Catalog excerpts

Tube press Higher degree of separation

Open the catalog to page 1

Tube Press The Tube Press is a membrane type filter press designed in cylindrical format and capable of o perating at high filtration pressures up to 100 bar. • Where cake is to be disposed of to landfill The use of these high pressures enables a higher degree of separation of the liquid and solid phases. The process slurry is pumped into the annular space between the filter media and the bladder. Hydraulic fluid, usually water, is then pumped between the ladder and the casb ing putting the slurry under pressures and Principle of operation Filtration takes place between two concentric...

Open the catalog to page 2

complete the candle loses to the slurry fill c position to repeat the cycle. Air purge and/or cake wash can be incorporated into the cycle. At the completion of the ltration element, air or wash fluid is fi pumped between the cake and the bladder which is then forced through the cake by a further application of hydraulic ressure to p be incorporated into the cycle. Benefits • Driest possible cake solids • Maximum volume reduction • Exceptionally clear filtrate Advantages of on-site tube press Tests will be undertaken on production s lurry and will encounter any variability of p...

Open the catalog to page 3

Typical filtercake moisture contents (Filtration Pressure 102 BAR). Coal fines and shales 19% Calcium carbonate precipitates 30% Magnesite Dyestuffs/Pigments Para-goethite China clay Metal Sulphides Iron oxide fume Quarry clay slimes Seawater magnesia Lead chromate retrieval Zeolites Oxalates Molybdenum Zinc Concentrate Copper Concentrate Gold Concentrate Jarosite Titanium Dioxide Nickel Concentrate Silica Dioxide

Open the catalog to page 4

Mobile test plant rig Superior performance Laboratory and rental service Porosity and cake moisture contents are s ignificantly lower than those obtained with low pressure filters, consequently filtrate recovery is high. Filtration is conducted at a pressure level where the cake is produced as a hard surface dry, lump solid. Cake handling procedures are greatly implified compared with those s for low pressure filter cakes, which are typically plastic or paste-like and frequently surface wet. Metso can filter your product on both a p reliminary feasibility or on a full-scale p ...

Open the catalog to page 5

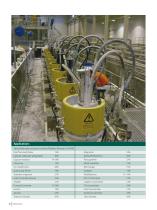

Typical tube press flowsheet Two tube module inclusive of ancillary pumps and hydraulic water systems. The tube press process Slurry feed Cycle start Tube Press Fill Cake discharge Hydraulic vacuum Hydraulic vacuum Hydraulic high pressure Hydraulic vacuum Cake forming Hydraulic vacuum Hydraulic vacuum Hydraulic high pressure Hydraulic vacuum Flitrate discharge Candle lowered Cake discharging

Open the catalog to page 6

Tube press - Sizes The Tube Press 500 serie is available mainly In two different sizes. 500 series. Casing diameter 500 mm. Nominal lengths available 1 500 mm and 3000 mm. Maximum pressure 100 bar (1 450 psi). Model 500 Series 1.5 m 500 Series 3 m Filtration pressure - max. (bar) Effective volume (litres) Model L mm (inch) W mm (inch) Weight (empty) Filter area Max op. pressure tube length ton m2 (ft2) bar (psi) SC 500-1,2 3 500 (138) 860 (34) 1.8 1.35 (14.5) 100 (1 450)

Open the catalog to page 7

• Metso Minerals Industries, Inc. 2715 Pleasent Valley Road, York, PA 17402, USA, Phone: +1 717 843 8671 • etso Minerals (South Africa) (Pty) Ltd. M Private Bag X2006, Isando, Johannesburg,1600, South Africa, Phone: +27 11 961 4000, Fax: +27 11 397 2050 • Metso Minerals (Australia) Ltd. Level 2, 1110 Hay Street, West Perth, WA 6005, Australia, Phone: +61 8 9420 5555, Fax: +61 8 9320 2500 • Metso Minerals (India) Pvt Ltd 1th floor, DLF Building No. 10, Tower A, DLF Cyber City, Phase - III, Gurgaon - 122 002, India, Phone: +91 124 235 1541, Fax: +91 124 235 1601 • Metso Perú S.A. Calle 5 Nro....

Open the catalog to page 8All Metso Corporation catalogs and technical brochures

-

RCSTM flotation cell

8 Pages

-

MHC™ Series Hydrocyclone

5 Pages

-

Superdeal® and Goodeal

6 Pages

-

Metso Vertimills®

12 Pages

-

HRC™

7 Pages

-

Nordtrack™ mobile solutions

36 Pages

-

Microcel™

6 Pages

-

Nordberg® HP900

2 Pages

-

Metso Air Classifiers

4 Pages

-

Trellex FLEXOPIPE® Brochure

8 Pages

-

Conveyor Belts Solutions Handbook

158 Pages

-

Trellex Poly-Cer Brochure

9 Pages

-

Trellex SQ300 Brochure

4 Pages

-

Belt Feeders Brochure

4 Pages

-

Wobble Feeders Brochure

4 Pages

-

Apron Feeders Brochure

8 Pages

-

Balance Crane Brochure

8 Pages

-

Pebble Lime Cooler Brochure

4 Pages

-

Spiral Dewaterer Brochure

8 Pages

-

Metso in Filtration

8 Pages

-

LIMS Programs Brochure

4 Pages

-

LIMS Wet Drum Iron Ore Brochure

12 Pages

-

Metso Ball Mills Brochure

3 Pages

-

Metso QdX4TM Mill Brochure

4 Pages

-

Minerals processing equipment

24 Pages