Catalog excerpts

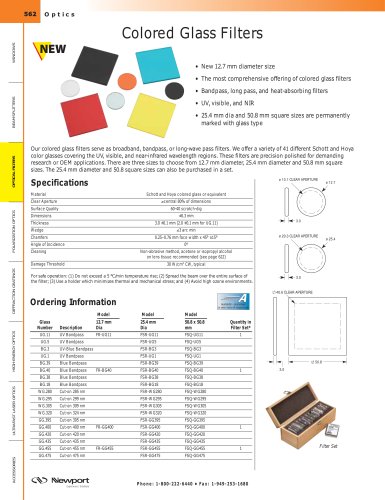

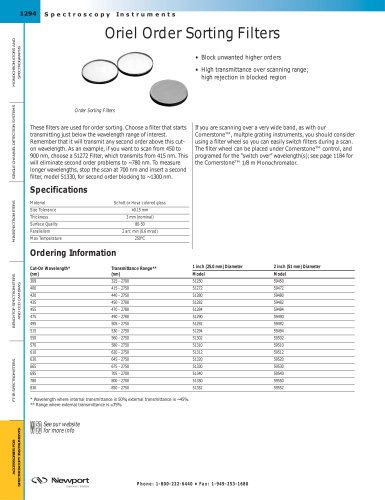

779 Email: sales@newport.com • Web: newport.com M o t o r i z e d P o s i t i o n i n g TECHNICAL REFERENCE MOTORIZED LINEAR STAGES MOTORIZED ROTATION STAGES MOTORIZED OPTICAL MOUNTS MOTORIZED ACTUATORS CONTROLLERS AND AMPLIFIERS SYSTEMS XM Series Ultra-Precision Linear Motor Stages • Non-contact, direct-drive system ensures ultraprecision motion with high dynamics and reliability • Sub-nm, high precision glass scale encoder provides accurate position feedback with 80 nm repeatability • Extra-large, ironless, high-efficiency linear motor minimizes heat generation • Ultra-quiet anti-creep crossed roller bearings assure ripple-free motion without cage migration The XM is the ultimate solution for the most demanding manufacturing and test and measurement applications. It meets ultra-precision motion requirements with high dynamics and reliability for 24/7 production environments. Typical applications include semiconductor wafer inspection, sensor test and calibration, laser machining and ultra-precision assembly. Unlike screw driven stages, the XM employs a center-driven, ironless linear motor as the driving element. Since the linear motor is a frictionless direct drive device, there is no backlash or hysteresis, wind-up or stiction limiting the motion performance. The linear motor drive also offers the advantage of higher speed, acceleration and system responsiveness with no wear to motor brushes or drive screws. The extra-large, ironless motor coil ensures zero cogging for ultra smooth velocity control and provides higher efficiency compared to alternative stage designs. This results in significantly less heat generation, which is generally the main limit for ultra-precision motion applications. To further improve thermal management and its effect on stage performance, the XM also has the benefit of a sophisticated length decoupling of the magnetic track from the stage carriage. XM stages are machined from stress-relieved 7075 aluminum, ensuring long-term strength and stability. All critical stage surfaces undergo multiple machining processes and precision grinding under strict temperature and quality control to further improve overall performance and accuracy. The T-shaped carriage used on the XM provides the optimum solution for precision XY assemblies without impacting the stage preload. It also more robust and is more tolerant to non-ideal mounting conditions than stages with a C-shaped carriage design. To ensure the most accurate trajectory control, XM stages feature best-in-class matched pairs of anti-creep crossed roller bearings. The absence of recirculating elements in the XM leads to outstanding ripple-free motion adequate for the most demanding scanning and inspection systems. Moreover, the geared retainers on these bearings prevent bearing cage migration, which can occur with other linear bearings. Precision position feedback is supplied by a high accuracy LIF 481 Heidenhain Linear Scale. The precision alignment and mounting of this low thermal expansion scale in the center of the stage minimizes the impact of temperature changes on stage repeatability and accuracy. The encoder signals are interpolated by Newport’s XPS motion controller with sub-nm Accuracy of an XMS50 stage with linear error compensation and positioner mapping. The data was taken one day after the calibration and at different positions. The plot shows error readings over five cycles of back and forth motion. The accuracy is 0.3 ìm p-p. XM stages are capable of performing very small incremental steps with high accuracy and stability suitable for the most demanding test and assembly applications. resolution and less than 10 nm noise for outstanding position sensitivity and stability. Absolute home position and limit signals are incorporated on the same scale without any further electronics or mechanics for improved reliability and accuracy. In general, all electronics are attached to the stationary base, so there are no moving cables inside the stage. This results in an extremely compact design with exceptional reliability and safety. Need Accuracy to 1 ìm? Contact Newport to learn about our micropositioning calibration services needed for critical positioning applications. Upon request, we will create, implement and verify an electronic compensation routine to improve the absolute position accuracy of XM stages to 1 ìm/100mm when used with our XPS advanced motion control system. A certificate of calibration along with measured error maps is included. Interferometer Current Position Stage Setpoint Position 0 Time (s) Position (nm) 0.5 1 1.5 2 2.5 3 3.5 4 0 50 100

Open the catalog to page 1

780 Phone: 1-800-222-6440 • Fax: 1-949-253-1680 M o t o r i z e d P o s i t i o n i n g MOTORIZED ROTATION MOTORIZED LINEAR STAGES TECHNICAL REFERENCE STAGES SYSTEMS CONTROLLERS AND AMPLIFIERS MOTORIZED ACTUATORS MOTORIZED OPTICAL MOUNTS Position (mm) Straightness (ìm) -1.5 -1 -0.5 0 0.5 1 1.5 -25 -15 -5 5 15 25 XM stages deliver ripple-free motion as required by many precision scanning and wafer inspection processes. Shown is the straightness of an XMS50 during one forward and return cycle, measured with an interferometer. 0 Position (mm) 99.80 Speed (mm/s) 4 8 12 16 20 24 28 32 36 40 44...

Open the catalog to page 2

M o t o r i z e d P o s i t i o n i n g 781 Email: sales@newport.com • Web: newport.com TECHNICAL REFERENCE MOTORIZED LINEAR STAGES MOTORIZED ROTATION STAGES MOTORIZED OPTICAL MOUNTS MOTORIZED ACTUATORS CONTROLLERS AND AMPLIFIERS SYSTEMS A typical assembly using XML210, XMS50 and GTS30V Ordering Information Model Description XMS50 XMS linear motor stage, 50mm travel XMS100 XMS linear motor stage, 100mm travel XMS160 XMS linear motor stage, 160mm travel XML210 XML linear motor stage, 210mm travel XML350 XML linear motor stage, 350mm travel Recommended Motion Controller: XPS (see page 844) A1...

Open the catalog to page 3All MICRO-CONTROLE / Spectra-Physics catalogs and technical brochures

-

Precision Motion Control

27 Pages

-

OPTICAL FIBER ALIGNMENT

6 Pages

-

SA2_90028936F

1 Pages

-

10BPF10-370_ROHS

1 Pages

-

10BPF10-320_ROHS

1 Pages

-

10BPF10-310

1 Pages

-

M-401

1 Pages

-

Tunable Diode Lasers

16 Pages

-

Custom Component Solutions

6 Pages

-

Vision IsoStation Brochure

5 Pages

-

Nanopositioning Solutions

55 Pages

-

newport ressource

1640 Pages

-

Motion PL30

24 Pages

-

CONEX-AG-LS25-27P

2 Pages

-

Nanopositioners

40 Pages

-

Prisms and retroreflectors

9 Pages

-

Beamsplitters

34 Pages

-

Spherical and aspherical lenses

35 Pages

-

Optrical mirror

33 Pages

-

Systems Solutions brochure

6 Pages

-

Fast Steering Mirrors

4 Pages

-

Optical Delay Line Kit

1 Pages

-

Long Scan Autocorrelator

1 Pages

-

I-V Test Station

2 Pages

-

Projects in Optics

2 Pages

-

Projects in Interferometry

2 Pages

-

Azimuth / Elevation Gimbals

2 Pages

-

Air-Bearing System

2 Pages

-

X-Ray Diffractometer

2 Pages

-

Motion System

2 Pages

-

Pick & Place Machine

2 Pages

-

Metrology Positioning System

2 Pages

-

I-500 Series Pneumatic Isolators

1 Pages

-

LabLegs™ Upgrade Kits

1 Pages

-

UCS Series Cleanroom Tables

1 Pages

-

TE Series Table Enclosures

1 Pages

-

LTE Series Light Tight Enclosure

1 Pages

-

Oriel Integrating Spheres

5 Pages

-

Oriel Inspection Probes

1 Pages

-

Oriel Flanged Sample Compartment

1 Pages

-

Oriel Focusing Lens Assembly

2 Pages

-

Xenon Flashlamps

2 Pages

-

Oriel InstaSpec X CCD

3 Pages

-

Oriel Mini Monochromator

3 Pages

-

Oriel 77200 1/4 m Monochromator

3 Pages

-

OSM2 Series Spectrometers

2 Pages

-

Oriel Optical Choppers

2 Pages

-

Electronic Safety Shutters

1 Pages

-

Oriel Optical Shutter

1 Pages

-

Iris Diaphragms

1 Pages

-

Beam Apertures for Light Sources

1 Pages

-

Adaptor Washers, Screw Sets

1 Pages

-

Mounting Bridles

1 Pages

-

Adaptors and Retaining Rings

1 Pages

-

Opto-Mechanical Components Set 2

1 Pages

-

Opto-Mechanical Components Set 1

1 Pages

-

X26 Series Mirror Mount

1 Pages

-

Mini Optical Rails and Carriers

2 Pages

-

Slotted Bases

2 Pages

-

SDS Series Angle Brackets

1 Pages

-

Rotation Adaptor

1 Pages

-

PBN Series Base Plates

1 Pages

-

Mounting Plates and Platforms

1 Pages

-

Modular Riser Plates

1 Pages

-

Magnetic Bases

2 Pages

-

Kinematic Stops and Nudgers

1 Pages

-

Kinematic Bases

2 Pages

-

Fixed Height Platforms

1 Pages

-

EQ Series Angle Brackets

2 Pages

-

Base Clamps

1 Pages

-

360 Series Angle Brackets

1 Pages

-

VALUMAX® Posts and Post Holders

1 Pages

-

Rod Platforms

1 Pages

-

Rod Clamps

1 Pages

-

Posts and Post Holders

3 Pages

-

Post Clamps and Accessories

1 Pages

-

Pedestal-Base Post Holders

2 Pages

-

Modular Construction System

1 Pages

-

Holders for Pedestal Posts

1 Pages

-

Heavy Duty Rod Systems

2 Pages

-

Dual Rod Systems

1 Pages

-

Breadboard Support Posts

1 Pages

-

Pedestal Post System

2 Pages

-

VersaStar™ Modular Filter Wheel

1 Pages

-

Motorized Filter Wheels

1 Pages

-

Manual Filter Wheels

1 Pages

-

Indexed Filter Wheel Mounts

1 Pages

-

Filter Holders

1 Pages

-

Filter and Optic Holders

1 Pages

-

V-Blocks

1 Pages

-

Precision Beam Steerers

1 Pages

-

Polarizer Rotation Mounts

1 Pages

-

Pockels Cell Positioner

1 Pages

-

Kin-a-Flip Mount

1 Pages

-

Diffraction Grating Mount

2 Pages

-

Cube Beamsplitter Holders

1 Pages

-

Beam Steerers

1 Pages

-

Aegis Qube™ Beam Routing System

5 Pages

-

Variable Lens Holder

1 Pages

-

Self-Centering Lens Mounts

1 Pages

-

Precision XY Optic Positioners

1 Pages

-

Multi-Axis Lens Positioners

4 Pages

-

Lens Focusing Mount

1 Pages

-

Fixed Lens Mounts

1 Pages

-

Cylindrical Lens Holders

1 Pages

-

Compact Lens Positioners

1 Pages

-

Adjustable Lens Mounts

1 Pages

-

UV Objective Lenses

1 Pages

-

Reflective Microscope Objectives

2 Pages

-

Precision Objective Lenses

1 Pages

-

Objective Lenses

1 Pages

-

Laser Diode Objective Lenses

1 Pages

-

Ultrafast Laser Chirped Mirrors

2 Pages

-

Ultrafast Laser Beam Sampler

1 Pages

-

Broadband Hollow Retroreflectors

1 Pages

-

Volume Bragg Gratings™

1 Pages

-

Plane Ruled Reflection Gratings

2 Pages

-

Pellicle Beamsplitters

1 Pages

-

Broadband Beam Samplers

1 Pages

-

Zero-Order Quartz Wave Plates

1 Pages

-

Zero-Order Precision Wave Plates

1 Pages

-

Precision Linear Polarizers

1 Pages

-

Polarcor™ Linear Polarizers

1 Pages

-

Glan-Laser Calcite Polarizers

1 Pages

-

Glan-Thompson Calcite Polarizers

1 Pages

-

Broadband Polarization Rotators

1 Pages

-

Infrared Lenses

1 Pages

-

BK 7 Precision Bi-Convex Lenses

2 Pages

-

BK 7 Precision Bi-Concave Lenses

1 Pages

-

Molded Glass Aspheric Lenses

3 Pages

-

Aspheric Condenser Lenses

1 Pages

-

Spherical Ball Micro Lenses

1 Pages

-

Precision Cylindrical Lens Sets

1 Pages

-

Gradient Index Micro Lenses

2 Pages

-

Three-Axis Spatial Filters

2 Pages

-

Precision Singlet Lens Sets

3 Pages

-

OptiSet™ Optics Sets

2 Pages

-

Laser Collimator

1 Pages

-

Laser Beam Expanders

2 Pages

-

High-Energy Pinhole Apertures

1 Pages

-

High-Energy Variable Attenuators

3 Pages

-

High-Energy Laser Beam Expanders

2 Pages

-

Electronic Shutter System

1 Pages

-

Compensated Attenuators

1 Pages

-

UV Beam Viewer

1 Pages

-

Shear Plate Collimation Tester

1 Pages

-

Sapphire Windows

1 Pages

-

Interferometer Flats

1 Pages

-

High-Energy Laser Wedged Windows

1 Pages

-

Parallel Windows

1 Pages

-

Light Pipe Homogenizer

1 Pages

-

VALUMAX® Right-Angle Prisms

1 Pages

-

Precision Right-Angle Prisms

1 Pages

-

VALUMAX® Broadband Mirrors

2 Pages

-

Ultra-Low Loss SuperMirrors™

2 Pages

-

Laser Line Dielectric Mirrors

2 Pages

-

High-Energy Nd:YAG Laser Mirrors

2 Pages

-

Broadband SuperMirrors™

1 Pages

-

Broadband Metallic Mirrors

2 Pages

-

Broadband Dielectric Mirrors

2 Pages

-

Oriel TE Cooler Controller

1 Pages

-

Oriel Laboratory Power Supply

1 Pages

-

Oriel Current Preamplifier

1 Pages

-

Micro-Beam Profiler

1 Pages

-

Laser Beam Profiler

2 Pages

-

High-Speed Photodetectors, GHz

7 Pages

-

Oriel Silicon Detectors

2 Pages

-

Oriel Pb and PbSe Detectors

2 Pages

-

Oriel InGaAs and Ge Detectors

2 Pages

-

Oriel Photomultiplier Tubes

2 Pages

-

Fiber Optic Detectors

2 Pages

-

PulseScout Autocorrelator

2 Pages

-

Heat Control Filters

1 Pages

-

Colored Glass Filters

3 Pages

-

Bandpass Filters

4 Pages

-

Laser Line Filters

2 Pages

-

Infrared Neutral Density Filters

1 Pages

-

Short and Long-Wave Pass Filters

2 Pages

-

Oriel Order Sorting Filters

1 Pages

-

UZ Series Vertical Linear Stages

2 Pages

-

HXP100 Hexapod

2 Pages

-

BG Series Goniometric Cradles

4 Pages

-

EL/EN Series Lab Jacks

1 Pages

-

ECN/ECR Series Lab Jacks

2 Pages

-

Single-Mode Fiber Couplers

1 Pages

-

Multimode Fiber Couplers

2 Pages

-

GRIN Lens Fiber Couplers

1 Pages

-

Fiber Optic Positioners

3 Pages

-

466A Series XYZ Flexure Stages

1 Pages

-

BM Series Micrometers

2 Pages

-

Apex Fiber Illuminators

2 Pages

-

Series Q Deuterium Sources

1 Pages

-

Deuterium Lamp Power Supplies

1 Pages

-

Deuterium Lamps

2 Pages

-

Apex Deuterium Lamp Sources

1 Pages

-

Spacer Tubes for Light Sources

1 Pages

-

Oriel Ozone Eater

1 Pages

-

Ozone Blowers

1 Pages

-

Flange Mounted Cells

1 Pages

-

Beam Turning Assemblies

2 Pages

-

Aspherab Lens Assemblies

2 Pages

-

Mounts for Beam Probes

1 Pages

-

Liquid Filters for Light Sources

1 Pages

-

Input Hood for Light Sources

1 Pages

-

Holders for Oriel Single Fibers

2 Pages

-

Flanged Mounts for Fiber Bundles

1 Pages

-

Filter Holder for Beam Probes

1 Pages

-

Coupling Rings for Light Sources

1 Pages

-

Flood Exposure Sources

6 Pages

-

Mask Alignment Tools

4 Pages

-

Reference Solar Cell and Meter

1 Pages

-

Class A Solar Simulators

3 Pages

-

150 - 300 W Solar Simulators

2 Pages

-

150 W Low Cost Solar Simulator

2 Pages

-

Apex Monochromator Illuminators

4 Pages

-

Quartz Tungsten Halogen Lamps

3 Pages

-

Blackbodies

2 Pages

-

Apex Infrared Light Sources

2 Pages

-

Xenon Flashlamp Systems

2 Pages

-

Uniform Illuminators

3 Pages

-

Simplicity Series Arc Sources

2 Pages

-

Series Q Lamp Housings

4 Pages

-

Series Q Arc Lamp Sources

2 Pages

-

Silicon Carbide Light Source

1 Pages

-

Oriel PhotoMax Lamp Housing

3 Pages

-

Fading Test System

1 Pages

-

Digital Arc Lamp Power Supplies

2 Pages

-

Modular Infrared Light Sources

2 Pages

-

DC Short Arc Lamps

3 Pages

-

1600 W Research Arc Lamp Sources

1 Pages

-

Research Arc Lamp Housings

3 Pages

-

Apex Arc Lamp Sources

2 Pages

-

Calibrated Sources and Services

2 Pages

-

Pencil Style Calibration Lamps

3 Pages

-

Laser Diode Adaptors

1 Pages

-

Cylindrical Laser Mounts

1 Pages

-

Laser Diode Drivers, 500B Series

2 Pages

-

TEC Controller, 300B Series

2 Pages

-

VBG Raman Laser Modules

2 Pages

-

Laser Diode Modules, LQN Series

2 Pages

-

Alignment Laser

1 Pages

-

Ultraviolet Safety Equipment

1 Pages

-

Laser Safety Glasses and Goggles

4 Pages

-

Laser Safety Windows

1 Pages

-

Infrared IR Viewer

1 Pages

-

177 Air-Cooled Ion Lasers

2 Pages

-

Beam Dump

1 Pages

-

Empower ® Q-Switched Laser

2 Pages

-

V-Xtreme™ Q-Switched Laser

2 Pages

-

Fiber Pigtailed Laser Diode

1 Pages

-

488 nm CW Laser- Cyan™ OEM

2 Pages

-

CW Lasers- Excelsior® OEM

4 Pages

-

Inspire™ OPO Family

2 Pages

-

Polarization Controller, Manual

2 Pages

-

Fiber Optic In-Line Polarizers

1 Pages

-

Fiber Optic Depolarizers

1 Pages

-

Mode Scrambler

1 Pages

-

Index-Matching Fluid

1 Pages

-

Fiber Optic Scribes

1 Pages

-

Fiber Jacket Stripper

1 Pages

-

Variable Ratio Couplers

2 Pages

-

Fixed Fiber Optic Attenuator

1 Pages

-

Fiber Optic Switches

2 Pages

-

Kevlar® Shears

1 Pages

-

Fiber Preparation Kit

1 Pages

-

Fiber Optic Splice

1 Pages

-

Benchtop Couplers and WDMs

1 Pages

-

Fiber Coating Stripper

1 Pages

-

Electronic Fiber Cleavers

1 Pages

-

Fiber Optic Isolator

2 Pages

-

Fiber Pigtailed Collimator

1 Pages

-

Fiber Optic Collimators

2 Pages

-

Photonic Crystal Fibers

4 Pages

-

Oriel Multi-track Fiber Bundles

2 Pages

-

Communication Grade Fibers

1 Pages

-

Infrared Fibers

1 Pages

-

Single Branch Fiber Bundles

1 Pages

-

Multi-Branch Fiber Optic Bundles

1 Pages

-

Power Delivery Fibers

1 Pages

-

Liquid Light Guides

2 Pages