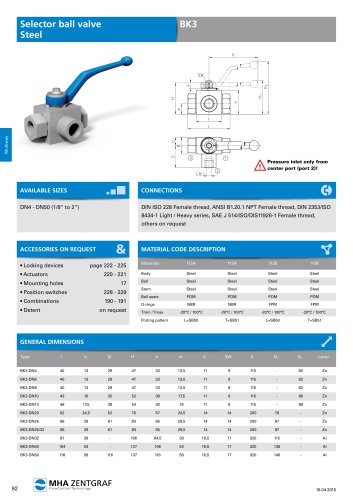

Catalog excerpts

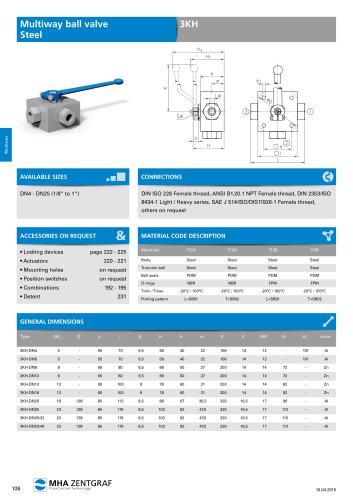

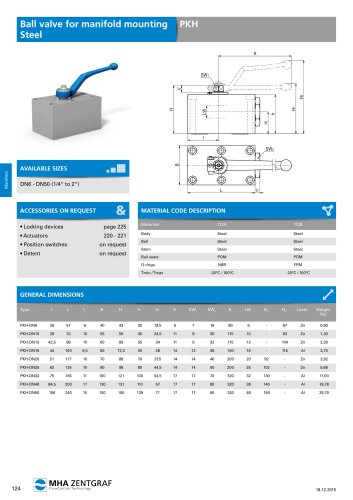

Multiway ball valve for manifold mounting Steel MATERIAL CODE DESCRIPTION Materials • Position switches Trunnion ball Ball seats • Locking devices Tmin / Tmax Porting pattern GENERAL DIMENSIONS Type Lever must be fixed centrally during operation. In case of vibration the lever may otherwise operate the valve by itse

Open the catalog to page 1

Multiway ball valve for manifold mounting Steel o-rings belong O-rings included to delivery ORDER CODE PER MATERIAL COMBINATION CONNECTION DIMENSIONS Type Due to material availability the material code of the steel valves may vary from 112A (or 1128). DN13-40=812A (or 8128). Material suitability for the application does not differ from 112A (or 1128). FLOW CHARACTERISTICS MPKH-X/T PORTING PATTERNS Further porting patterns page 262 to 267 ∆p (bar) ΔP [bar] The flow values are measured with usage of hydraulic oil (spissitude 880 kg/m3) and the kinematic viscosity of 35 m

Open the catalog to page 2All MHA ZENTGRAF GmbH & Co. KG catalogs and technical brochures

-

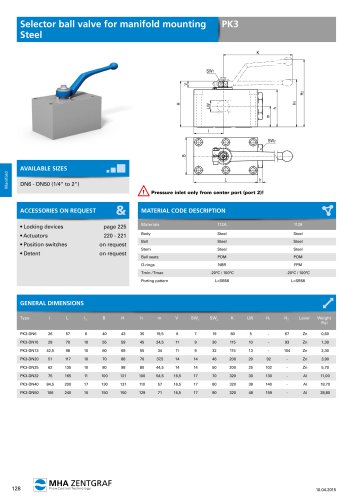

PK3-S

2 Pages

-

MPKH3

2 Pages

-

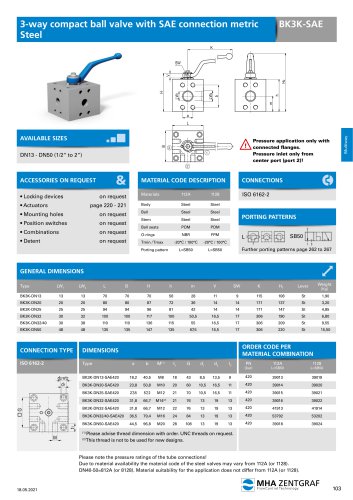

BK3K-SAE

1 Pages

-

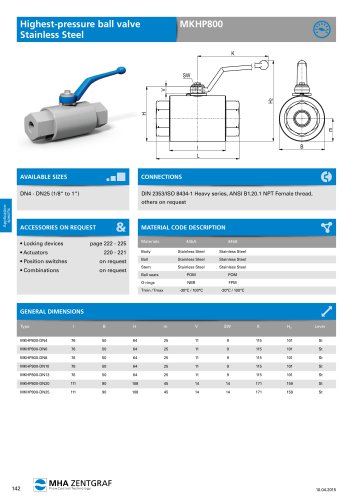

MKHP800

2 Pages

-

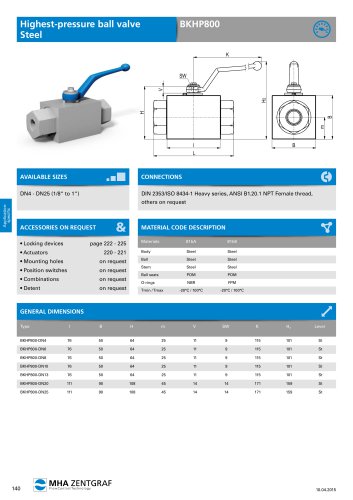

BKHP800

2 Pages

-

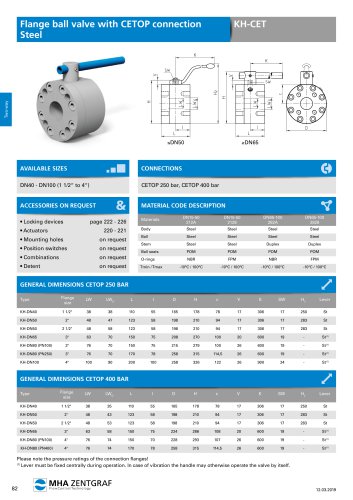

KH-CET

2 Pages

-

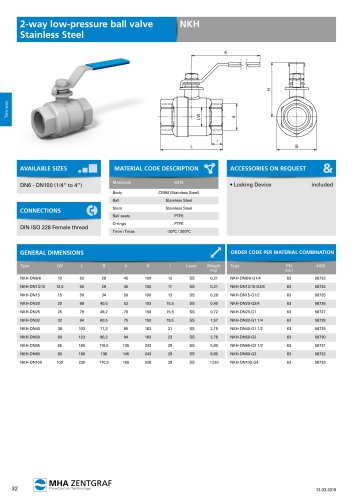

NKH

2 Pages

-

KHZ

2 Pages

-

MKHP-SAE

2 Pages

-

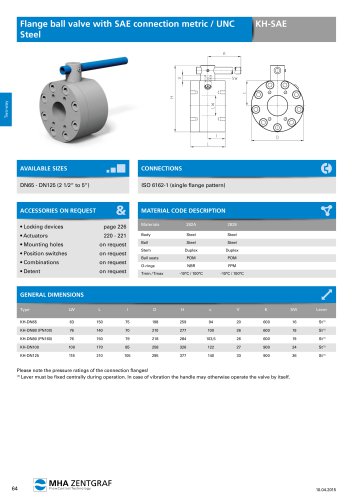

KH-SAE

2 Pages

-

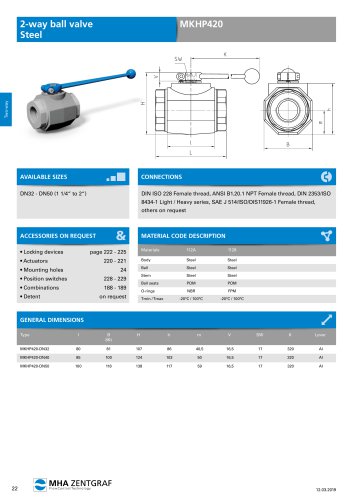

MKHP420

3 Pages

-

HYDROGEN BALL VALVES

16 Pages

-

INDUSTRY SOLUTIONS

24 Pages

-

BASIC PROGRAM

20 Pages

-

MHA ZENTGRAF CATALOG

308 Pages

-

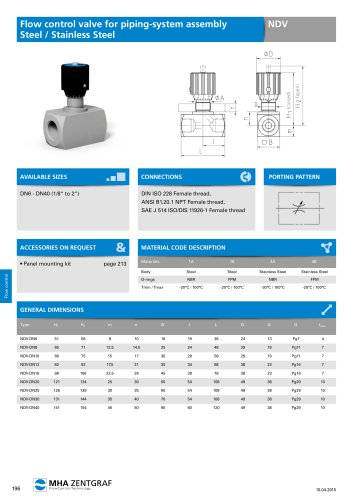

NDV

4 Pages

-

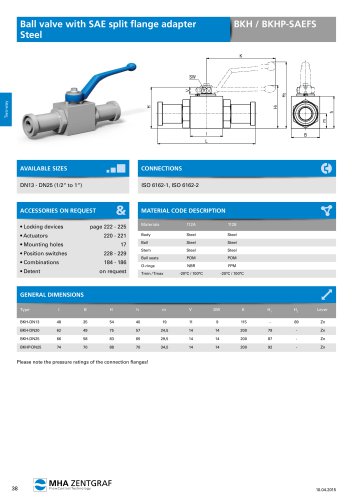

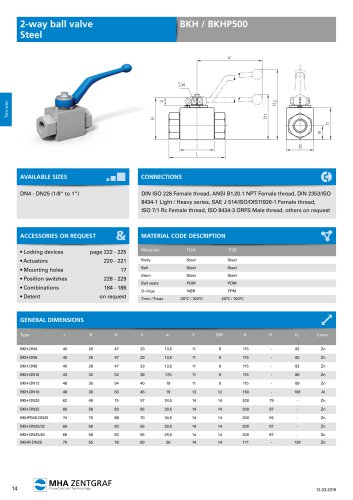

BKH / BKHP500

4 Pages