Catalog excerpts

Innovative Braking and Controls Worldwide Multiple Disc Brakes posi-torque winch brakes, pressure override brakes, wheel mount brakes, and driveline brakes Spring Apply Hydraulic Release Multiple Disc Brakes MICO, Inc.

Open the catalog to page 1

Why choose MICO? MICO, Inc. designs, manufactures and markets hydraulic components, controls, and brake systems primarily for off-road markets. We have manufacturing facilities in: North Mankato, Minnesota U.S.A. Ontario, California U.S.A. Empalme, Sonora, Mexico Many of the world’s largest off-highway OEMs value the knowledgeable staff at MICO and work with us to make their products better. Our custom-engineered products are designed with the customer requirements as the primary driver. It is our intent to help customers build their systems with our expertise in hydraulic components,...

Open the catalog to page 2

Swing Drive Equipment Forestry Equipment Agricultural Equipment Heavy Construction Equipment Mining Equipment In-Plant & Warehouse Equipment Airport Support Vehicles MICO, Inc.

Open the catalog to page 3

Representation and Service In addition to the numerous design improvements over competitive models, you also get MICO representation and service which is second to none. Direct Access to MICO Engineers Involving the customer directly in product design and testing ensures that customer requirements are met. Our engineering staff has a very strong background in spring apply, hydraulically released brakes. As new technology becomes available, it is integrated into MICO products and when technology is not available, MICO Engineers develop it. Simplied Disassembly and Assembly Features such as...

Open the catalog to page 4

Multiple Disc Brakes (spring apply, hydraulic release) MICO engineers are innovators in the design of spring apply, hydraulic release multiple disc brakes, wheel brakes, closed-output motor brakes, posi-torque winch brakes and more. The engineers are committed to improving the product while reducing cost. Simple, straight forward designs result in rugged brake products. These products require less maintenance because they are designed with fewer moving parts. They are truly superior in reliability and performance. construction, material handling, agriculture, mining, sanitation, utilities...

Open the catalog to page 5

Catalog Code Explanation The catalog code numbering system allows you to construct the brake by combining the variables that meet your needs. Catalog code number example: 3A-060618-M. A production number will be assigned by our Engineering Department upon receipt of your order. Production order number example: 13-538-004. NOTE For brake combinations that are not currently established, but possible, quotation and assignment of part number must be predicated by receipt, review, and acceptance of applicable multiple disc brake data sheet. Options Explanation Z = OIL COOLED OPTION, designated...

Open the catalog to page 6

General Brake Information 1. Brake torque values listed are dry static torque ratings except for the C-Mount Posi-Torque Brakes (page 26), Compact Wheel Mount Brakes (page 36), and Driveline Multiple Disc Brakes (pages 40-45). a. For brakes with Z option (oil-cooled) actual torque is 67% of the dry torque listed. b. Static torque may vary ± 10% from specied values. 2. Initial release pressure is the point where the amount of hydraulic pressure to relieve the spring force on the rotor stack has zero brake torque with no running clearance. 3. Full release pressure is the amount of hydraulic...

Open the catalog to page 7

Multiple Disc Brakes Modular Design Cover, Spring Plate and Pressure Plate constructed of heavy duty ductile iron. Features Large diameter spline shafts virtually eliminate spline battering Versatile modular design Spring loaded, hydraulically released Sealed environment - isolation from contaminants Nitrile case seals High strength ductile iron construction Standard SAE mounting anges Powerful Chrome Silicon Die Springs automatically apply the brake's disc packs when hydraulic pressure drops. Benets Eliminates problems found in competitive brake designs, such as piston breakage, piston...

Open the catalog to page 8

Increased Bearing Support improves shaft alignment between motor, brake and driven load. Spline Shafts are constructed of high quality, heat treated 8620 steel for high strength and long life. Larger pitch diameter splines for shaft to disc interface give, in many cases, a seven to one advantage in strength. Improved lower tooth loading helps to eliminate spline battering. Inboard Oil Seal allows for gear box lubrication of the bearing. Friction Discs use sintered metallic linings and 1035-1050 steel core material for long life. Large disc diameters are possible because the balanced piston...

Open the catalog to page 9

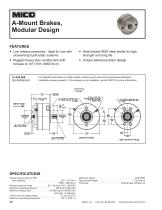

A-Mount Brakes, Modular Design FEATURES Low release pressures - ideal for use with closed-loop hydrostatic systems Heat treated 8620 steel shafts for high strength and long life Rugged heavy-duty construction with torques to 1017 N·m (9000 lb·in) Unique balanced piston design For detailed information on other model numbers go to www.mico.com/service-literature/ installation-drawing-search. If the drawing is not available, contact MICO for more information. millimeters inches OUTPUT FACE SPECIFICATIONS Torque range at 0 bar (0 PSI) back pressure . . . . . . . . . . . . . . . . . . . . . . ....

Open the catalog to page 10

CATALOG CODE (See NOTE on the top of page 6) Not all of the brake combinations are possible due to certain design limitations. NOTE: Dry design only, not for wet applications. OUTPUT FACE (Available separately or in combination) D - Double Bearing S - Speed Sensor OUTPUT SPLINE / INPUT SPLINE 06/06 10/10 14/14 25/25 INPUT FACE SAE Designation 06 = 25.4 mm (1.00 in) Diameter 6B 10 = 25.4 mm (1.00 In) Diameter Keyed 14 = 14T 12/24 25 = 31.8 mm (1.25 in) Diameter Keyed For other congurations, consult a MICO Applications Specialist. CATALOG CODE MODEL NUMBER Initial Release Pressure bar (PSI)...

Open the catalog to page 11

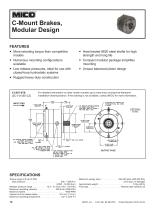

C-Mount Brakes, Modular Design FEATURES More retarding torque than competitive models Heat treated 8620 steel shafts for high strength and long life Numerous mounting congurations available Compact modular package simplies mounting Low release pressures, ideal for use with closed-loop hydrostatic systems Unique balanced piston design Rugged heavy-duty construction For detailed information on other model numbers go to www.mico.com/service-literature/ installation-drawing-search. If the drawing is not available, contact MICO for more information. INPUT END millimeters inches OUTPUT FACE...

Open the catalog to page 12All MICO catalogs and technical brochures

-

Brake Lock Application Guide

16 Pages

-

MICO Product Guide

20 Pages

-

Fluid Reservoirs

2 Pages

-

PRESSURE LIMITER

2 Pages

-

Hydraulic Brake Valves Catalog

64 Pages

-

Check Valve Assembly

2 Pages

-

Heavy-Duty Ratchet Handle

2 Pages

-

Wireless CAN

3 Pages

-

MICO CAN-bus Keypads

6 Pages

-

MOBEUS

4 Pages

-

CUSTOM ENGINEERED SWITCHES

48 Pages

-

Load-Apportioning Valve

2 Pages

-

Boosted Master Cylinders

27 Pages

-

Air/Hydraulic Actuators

22 Pages

-

Hydraulic Remote Actuators

27 Pages

-

Product Guide

20 Pages

-

MICO Boosted Master Cylinders

23 Pages

Archived catalogs

-

Caliper Disc Brakes Catalog

23 Pages

-

Electro-Hydraulic Components

15 Pages