Catalog excerpts

FULLY DIGITAL SOLUTION WELDING PROCESSES WELDING VALUE

Open the catalog to page 1

Integrator solution for au MIG, TIG and PLASMA weldin Being one of Europe’s leading developers and manufacturers of welding solutions, Migatronic has been a trusted provider of equipment for automated solutions for more than four decades. Our background and core expertise are welding and welding technology – and we know how to make welding processes function optimally via interface, hardware and well thought-out software in modern welding equipment. Simple solutions Based on experience from more than 2,000 individual welding installations, we can provide straightforward and reliable...

Open the catalog to page 2

Sigma Galaxy Project responsibility • IGC® - Intelligent Gas Control • IAC™ - Intelligent Arc Control • MJC™ - Miga Job Control • Power Arc™ • Sequence Repeat™ Welding machines Welding technology Customer contact System integration Robot Commissioning Approval Product knowhow Operators’ knowledge Pi • TIG-A-Tack™ - tack welding function • D.O.C.® - Dynamic Oxide Control • Synergy PLUS™ - dynamic pulse • IGC® - Intelligent Gas Control Pi Plasma • Synergy PLUS™ - dynamic pulse • IGC® - Intelligent Gas Control • Plasma-melt, Plasma-press, Plasma-keyhole • TIG-A-Tack™ - tack welding function...

Open the catalog to page 3

THE FLEXIBLE RCI² robot Control Interface Analog/digital interface for MIG, TIG/PLASMA welding processes • For all types/makes of robots Welding torches and collision protection are not included in the standard solutions. • Configurable solutions for the following BUS systems: Please contact Migatronic for further information. - EtherNet/IP - PROFINET - PROFIBUS - DeviceNet - EtherCAT - Migatronic CAN/Analog I/O • Touch Sensing • Prepared for seam tracking system remote MIG² Remote control unit for MIG welding machine • Graphic display • Impact-proof case with adjustable strap and...

Open the catalog to page 4

RWF² Robot wire feeder MIG/MAG compact tacho-feeder with four-roll wire feed system • Built-in functions, e.g. IGC®, supporting Migatronic MIG welding processes • Built-in Air Blow system for cleaning of gas nozzle using compressed air • Touch Sensing MIGALOG™ Digital data collection – MIG • Transfer from machine via SD card to a PC for storage Water coupling and current coupling are equipped with screw fastening • For documentation, spot checks and procedures CWF TIG/PLASMA cold wire feeder TIG/PLASMA feeder with four-roll wire feed system • Built-in functions, e.g. synchronised pulse on...

Open the catalog to page 5

tailored automation solutions These MIG, TIG and Plasma automation solutions which can be tailored with mandatory and optional equipment, meet the requirements for mechanical integration and analog or digital communication with most makes of robots. Sigma Galaxy 500 ROBO S-W The above MIG power sources include RCI² analog interface prepared for digital communication incl. 6 m cable The above TIG power sources include Remote MIG² graphic display remote control incl. 6 m cable Built-in water flow control RCI² analog interface prepared for digital communication incl. 6 m cable MigaLOG™ licence...

Open the catalog to page 6

Universal analog/Fieldbus interface for communication between welding equipment and robot controller. Plasma solutions Plasma power source Fieldbus module – MIG/TIG/PLASMA interface/robot communication PROFIBUS DeviceNet The above Plasma power source includes (Intelligent Gas Control) with flow control RCI² analog interface prepared for digital communication incl. 6 m cable EtherCAT Hardwire multi – digital/analog I/O Double CAN plug incl. CAN distributor box Remote control plug incl. Arc Detect signal Built-in water flow control Interface The RCI² is connected to the welding machine via...

Open the catalog to page 7

Migatronic DATA We reserve the right to make changes. PLASMA PI 500 ROBO DC w / PI 500 ROBO AC/DC w Mains current, effective, A Open circuit voltage, V Application class Protection class Maks 20°C MIG, A/% Maks 20°C TIG, A/% Maks 20°C PLASMA, A/% Duty cycle cooling unit PI 500 ROBO DC w / PI 500 ROBO AC/DC w Cooling capacity (1 l/min.), W WELDING VALUE Dealer stamp:

Open the catalog to page 8All Migatronic Welding Equipment LTD. catalogs and technical brochures

-

SIGMA SELECT

8 Pages

-

CALL ME COWELDER

20 Pages

-

AUTOMIG 300 PULSE

4 Pages

-

Robot integration

12 Pages

-

Call Me CoWelder

4 Pages

-

Automig 183

2 Pages

-

FOCUS TIG 160 DC HP PFC

2 Pages

-

Sigma Galaxy

8 Pages

-

Sigma²

8 Pages

-

Omega²

4 Pages

-

Automig² I

4 Pages

-

Omega Mini

2 Pages

-

AUTOMIG

2 Pages

-

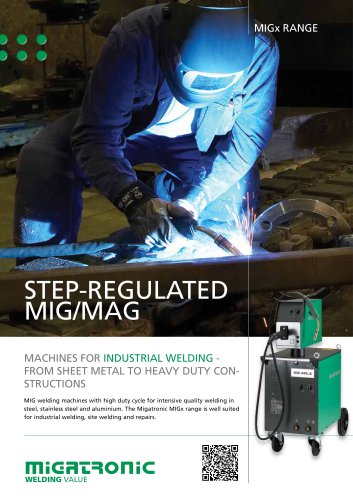

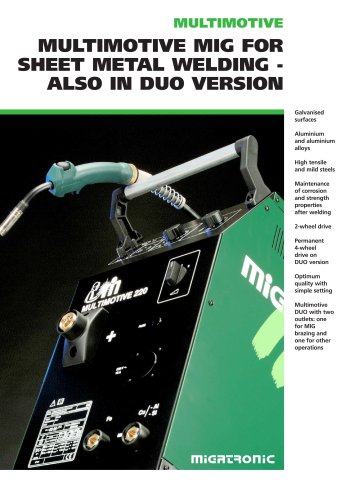

MIG

2 Pages

-

Focus Stick 120E

2 Pages

-

Focus MIG130

2 Pages

-

Focus Stick 160 E PFC

2 Pages

-

Focus TIG 200 AC/DC PFC

2 Pages

-

Focus TIG 200 DC PFC

2 Pages

-

OrderFocus TIG 160 DC PFC

2 Pages

-

Pi

12 Pages

-

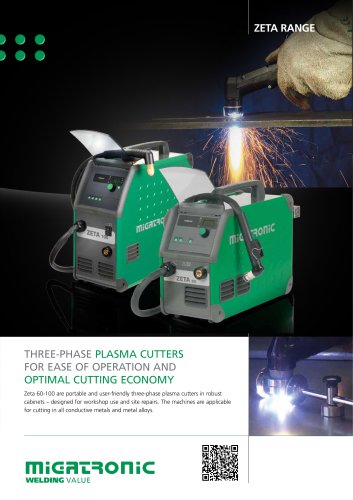

Zeta

2 Pages

-

Pi Plasma

3 Pages

-

MigaLOG

2 Pages

-

EN1090

4 Pages

-

welding torches

40 Pages

-

MIGATRONIC ACCESSORIES

27 Pages

-

RallyMIG 161i

2 Pages

-

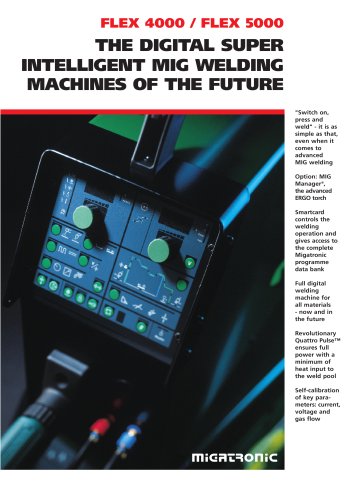

FLEX² 3000

3 Pages

-

Sigma² 300 | 400 | 500

12 Pages

-

TIG Torches

16 Pages

-

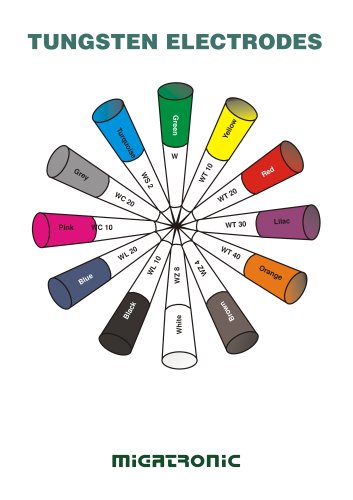

tungsten electrodes

34 Pages

-

Zeta Plasma cutters Series

2 Pages

-

MIG Series

2 Pages