Website:

Migatronic Welding Equipment LTD.

Website:

Migatronic Welding Equipment LTD.

Catalog excerpts

BUILT IN SAFETY SYSTEM CE APPROVED ... ... COWELDER A COLLABORATIVE WELDING ROBOT

Open the catalog to page 1

MAXIMUM FLEXIBILITY CoWelder is a complete welding robot solution, all parts supplied, ready to install in an existing production. It makes the production of workpieces more efficient no matter the quantity and frequency. This is an affordable step into welding automation. • Reduced arc time per weld • Increased production capacity • Optimum welding quality • Gas savings • Operators need no welding skills • Safe, flexible, compact solution • Easy programming and verification

Open the catalog to page 2

A NEW WELDING ASSISTANT The CoWelder is possibly the smartest and smallest automated welding solution on the market. It joins the family of cobots: collaborative robots working together with humans in a shared workspace. The CoWelder can improve your small and large batch component production, delivering uniform welds of continuous high quality. With this flexible and easy-to-program cobot you can increase work efficiency, releasing skilled welders for other tasks, therefore saving time and costs. FLEXIBILITY IS THE KEY A high-performance Migatronic welding machine and the CoWelder are a...

Open the catalog to page 3

MAXIMUM FLEXIBILITY EASY INSTALLATION AND PROGRAMMING It takes little time to install the CoWelder in your existing production and you can start welding on the first day. Mount the CoWelder on your welding table, turn on your welding assistant and start programming. Programming the CoWelder is simple and intuitive. Staff with no programming experience can easily learn how to operate the cobot. Build up a catalogue of workpieces each with an attached program and switch between them as required during a workday. USING MIGATRONIC TEMPLATES Teach the cobot and it will remember your movements...

Open the catalog to page 4

It used to take at least twice the amount of time for the same volume of production. For some components, we are able to reduce delivery time from two weeks to one. Torsten Lezius, CEO, L&S Technischer Handel GmbH, Germany MAXIMUM FLEXIBILITY

Open the catalog to page 5

The CoWelder product packages match customers' requirements for optimum welding performance; from simple welding to highly sophisticated pulse MIG or TIG welding (with or without cold wire feeding). Choose between UR5 and UR10 robot - depending on the requested maximum working radius. 01 Balancing holder 02 Rear protective cover 03 Power Source 04 Start/stop unit with 5m cable 05 Teach pendant 06 Mobile table mount, auto-balancing system 07 Free drive button 08 UR robot arm MIG/MAG Power source. Features DC welding and various Migatronic technologies such as IGC® (Intelligent Gas Control)...

Open the catalog to page 6

MAXIMUM FLEXIBILITY IN THE SUPPLY OF THE PRODUCT PACKAGES THE FOLLOWING IS INCLUDED: Start/stop unit with 5 m cable Robot welding torch, 4 m length Standard robot torch holder Mobile table mount, autobalancing system Migatronic programming templates IGC® Intelligent Gas Control Calibration certificate CE-marking Instruction manual • UR robot • Free drive button on the 6th joint of the robot arm for easy programming of the robot • Robot controller incl. teach pendant with E-stop and 5 m cable • ARC safety control. Ensuring the robot will only process/weld when a welding arc is present. •...

Open the catalog to page 7

MAXIMUM FLEXIBILITY Our time saved per workpiece is about 50 %. We produce from 10 to 1000 workpieces at a time. Our efficiency gains are 30-40 % owing to the easy switching between programs and welded workpiece. And this is just the beginning … Jens Christian Lægsgaard, General Manager, MVI Maskinfabrik, Denmark 8

Open the catalog to page 8

MAXIMUM FLEXIBILITY EASY AND INEXPENSIVE VERIFICATION OF PROGRAMS On the CoWelder, as opposed to traditional robots, program verification is easy and inexpensive. Arc control is a unique function, which enables program verification without welding, so you avoid spending money on expensive samples. The built-in counter function makes it easy to measure the welding cycle time and verify whether new optimisation ideas can be realised, for example by changing the robot arm position before start. MOBILE AT ANYTIME The CoWelder solution is easy to move around as required, using a forklift. You...

Open the catalog to page 9

MIG/MAG POWER SOURCES OMEGA 300 COWELDER ADVANCED CONTROL PANEL The Omega 300 CoWelder, a compact air-cooled MIG/MAG inverter, is perfect for welding in mild steel. The machine features more than 70 synergic welding programs. Advanced, yet simple. Add all the functions you want for Omega to match your exact needs. Features MIG brazing and automatic functions for easier welding. The Omega 300 CoWelder package is ideal for simple MIG/MAG welding tasks. Omega 300 CoWelder includes IGC® (Intelligent Gas Control). IGC saves gas, optimises gas protection and improves welding quality. Advanced...

Open the catalog to page 10

MAXIMUM FLEXIBILITY SIGMA SELECT 400 GRAPHIC CONTROL PANEL The Sigma Select 400, a compact MIG/MAG welding machine, is ideal for complicated welding task. It is tough, versatile and built to meet the future. Built to meet the future Choose Synergic or Pulse with or without IAC*) and upgrade if your needs change. The digital soft-key control panel is prepared for multiple add-ons including automatic functions for easier welding. Pick it up and take it with you. You will find a wide selection of CoWelder packages to choose from. The machine comes with a well-assorted standard program package,...

Open the catalog to page 11

SIGMA SELECT FUNCTIONS SEQUENCE REPEAT Tab your way to the perfect settings Get stunning TIG-like welds with a MIG/MAG welding machine. DUO Plus technology automatically ensures a perfect final touch. It works in all materials, for all welding positions and all welders can do it. It’s quite simple. The Sequence function makes it possible for you to save up to 9 personal sequences in each welding program. Switch between them with just a tap on the welding torch.Use Sequence for mounting and assembly, for instance where welders carry out many different welds during their workday. The Sequence...

Open the catalog to page 12

MAXIMUM FLEXIBILITY IAC INTELLIGENT ARC CONTROL AUTOMATICALLY ADJUSTS THE ARC 50,000 TIMES PER SECOND... Real time laboratory records showing full control of the IAC process, also during droplet pinch-off. SIMPLIFY COMPLEX WELDS IAC (Intelligent Arc Control) makes difficult downward welding of root passes easy, even for less experienced welders. With a 100% stable and focused short arc, you achieve complete fusion in root passes. This increases the quality of each weld and your product. WELD A SOLID FOUNDATION Use IAC to make the first joint, the root pass. IAC makes sure that fusion in...

Open the catalog to page 13All Migatronic Welding Equipment LTD. catalogs and technical brochures

-

SIGMA SELECT

8 Pages

-

AUTOMIG 300 PULSE

4 Pages

-

Robot integration

12 Pages

-

Call Me CoWelder

4 Pages

-

Automig 183

2 Pages

-

FOCUS TIG 160 DC HP PFC

2 Pages

-

Sigma Galaxy

8 Pages

-

Sigma²

8 Pages

-

Omega²

4 Pages

-

Automig² I

4 Pages

-

Omega Mini

2 Pages

-

AUTOMIG

2 Pages

-

MIG

2 Pages

-

Focus Stick 120E

2 Pages

-

Focus MIG130

2 Pages

-

Focus Stick 160 E PFC

2 Pages

-

Focus TIG 200 AC/DC PFC

2 Pages

-

Focus TIG 200 DC PFC

2 Pages

-

OrderFocus TIG 160 DC PFC

2 Pages

-

Pi

12 Pages

-

Zeta

2 Pages

-

Pi Plasma

3 Pages

-

MigaLOG

2 Pages

-

EN1090

4 Pages

-

welding torches

40 Pages

-

MIGATRONIC ACCESSORIES

27 Pages

-

RallyMIG 161i

2 Pages

-

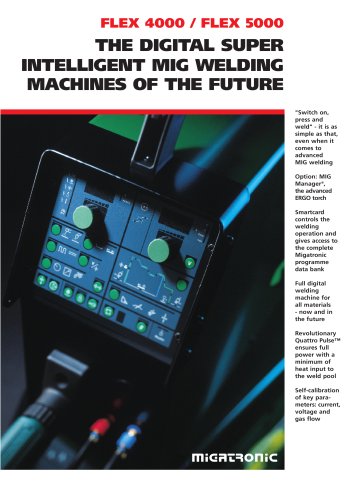

FLEX² 3000

3 Pages

-

Sigma² 300 | 400 | 500

12 Pages

-

TIG Torches

16 Pages

-

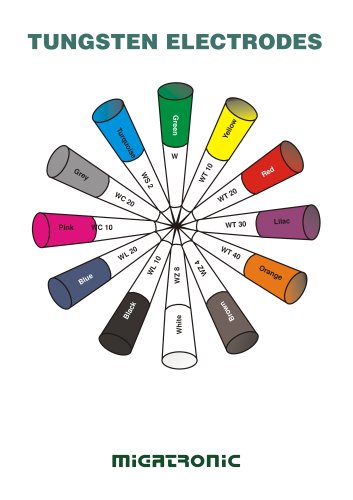

tungsten electrodes

34 Pages

-

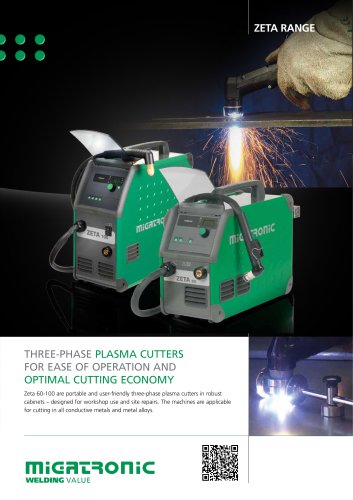

Zeta Plasma cutters Series

2 Pages

-

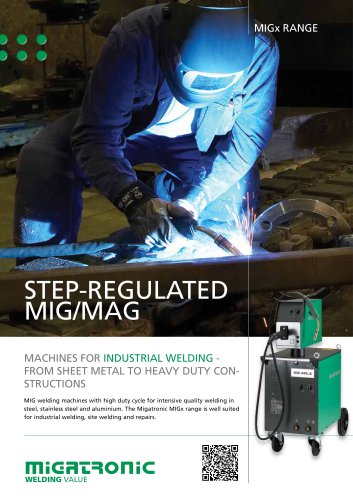

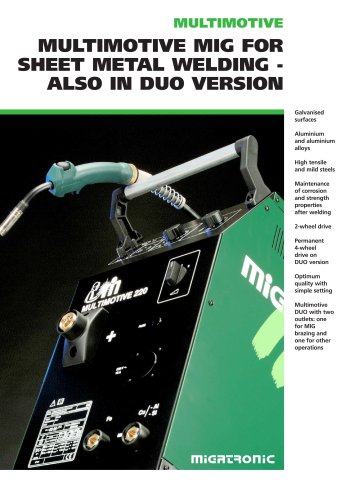

MIG Series

2 Pages

Archived catalogs

-

Robot Integrator

8 Pages