 Pages

-

Sigma Galaxy

8 Pages

-

Sigma²

8 Pages

-

Omega²

4 Pages

-

Automig² I

4 Pages

-

Omega Mini

2 Pages

-

AUTOMIG

2 Pages

-

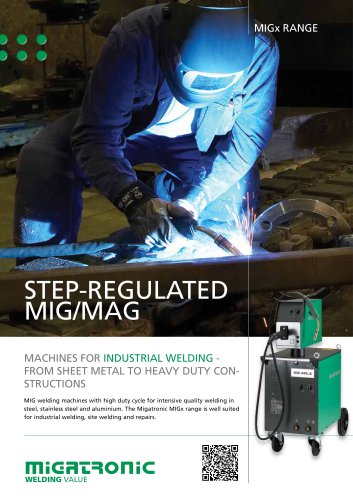

MIG

2 Pages

-

Focus Stick 120E

2 Pages

-

Focus MIG130

2 Pages

-

Focus Stick 160 E PFC

2 Pages

-

Focus TIG 200 AC/DC PFC

2 Pages

-

Focus TIG 200 DC PFC

2 Pages

-

OrderFocus TIG 160 DC PFC

2 Pages

-

Pi

12 Pages

-

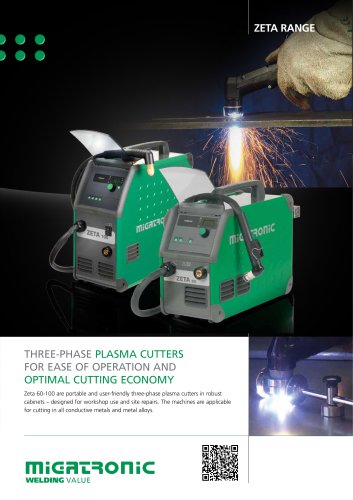

Zeta

2 Pages

-

Pi Plasma

3 Pages

-

MigaLOG

2 Pages

-

EN1090

4 Pages

-

welding torches

40 Pages

-

MIGATRONIC ACCESSORIES

27 Pages

-

RallyMIG 161i

2 Pages

-

FLEX² 3000

3 Pages

-

Sigma² 300 | 400 | 500

12 Pages

-

TIG Torches

16 Pages

-

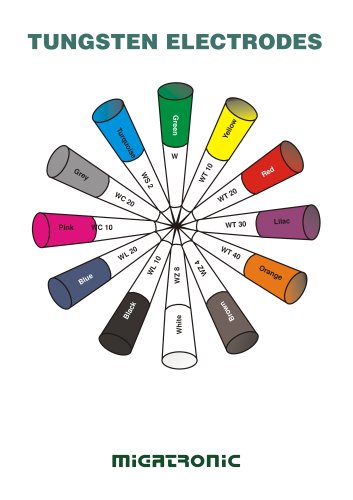

tungsten electrodes

34 Pages

-

Zeta Plasma cutters Series

2 Pages

-

MIG Series

2 Pages

Archived catalogs

-

Robot Integrator

8 Pages