Website:

Migatronic Welding Equipment LTD.

Website:

Migatronic Welding Equipment LTD.

Catalog excerpts

Migatronic Pi – also suitable for automation Robust and reliable welding quality Migatronic Pi are user-friendly welding machines, which meet every need for TIG and MMA welding. Highperformance inverter machines for precision welding in mild steel, stainless steel, aluminium and other high-alloy materials. All Pi machines are delivered with coated PCB’s and carry Eurocodes calibration certificate. There is a Migatronic Pi machine for any type of welding operation: repair, assembly, construction, industry and robot. Processes include TIG HP (highfrequency with pulse), TIG H (without pulse),...

Open the catalog to page 2

More automation and super design – for both manual and automatic/robot welding Migatronic’s Pi range covers the entire spectrum from portable on-location versions to dedicated special and heavy duty machines with up to 500 A for automatic/robot welding.

Open the catalog to page 3

advanced functions at hand Migatronic’s Pi machines combine proven inverter technology with new control and communication options. These features optimise welding performance and make the most advanced functions child’s play to use. New pulse sound with Synergy PLUS™ In addition to traditional pulse and quick pulse for TIG DC, Pi offers the Migatronic invention Synergy PLUS™; A special pulse function where the machine automatically and dynamically sets all primary pulse parameters when welding in synergy mode. The traditional sound of pulse welding has therefore been replaced by clean...

Open the catalog to page 4

Award-winning user-friendly design with functional details AC welding: one button – four parameters The art of simplification: On the Pi AC/DC versions, the welder can adjust four primary AC parameters using just one button: 1 Time balance - overall control of cleaning effect 2 AC frequency - arc control and control of weld pool 3 Electrode preheating - perfect ignition and reduced electrode wear - ready for new gas types 4 Current balance - maintains a DC-like tungsten tip ensures arc focus D.O.C® - quicker AC welding All Pi AC machines are equipped with D.O.C.® function (Dynamic Oxide...

Open the catalog to page 5

Four different control panels with optimized operational comfort Technique is for the sake of man, not the other way round. That is why the design of the control panel was an ambitious development project in itself with focus on welding value…! The result is a logical and icon-based control panel. The software in the control panel meets future demands. The machines are easily adjustable according to new user-defined applications. 4-AC balance parameters TIG-A-Tack function 4 x 64 program settings* Pi AC/DC with D.O.C® TIG AC/DC control panel with all relevant parameters for professional...

Open the catalog to page 6

Migatronic Pi – it’s quite simple Quick change-over between jobs Press one button and change over between up to 64 different fixed settings in the welding process chosen. Activate Synergy PLUS™ and Pi automatically sets all primary pulse parameters (synergy mode). TIG-A-Tack™: a quick and extremely precise function with ultra-small tacks. Pi 350 MMA CELL Pi 350 MMA CELL is designed specifically for tube/pipeline welding and vertical downwards welding position using cellulose electrodes. This means considerably increased welding speed, increased melting performance and higher efficiency. Pi...

Open the catalog to page 7

Intelligent Gas Control IGC® Synergic gas flow with large-scale reduction of gas consumption IGC® offers more advantages for the industrial machines Intelligent gas post flow, a special feature for use with IGC®, is dedicated to the large Pi machines (350 and 500). It automatically provides the required gas post flow time, and oxidized tungsten electrodes and welds are eliminated at finalizing welds. Intelligent gas Control Intelligent Gas Control IGC® is a configurable option for Pi 350 and Pi 500 for TIG. An efficient gas-saver kit combined with dynamic gas control that monitors...

Open the catalog to page 8

The Pi can be customised to any welding situation - including automated devices and robots Automated TIG welding The two largest TIG inverters, the Pi 350 and 500, are obvious power sources for automatic devices/robots and prepared for communication with a robot or automatic device in a setup with the CWF Multi. Extra identical control panel RWF - Robot Wire Feeder. The operating comfort follows the operator All Pi machines for automated welding processes can be equipped with an extra identical control panel at the robot cell where the robot operator gets the same functions and facilities...

Open the catalog to page 9

CWF Multi ensures uniform quality and high welding speed TIG welding non-stop Automatic wire-feeding CWF Multi (Cold Wire Feeder) is a separate wire feed unit designed specifically for setups with automatic devices and for optimization of manual TIG welding. For optimization of welding quality and speed, the TIG torches can be fitted with special equipment for automatic wire feeding. The CWF Multi control panel allows the welder to switch between programs and features automatic wire-feeding synchronously with the machine’s pulse function (Pi 350-500). All Pi machines can via CWF Multi feed...

Open the catalog to page 10

Flexible range of accessories and welding hoses offering new advantages TIG torches for quality welding Three control units improve the efficiency The torch is the welder’s auxiliary arm and quite decisive for the welding result. That is why Migatronic develops and designs its own comprehensive range of ergonomically correct welding torches; The TIG Adjust, for example, can be turned in any direction and TIG Flex is flexible and can be shaped to a welding angle of choice. The Migatronic TIG Ergo torches can be equipped with three optional control units for adjustment of the welding current...

Open the catalog to page 11

We reserve the right to make changes. Mains current, effective, A Open circuit voltage, V Application class Protection class Duty cycle cooling unit Cooling output 1 l/min., W Tank capacity, liter Weight incl. fluid, kg *) Separate cooling unit for Pi 200/250. **) Separate cooling unit for Pi 350. ***) Integrated cooling unit in Pi 350 AC/DC / Pi 500 DC-AC/DC. WELDING VALUE Dealer stamp:

Open the catalog to page 12All Migatronic Welding Equipment LTD. catalogs and technical brochures

-

SIGMA SELECT

8 Pages

-

CALL ME COWELDER

20 Pages

-

AUTOMIG 300 PULSE

4 Pages

-

Robot integration

12 Pages

-

Call Me CoWelder

4 Pages

-

Automig 183

2 Pages

-

FOCUS TIG 160 DC HP PFC

2 Pages

-

Sigma Galaxy

8 Pages

-

Sigma²

8 Pages

-

Omega²

4 Pages

-

Automig² I

4 Pages

-

Omega Mini

2 Pages

-

AUTOMIG

2 Pages

-

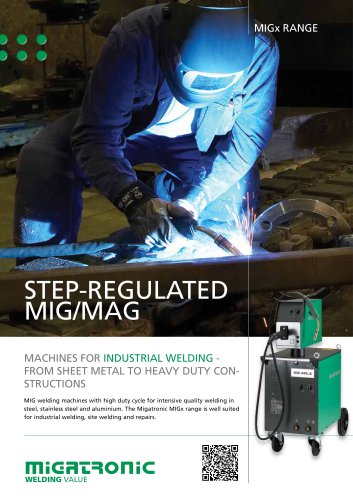

MIG

2 Pages

-

Focus Stick 120E

2 Pages

-

Focus MIG130

2 Pages

-

Focus Stick 160 E PFC

2 Pages

-

Focus TIG 200 AC/DC PFC

2 Pages

-

Focus TIG 200 DC PFC

2 Pages

-

OrderFocus TIG 160 DC PFC

2 Pages

-

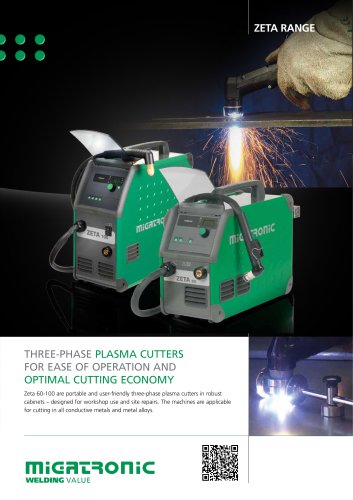

Zeta

2 Pages

-

Pi Plasma

3 Pages

-

MigaLOG

2 Pages

-

EN1090

4 Pages

-

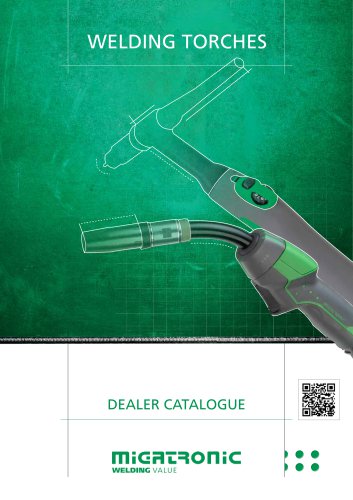

welding torches

40 Pages

-

MIGATRONIC ACCESSORIES

27 Pages

-

RallyMIG 161i

2 Pages

-

FLEX² 3000

3 Pages

-

Sigma² 300 | 400 | 500

12 Pages

-

TIG Torches

16 Pages

-

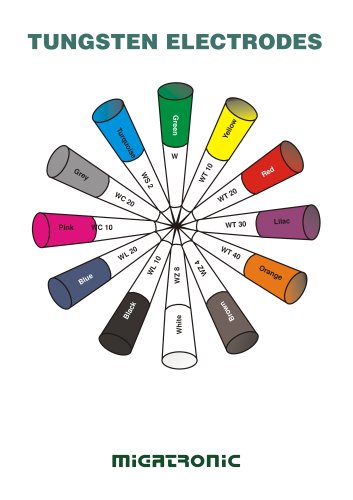

tungsten electrodes

34 Pages

-

Zeta Plasma cutters Series

2 Pages

-

MIG Series

2 Pages

Archived catalogs

-

Robot Integrator

8 Pages