Catalog excerpts

HYDROGEN BALL VALVES

Open the catalog to page 1

Ready In the future, hydrogen will make a significant contribution to sustainability and environmental protection. For example, in e-mobility as an alternative fuel in fuel cells or in the production of green steel. With years of experience in the gas sector, MHA ZENTGRAF has developed ball valves and flow control solutions for the complete hydrogen process chain: Hydrogen generation, transport and mobile pipelines as well as compression and dispenser stations. Pressure ratings up to 1000 bar are realized. Since 2020 MHA ZENTGRAF has been a member of the German Hydrogen and Fuel Cell...

Open the catalog to page 2

MHA ZENTGRAF Your sustainable partner Sustainability not only needs innovative products but also a sustainable partner. You can rely on MHA ZENTGRAF as your reliable supplier to build up a sustainable partnership. What makes MHA a sustainable partner? • 4 branch offices worldwide • RoHS und REACH compliant products • Customer support in all time zones • Recyclable packaging material • Lead free carbon steel • Raw materials from certified european sources Our ball valves are used in renewable energy and innovative systems like: Risk management • Wind turbines • Private owned company •...

Open the catalog to page 3

Key features of MHA ball valves in hydrogen applications Size reduction Metallic materials Ball valves have a significant ad- • Due to its high resistance against vantage compared to other types of Full flow cross section in open posi- used whenever possible. tion! A DN13 ½“ ball valve has a Cv • If higher material strength is required, value of 22 gal / min. This Cv value e.g. for stems, balls or trunnions, high can only be reached with sizes of strength austenitic stainless steels with approx. DN32 (1 ¼“) at other valve particular resistance to strain-induced types, e.g. globe or needle...

Open the catalog to page 4

The right product for your hydrogen application Hydrogen production, compression and storage Transportation e.g. category 3 and 4 containers (up to 650 bar @ +85 °C) Fuel station storage and compression Truck fueling 350 bar (500 bar storage) Car fueling 700 bar (1034 bar storage) Our products can be used in the complete hydrogen process chain - hydrogen generation, transport and mobile pipelines as well as compression and fueling stations. We also pay attention to your specific application conditions to offer you the technically and economically best solution.

Open the catalog to page 5

Hydrogen production H2 production This application includes systems e.g. for electrolysis or power-to-gas systems. Of course, ball valves from MHA ZENTGRAF can also be used at these lower pressure applications. Larger nominal widths of up to 4“ can also be offered to ensure maximum flow capacity. A leakage rate A according to DIN EN 12266 is guaranteed even at larger nominal diameters. Our valves are available with either threaded or flange connection according your specification. On request accessories like limit switches, locking devices or fully automated valves are available.

Open the catalog to page 6

Transport applications & fueling systems for hydrogen HFKH500 Transport and fueling up to 500 bar Gas transport and fueling applications set higher requirements for ball valves. At 350 bar fueling, system pressures up to 500 bar occur during compression and storage. Considering the temperature influence, a Type 3 Technology Cylinder for example is designed for system pressures of approximately 480 bar. During transport, vibrations and weather influences can put heavy strain on the system equipment. Additionally, valves for such kind of applications are actuated more frequently because...

Open the catalog to page 7

Transport & fueling systems for hydrogen HFKH650 Transport and storage up to 650 bar Higher compression of hydrogen during transport and storage improves the efficiency of the systems, saves installation space and, last but not least, reduces costs. Considering the temperature influence, State of the Art Type 4 Technology Cylinders are designed for pressures up to 650 bar. With the new HFKH650 ball valve, MHA offers a reliable solution for this kind of application. Additionally, it has a torque-optimized design so it can be conveniently switched by hand even at full differential pressure....

Open the catalog to page 8

Hydrogen dispenser stations HFKH1000 H2 fueling at pressures up to 1034 bar At 700 bar fueling of passenger cars, hydrogen is compressed and stored at pressures up to 1034 bar. Latest developments reveal a tendency to 700 bar technology also for commercial vehicles such as trucks and busses. ISO 19880-3 Standard (Gaseous Hydrogen – Fueling Stations – Part 3: Valves) differs between valves for maintenance (Class B) and operation (Class A) purpose. While Class B Valves are only meant to withstand 100 cycles of operation at room temperature, Class A Valves shall withstand 102000 cycles (100000...

Open the catalog to page 9

Block ball valve Stainless Steel AVAILABLE SIZES DIN ISO 228 Female thread, ANSI B1.20.1 NPT Female thread, SAE J514/ISO/ DIS11926-1 Female thread, DIN 2353 / ISO 8343-1 Heavy series, others on request MATERIAL CODE DESCRIPTION • Locking devices • Mounting holes • Position switches Ball seats Body and stem sealing Tmin / Tmax GENERAL DIMENSIONS Type HFKH500 also available as automated version Your ball valve shall be automated? No problem! Upon request, you can have your ball valve equipped with a pneumatic, electric or hydraulic actuator. By adding accessories such as limit switch boxes or...

Open the catalog to page 10

Block ball valve Stainless Steel CONNECTION TYPE Ready ORDER CODE PER MATERIAL COMBINATION ANSI B1.20.1 NPT FEMALE THREAD Please note the pressure ratings of the tube connections!

Open the catalog to page 11

Block ball valve Stainless Steel AVAILABLE SIZES DIN ISO 228 Female thread, ANSI B1.20.1 NPT Female thread, SAE J514/ISO/ DIS11926-1 Female thread, DIN 2353 / ISO 8343-1 Heavy series, C&T medium Pressure, others on request MATERIAL CODE DESCRIPTION • Locking devices • Mounting holes • Position switches Ball seats Body and stem sealing Tmin / Tmax HFKH650 also available as automated version Your ball valve shall be automated? No problem! Upon request, you can have your ball valve equipped with a pneumatic, electric or hydraulic actuator. By adding accessories such as limit switch boxes or...

Open the catalog to page 12All MHA ZENTGRAF GmbH & Co. KG catalogs and technical brochures

-

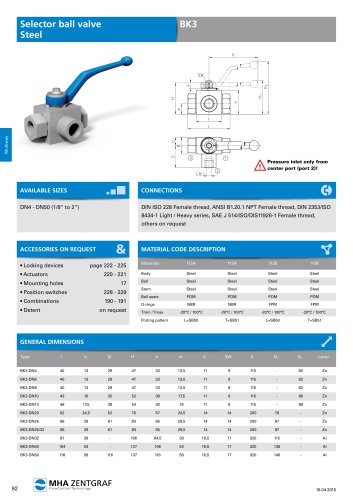

PK3-S

2 Pages

-

MPKH3

2 Pages

-

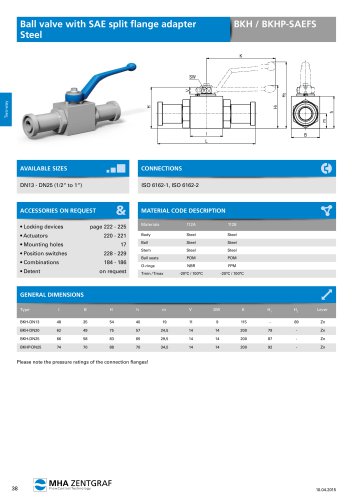

BK3K-SAE

1 Pages

-

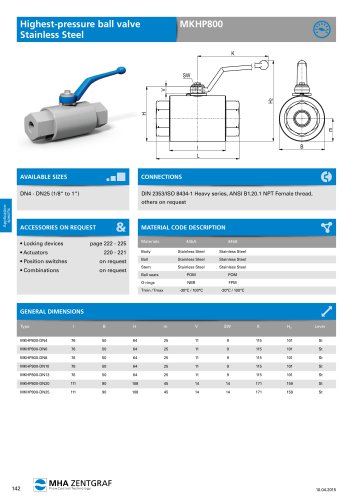

MKHP800

2 Pages

-

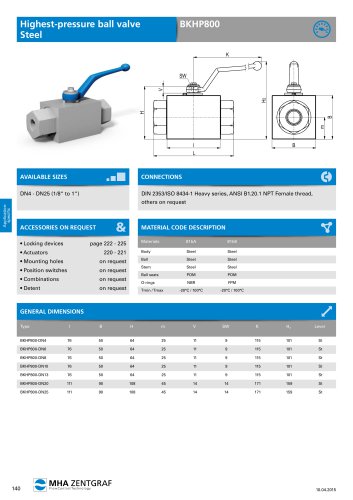

BKHP800

2 Pages

-

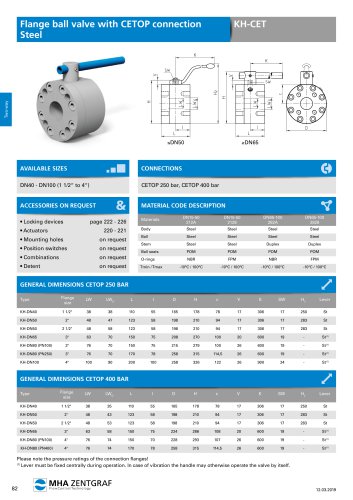

KH-CET

2 Pages

-

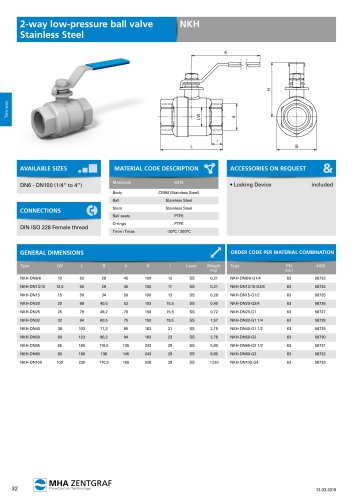

NKH

2 Pages

-

KHZ

2 Pages

-

MKHP-SAE

2 Pages

-

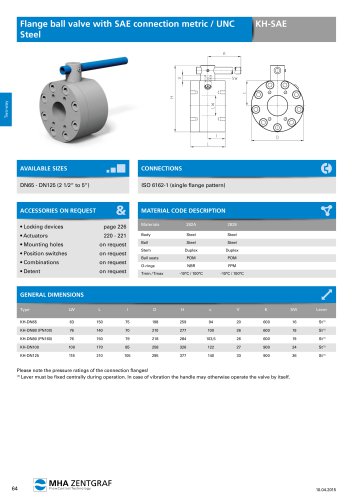

KH-SAE

2 Pages

-

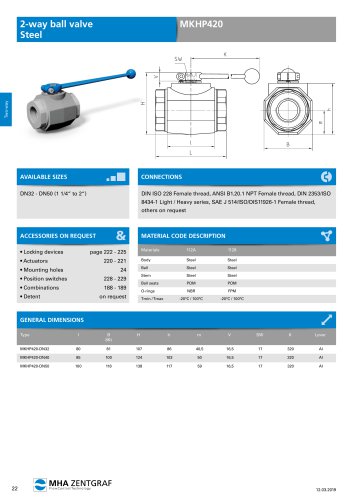

MKHP420

3 Pages

-

INDUSTRY SOLUTIONS

24 Pages

-

BASIC PROGRAM

20 Pages

-

MHA ZENTGRAF CATALOG

308 Pages

-

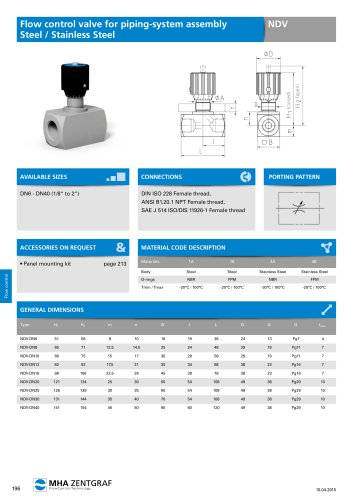

NDV

4 Pages

-

MPKH4

2 Pages

-

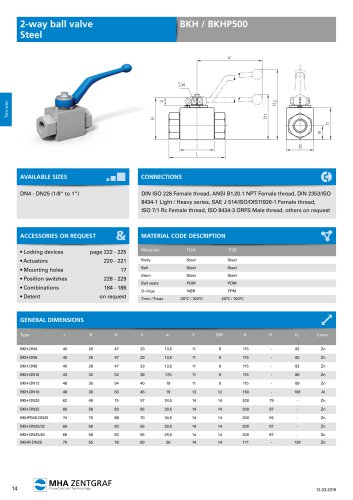

BKH / BKHP500

4 Pages