Website:

MICROTEM

Website:

MICROTEM

Catalog excerpts

production program

Open the catalog to page 1

Company, Mission & Vision Mechanical Seals 6 • What is a mechanical seal? 7 • Dual seals configuration 10 • Conversion tables, coding, table of codes 11 Propeller shaft seals 58

Open the catalog to page 5

company mission & vision

Open the catalog to page 6

COMPANY Microtem is an Italian company specialized in the design and construction of mechanical seals and sealing systems for pumps, compressors, turbines, agitators and marine propulsion systems. Founded in 2005, it immediately stood out for its ability to innovate, designing original and highly reliable mechanical sealing systems. In addition to the standard production, Microtem has specialized in the development of ‘custom’ mechanical seals, by offering a precise design service and ever-present aftersales assistance. Today we are the point of reference for manufacturers of pumps,...

Open the catalog to page 7

mechanical seals

Open the catalog to page 8

WHAT IS A MECHANICAL SEAL? The mechanical seal is a dynamic device which, installed in a rotary machine, has the task of preventing the process fluid from being dispersed or coming into contact with the surrounding environment. Typically, this device has a rotating part connected to the drive shaft and a stationary part fastened to the machine where a seal needs to be created. To carry out this action, the rotating face, dragged by the propulsion, slides frontally against the stationary part, creating a barrier capable of operating for tens of thousands of hours. Its design depends on the...

Open the catalog to page 9

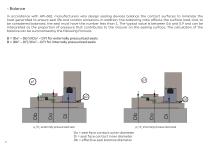

- Balance In accordance with API-682, manufacturers who design sealing devices balance the contact surfaces to minimize the heat generated to ensure seal life and contain emissions. In addition, the balancing ratio affects the surface load, and, to be considered balanced, the seal must have this number less than 1. The typical value is between 0.6 and 0.9 and can be interpreted as the proportion of pressure that contributes to the ‘closure’ on the sealing surface. The calculation of the balance can be summarised by the following formula: B = (Do2 – Db2)/(Do2 – Di2) for externally...

Open the catalog to page 10

- Internal or external mechanical seal The internal seal is completely submerged in the process fluid. The external configuration places the mechanical seal in contact with the atmosphere. It is easy to understand that an internal mechanical seal cannot be positioned externally and vice versa, since, otherwise, the contact faces would tend to open due to the pressures

Open the catalog to page 11

DUAL SEAL CONFIGURATIONS - Double opposite mechanical seal (back-to-back) This configuration type is often adopted when there is a need to guarantee “zero leakage”. The internal single mechanical seals are positioned back to back, with an additional pressurized chamber filled with fluid to prevent the secondary seal from dry-running. - Dual tandem mechanical seal It consists of two sets of seals mounted in series, with a liquid buffer (inlet/outlet) maintained at atmospheric pressure. This configuration is used in petrochemical plants and refineries and is not suitable for toxic or abrasive...

Open the catalog to page 12

MICROTEM CODE MATERIAL OF SEAT MATERIAL OF FLEXIBLE ELEMENTS + MATERIAL OF SPRINGS ■<MATERIAL OF OTHER COMPONENTS + TABLE OF CODES d = Shaft diameter [mm] p1 = Average pressure [bar] p2 = Atmospheric pressure [bar] p3 = Buffer fluid pressure [bar] Ap = (p1-p2); (p3-p1); (p3-p2) [bar] T = Operating temperature [°C] vg = Sliding speed [m/s]

Open the catalog to page 13

tyMSSM industrial sector

Open the catalog to page 14

MECHANICAL SEALS Components Seals / Industrial Sector Standard face materials d = from 10 mm up to 140 mm * px = from 0.5 bar up to 16 bar T = from -50°C up to +180°C vg = 15 m/s Axial movement: +/-1 mm * Also available in inches Stationary rings Part list Applications Conical spring, unbalanced, dependent on the direction of rotation, utilized for general services machinery at low and medium pressure; It can be also manufactured in accordance with UNI EN 12756 (ex DIN 24960) standard and is available in different materials. Thanks to many different stationary rings, the mechanical seal can...

Open the catalog to page 16

MECHANICAL SEALS Components Seals / Industrial Sector Standard face materials d = from 10 mm up to 40 mm * px = from 0.5 bar up to 16 bar T = from -50°C up to +180°C vg = 15 m/s Axial movement : +/-1 mm * Also available in inches Stationary rings Part list Applications Conical spring, unbalanced, dependent on direction of rotation, utilized for general services machinery at low and medium pressure; It can be also manufactured in accordance to UNI EN 12756 (ex DIN 24960) standard, and is available in different materials. Thanks to many different stationary rings, the mechanical seal can be...

Open the catalog to page 17

MECHANICAL SEALS Components Seals / Industrial Sector Standard face materials d = from 25 mm up to 160 mm * px = from 0.5 up to 10 bar T = from -50°C up to +180°C vg = 10 m/s Axial movement: +/-1 mm * Also available in inches Seal drawing with stationary ring configuration S0 Part list Applications Cylindrical spring mechanical seal, unbalanced, dependent on the direction of rotation, designed in different solutions, is widely used in the refinery and petrochemical industry. It is available in different materials. Rotary face: AISI304 (J) AISI316 (J1) resin/antimony carbon (G2/G3) silicon...

Open the catalog to page 18

MECHANICAL SEALS Components Seals / Industrial Sector mrm40 Operative Limits d = from 14 mm up to 100 mm * px = from 0.5 bar up to 12 bar T = from -40°C up to +180°C vg = 15 m/s Axial movement: +/-0,5 mm * Also available in inches Stationary ringsDescription Cylindrical spring mechanical seal, unbalanced, independent of direction of rotation, provided with elastomeric bellows, is suitable for general services machinery at low and medium pressure. It is available in different materials. The stationary rings are available both with cuff or O-ring. Seal drawing with stationary ring...

Open the catalog to page 19

(c MICROTEM MECHANICAL SEALS Components Seals / Industrial Sector Standard face materials Elastomers mrm51 Operative Limits Description d = from 14 mm up to 100 mm * px = from 1 bar up to 16 bar T = from -40°C up to +180°C vg = 10 m/s Axial movement: +/-2 mm * Also available in inches J5LML Seal drawing with stationary ring configuration S10 Part list Applications Unbalanced M.S., with elastomeric bellows and high axial misalignment compensation capacity, provides a wide range of configurations. Also recommended in dual applications, it is made according to UNI EN 12756 (ex DIN 24960). The...

Open the catalog to page 20All MICROTEM catalogs and technical brochures

-

Company profile

12 Pages