Catalog excerpts

Screening and Conveyor Solutions Trellex Loading Station Expect results

Open the catalog to page 1

Screening and Conveyor Solutions

Open the catalog to page 2

Trellex Loading Station – for critical points in material handling Loading is normally the critical point for the conveyor belt where many incidents of damage occur. The material drop height, lump size, speed and direction are all contributory factors to causing damage to belts, conveyors and conventional idler sets. Such problems are virtually eliminated using the Trellex Loading System. The system replaces conventional conveyor rollers and absorbs the impact energy from falling rocks while supporting the edge of the belt. The conveyor belt is protected from shearing and the risk for belt...

Open the catalog to page 3

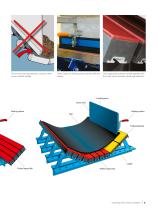

The adapter installed slightly below the belt, to absorb impact without constant wear. An adapter allows existing idler support to be used. The optimal construction for installation and servicing is achieved by using a cradle. Quick and easy fitting reduces downtime Loading zone Chute wall The fastening system with T-bolts means rapid and simple mounting. Selecting Trellex Adapter, which provides the option of using existing belt conveyor rollers, further helps installation. The most stable and complete construction for installation and control is achieved by using a complete cradle unit...

Open the catalog to page 4

The conveyor belt sag between conveyor rollers causes material spillage Trellex Clamp-On Sealing system provides effective sealing. The longitudinal aluminium profile to gether with the T-bolt system provides simple and reliable fit. Loading zone Chute wall Sealing system Sealing system Belt Cradle Trellex Impact Bar Screening and Conveyor Solutions

Open the catalog to page 5

Impact cradle installed slightly below the belt, to absorb impact without constant wear. T-bolt system To be used in existing idler support t = sag in mm a = engt of Trellex Impact bar installation in mm l T = elt tension in the relevant belt section in Newton (N) b g = 9.81 m/s2 qB = elt weight per meter (kg/m) b qG = weight of transported material per meter (kg/m) In this example the belt is sagging 10 mm per 1220 mm. To avoid continuous friction, 15 mm clearance needs to be added giving a total distance of 25 mm. Screening and Conveyor Solutions Trellex Impact bar Top layer: Intermediate...

Open the catalog to page 6

Trellex Snap-On Sealing System Trellex Clamp-On Sealing System Trellex Snap-On Sealing System Product description Trellex Snap-On Sealing System for sealing conveyor belts in loading zones. Characteristics The Trellex Snap-On is an effective system that is suitable for sealing at loading zones alternatively along the whole conveyor belt. The extruded rubber sealings can be obtained in long lengths, which reduces the number of joints and the risk of spillage. Snap-on elements are easy and quick to install. Adjustment of the rubber sealing against the conveyor belt is done by slackening the...

Open the catalog to page 7

Metso Minerals (Sweden) AB Screening and Conveyor Solutions P.O. Box 132 SE-231 22 Trelleborg Sweden Phone: +46 410 525 00 Fax: +46 410 526 04 www.metsominerals.com For contact or information about your nearest sales office please visit: www.metso.com Subject to alteration without prior notice.

Open the catalog to page 8All Metso Automation catalogs and technical brochures

-

Metallrecycling-Services

12 Pages

-

EtaCrush® series

1 Pages

-

more capability brochure

4 Pages

-

Neles Flow Control Solutions

12 Pages

-

Crushing and screening solutions

51 Pages

-

Primary gyratory stations

9 Pages

-

Process Capacity IPS

6 Pages

-

Slurry Hose System

20 Pages

-

Mill discharge pumps

8 Pages

-

Slurry pump basic

204 Pages

-

STGVA - STHM

8 Pages

-

Metso Slurry Pump program

16 Pages

-

Vasa HD

4 Pages

-

Metso Balance Cranes (MBC)

8 Pages

-

Aftermarket Training

2 Pages

-

Hot Kiln Survey

2 Pages

-

Holo-Flite®

8 Pages

-

Dryers and Coolers

6 Pages

-

Coke Calcining Systems

8 Pages

-

Metso pebble lime cooler

4 Pages

-

Spiral Dewaterers

8 Pages

-

LIMS dry drum

4 Pages

-

HGMS cyclic

5 Pages

-

HGMS

12 Pages

-

HGMS Continuous

8 Pages

-

HGMF

8 Pages

-

LIMS iron ore

12 Pages

-

IPS LTK

1 Pages

-

Inclined Plate Settler

8 Pages

-

Microcel Flotation Columns

6 Pages

-

Flotation Machines DR

8 Pages

-

Feed Forward for Flotation

2 Pages

-

Flotation Machines RCS

8 Pages

-

Tube press

8 Pages

-

Tube press booster range

8 Pages

-

Metso in filtration

8 Pages

-

High efficiency cyclones

2 Pages

-

Air Classifiers

4 Pages

-

Gearless AG/SAG Mills

2 Pages

-

Vertimill for limeslaking

2 Pages

-

Grinding and enrichment

12 Pages

-

Flue Gas Desulfurization

4 Pages

-

Ball mills

2 Pages

-

Apron feeders

8 Pages

-

Wobbler feeders

4 Pages

-

Lokotrack CT3.2 and CW3

2 Pages

-

HRC 800

8 Pages

-

MP1250 Cone crusher

6 Pages

-

Metso screening media

114 Pages

-

Trellex dust control

8 Pages

-

Metso lining and sheeting

44 Pages

-

Trellex wear lining solutions

16 Pages

-

Trellex PSV conveyor rollers

4 Pages

-

Trellex flexopipe

8 Pages

-

Trellex belt cleaning

12 Pages

-

Trellex Cer-Lag

4 Pages

-

Trellex belt guiding system

8 Pages

-

Trellex conveyor accessories

12 Pages

-

Jamesbury Valve Solutions

28 Pages

-

Actuator

2 Pages

-

Chlorine

4 Pages

-

Metso DNA Drive Controls

2 Pages

-

Flow control solutions

12 Pages

Archived catalogs

-

Metso_MCA_brochure

6 Pages

-

TheArtOfConsistency_brochure

8 Pages

-

MetsoPulpExpert_brochure

8 Pages

-

Metso_FS300_brochure

4 Pages

-

Alkali Analyser

4 Pages

-

SmartLX

6 Pages

-

Neles SwitchGuard

6 Pages

-

Pneumatic Actuator

10 Pages

-

Butterfly Valves

20 Pages

-

Series 3000 Ball Valves

4 Pages

-

Neles Manual Gear Actuators

2 Pages

-

Actuator Accessories

2 Pages