Catalog excerpts

Sigma2 - the new switch on-press-weld generation for advanced MIG/MAG New welding generation – the future starts here Migatronic Sigma2 is the second generation of the popular Sigma range of power sources with a maximum output of 300, 400 and 500 A respectively. Available in C (Compact) or S (with separate wire-feed unit) versions and combinable with four different control panels. With or without pulse and with infinitely variable adjustment of all parameters, the Sigma2 machines are designed for advanced MIG/MAG welding of all types of materials - in trades and assembly, heavy industry,...

Open the catalog to page 2

You make the demands - we “tailor” the ideal welding machine solution Some of the Sigma2 family. Note the functional design. The machines shown may be illustrated with extra equipment. 3

Open the catalog to page 3

Four control panels designed for future updates 61113475C BASIC 61113475C MIG/MAG characteristic BASIC MMA characteristic PULSE 61113487A Pulse 61113475C Basic for simple and routine welding jobs. With fine adjustment of all secondary parameters. Advanced featuring DUO Plus™ and sequence spaces for user-defined parameter settings and fine-tuning. 5 DUO PlusTM BASIC 61113487A Two-stroke or four-stroke SYNERGIC 61113487A 5 5 Synergic with built-in DUO Plus™ and full synergy between parameters, for MIG brazing, etc. Program package Standard Tack-welding function SYNERGIC Pulse featuring up to...

Open the catalog to page 4

Operational comfort in a class by itself - Switch on, press, weld … Quick changeover between jobs DUO Plus™ - better finish with increased automatic process The DUO Plus™ function optimises control of the weld pool and reduces the heat input. DUO Plus™ is an automatic enhancement of traditional MIG/MAG sequence welding. 61113487A Set primary parameters: welding current, wire feed speed or thickness of material. 5 The machine puts the finishing touches to the welding result. DUO Plus™ – Aluminium 61113487A Fine-tuning: welding voltage/trim, arc adjust or seam average log. YNERGIC The...

Open the catalog to page 5

Green technology is of benefit to the environment and bottom line profitability kWh 8000 Example of power consumption - Sigma2 vs. old technologies (schematic diagram) Conditions: 7000 Arc time: 3 hours/day 6000 Standby: 5 hours/day 5000 Welding current: 240 A 4000 Electricity cost: 0.12 € / kWh 3000 2000 1000 0 Thyristor with standby MIG - 500 A Stepregulated MIG - 500 A Thyristor without standby MIG - 500 A Sigma2 MIG 500 A Annual power consumption: 858 €* Annual saving: Up to 245 € *) Thyristor without standby: 220 days x 8 hours = 7,000 kWh x 0.12 = 858 € Lower power consumption - less...

Open the catalog to page 6

Intelligent Gas Control IGC® Synergic gas flow with large-scale reduction of gas consumption Intelligent Gas Control - Switch on, press, weld ..! Better welding, better finish Intelligent Gas Control IGC® is designed specifically for Sigma2 as a configurable option. An efficient gas-saver kit combined with dynamic gas control that monitors consumption and optimises gas protection for the chosen synergic welding program. Under favourable conditions, IGC® may give gas savings in excess of 50% with proportionally fewer replacements of gas cylinder to the benefit of economy, environment and...

Open the catalog to page 7

Multi-functional trolley column handles every combination... Prizewinning design that can carry a little extra Extra wire-feed unit: e.g. Pi 200/250 or Zeta 40/60 The unique “backbone” can be used for a double version with two wire-feed units or a triple version combining Sigma2 (MIG/ MAG) with Migatronic Pi (TIG) or Zeta (plasma cutter). Sigma is characterised throughout by Migatronic's new design, which received the iF Product Design Award. New intelligent Sigma2 advantages: • Intelligent Gas Control IGC® • ncreased memory with the I possibility of more program packages • D card for...

Open the catalog to page 8

Special edition - for shipyards and other heavy industries Offshore equipment – robust in every detail Migatronic has developed a quite new offshore concept consisting of trolley, autotransformer, protective brackets, fittings etc. All in galvanised finish for extra protection of PCBs and plug connections, especially targeted at shipyards and other heavy industries. Safety is in focus which is underlined by a number of solid functions, such as extra large trolley wheels, crane lift eyes, and fork-lift truck side members in addition to a special platform for MWF 50/55 Yard, cable suspension,...

Open the catalog to page 9

Custom-built solutions - Sigma2 is configurable for any welding application Power supply via autotransformer Portable wire-feed unit with industrial wire-feeding It is a question of functionality and high performance under all voltage conditions. With an autotransformer incorporated in the “chassis” of the multifunctional column, the Sigma2 is safeguarded against undesirable voltage fluctuations in the 230500 V range. For Sigma2, Migatronic has developed the MWF 41, a compact, portable wire-feed unit (30 m/ min. wire-feed speed), that combines the limited dimensions of the open type with...

Open the catalog to page 10

Automated welding with Sigma2 in a complete robot setup Robot interface Robot concept – fully operational with all units RWF Multi The two largest Sigma2 machines in “automated trim” are designed for integration with robots and automated devices along with RWF Multi. I/O robotinterface is the communication interface between the CAN-BUS power source and robot or automated device. RWF Multi is a wire feed unit that feeds wire from a spool or drum through an intermediary cable into the robot torch. RWF Multi can also be used as a separate wire-feed unit with wirereel holder for manual welding...

Open the catalog to page 11

Sigma2 300 | 400 | 500 Machine type Sigma2 300 Mains voltage +/÷ 15% (50-60Hz) Sigma2 400 3 x 400 V (3 x 230-500 V*) Sigma2 500 3 x 400 V 3 x 400 V Fuse 16 A 20 A 32 A Effective mains current 15.7 A 17.3 A 25.8 A Mains current, max. 18.1 A 28.0 A 44.9 A Open circuit power 40 W 40 W 40 W Efficiency factor 0.90 0.90 0.90 Efficiency rate 0.85 0.85 0.85 Current range 15-300 A 15-400 A 40-500 A Duty cycle, 20°C (MIG/MAG) 300 A/100% 330 A/100% 475 A/100% Duty cycle, 20°C (MIG/MAG) - 400 A/70% 500 A/80% Duty cycle, 40°C (MIG/MAG) 270 A/100% 290 A/100% 420 A/100% Duty cycle, 40°C (MIG/MAG) 300...

Open the catalog to page 12All Migatronic Welding Equipment LTD. catalogs and technical brochures

-

SIGMA SELECT

8 Pages

-

CALL ME COWELDER

20 Pages

-

AUTOMIG 300 PULSE

4 Pages

-

Robot integration

12 Pages

-

Call Me CoWelder

4 Pages

-

Automig 183

2 Pages

-

FOCUS TIG 160 DC HP PFC

2 Pages

-

Sigma Galaxy

8 Pages

-

Sigma²

8 Pages

-

Omega²

4 Pages

-

Automig² I

4 Pages

-

Omega Mini

2 Pages

-

AUTOMIG

2 Pages

-

MIG

2 Pages

-

Focus Stick 120E

2 Pages

-

Focus MIG130

2 Pages

-

Focus Stick 160 E PFC

2 Pages

-

Focus TIG 200 AC/DC PFC

2 Pages

-

Focus TIG 200 DC PFC

2 Pages

-

OrderFocus TIG 160 DC PFC

2 Pages

-

Pi

12 Pages

-

Zeta

2 Pages

-

Pi Plasma

3 Pages

-

MigaLOG

2 Pages

-

EN1090

4 Pages

-

welding torches

40 Pages

-

MIGATRONIC ACCESSORIES

27 Pages

-

RallyMIG 161i

2 Pages

-

FLEX² 3000

3 Pages

-

TIG Torches

16 Pages

-

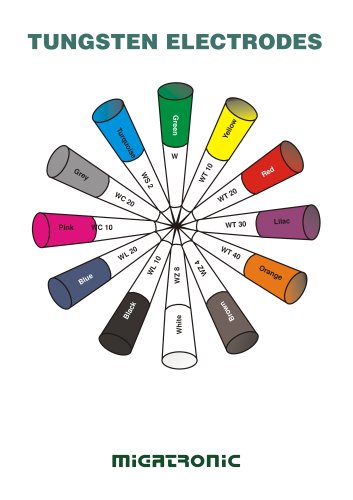

tungsten electrodes

34 Pages

-

Zeta Plasma cutters Series

2 Pages

-

MIG Series

2 Pages

Archived catalogs

-

Robot Integrator

8 Pages