Website:

MICROTRAC

Website:

MICROTRAC

Group: VERDER

Catalog excerpts

Particle size and shape characterization by Dynamic Image Analysis MICROTRRC PARTICLE CHARACTERIZATION dual camera technology

Open the catalog to page 1

Microtrac MRB - Particle Characterization at Its Best Comprehensive analysis of granules, powders and suspensions Microtrac MRB is your superior partner for the characterization of disperse systems. We provide our customers with advanced technologies to obtain consistently reliable results. Innovation and quality form the basis of our success. Microtrac MRB offers three product lines with competence centers on three continents: Scattered Light Analysis: Microtrac MRB is a leading supplier of laser diffraction systems (static light scattering), a versatile method for particle size...

Open the catalog to page 2

With the CAMSIZER X2 and CAMSIZER P4 Microtrac MRB sets standards in Dynamic Image Analysis. Thanks to the unique two-camera principle both instruments provide quick analyses with excellent accuracy and reproducibility over an extremely wide measuring range. This makes the CAMSIZERs ideally suited for routine analysis as well as quality control applications. Thanks to a powerful evaluation software which provides a multitude of valuable information and measurement parameters, the analyzers are also suitable for usage in R&D applications. The latest development, the CAMSIZER M1, measures...

Open the catalog to page 3

achieve a frame rate of more than 300 images per second which are evaluated in real time by a powerful software. Thus, the CAMSIZER X2 captures the images of hundreds of thousands to several millions of particles with highest accuracy within only 1 to 3 minutes. The CAMSIZER X2 provides a wide selection of particle information which allows for comprehensive and reliable characterization of the sample material. It is suitable for use in R&D as well as for routine tasks in quality control. Flexible Size and Shape Analysis for Highest Requirements The CAMSIZER X2 is a powerful, extremely...

Open the catalog to page 4

O Particle size and particle shape analysis from 0.8 um to 8 mm with Dynamic Image Analysis (ISO 13322-2) O Precise analysis of wide size distributions O Excellent resolution for narrow or multimodal size distributions O Detection of small amounts of oversized or undersized particles O Fully comparable to sieve analysis and laser diffraction results O A wealth of evaluation options (different size models, a variety of shape parameters, particle library, single frame evaluation, etc.) O Outstanding reproducibility O Measurement time 1 - 3 minutes, high sample throughput O Modular „X-Change“...

Open the catalog to page 5

Extremely Wide Measuring Range due to Dual Camera Technology MICROTRRC !*MEB Microtrac MRB’s unique dual camera technology is a landmark in the development of Dynamic Image Analysis. By simultaneously employing two cameras with different magnifications, extremely wide dynamic measuring ranges are archieved. This is accomplished without hardware adjustments or modifications and without compromising accuracy. Each camera is specialized for one measuring range. The ZOOM camera analyzes fine particles with highest precision whereas the BASIC camera detects the larger particles with excellent...

Open the catalog to page 6

DRY Measurement Principle Two cameras operate simultaneously during measurement: the BASIC camera (blue) analyzes the larger particles, the ZOOM camera (red) captures the small particles. This procedure ensures optimum measurement conditions for all particle sizes in a distribution.

Open the catalog to page 7

Ol Dispersion in liquids CAMSIZER X2 also offers the option to analyze particles in liquids with the X-Flow module. The suspension flows in a closed circle through a glass cell where the cameras record the particle images. The integrated ultrasonic unit further aids in the dispersion process. MICRQTRRC PVIEB Modular X-Change System for Maximum Flexibility Correct sample preparation and dispersion of the particles before passing into the measurement field are as important as the actual analysis. Particularly for fine powders which tend to agglomerate, sufficient dispersion is crucial to the...

Open the catalog to page 8

The CAMSIZER X2’s modular “X-Change” system offers three alternative Modular Design for Maximum Flexibility X-Jet Air pressure dispersion X-Dry dispersion options, permitting the selection of the optimum method for each sample type. The user may choose between wet dispersion with X-Flow X-Fall or dry measurement either in free fall with X-Fall or in an air flow with X-Jet. The modules and cartridges are quickly and easily exchanged which makes Wet measurement working with the CAMSIZER X2 convenient and safe. Gravity dispersion Air Pressure Dispersion with X-Jet Feed chute Many materials...

Open the catalog to page 10

Wet Measurement with X-Flow Measuring range LEDs Liquid level ensor s The wet module X-Flow analyzes suspensions in a size range from 0.8 µm to 1 mm. Flow cell The sample moves within a closed loop from the dispersion bath to the flow cell where the camera system captures the particle images. X-Flow comes with an ultrasonic bath and strong centrifugal pump to ensure efficient dispersion. Dispersion bath Basic Camera Suitable dispersion media are water, alcohol, and also nonpolar organic solvents. Analysis of suspensions Effective dispersion with ultrasound Resistant to organic solvents...

Open the catalog to page 11

A Wealth of Analysis and Evaluation Options All parameters at a glance: Dynamic Image Analysis provides comprehensive information about the sample material to be analyzed. The high-performance CAMSIZER software measures dozens of parameters from every single particle and presents the results in a clearly structured, standard-compliant measurement report. Functions like the comprehensive export option and the generation of synoptical tables or trend analyses are routine procedures. Storage and automatic monitoring of predetermined product specifications are also part of the software....

Open the catalog to page 12

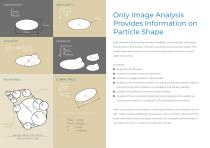

ASPECT RATIO χc min χFe max χc min χFe max SYMMETRY Bulk material properties like density, flowability, compactibility, conveying characteristics and surface condition are influenced by particle shape. This Areal Aconvex makes these parameters a crucial process and quality indicator in many Only Image Analysis Provides Information on Particle Shape application areas. Examples: n Angularity of abrasives n Analysis of broken fractions in granules n Analysis of the roundness of plastic or metal powder particles for Additive Manufacturing (direct influence on flowability and packing density) n...

Open the catalog to page 13All MICROTRAC catalogs and technical brochures

-

MICROTRAC - MRB

8 Pages

-

belcat II

8 Pages