Catalog excerpts

Screening Media Solutions Trellex® Dust Control EN

Open the catalog to page 1

Take the dust and noise out of materials handling Dust means trouble! Modern large-scale mining and mineralprocessing facilities generate dust and noise in a big way. And there isn’t much good that can be said about dust. It’s an acknowledged health hazard. It also accelerates wear on machinery and equipment. It also accelerates corrosion. It makes maintenance and repair more difficult and more time-consuming. We supply off the shelf standardized solutions for dust control of screens, feeders, chutes and other equipment that handles dust. The elasticity of Trellex rubber enables it to be...

Open the catalog to page 3

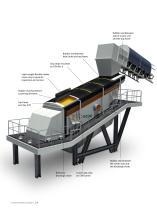

Trellex 300TS with flexible rubber prevents blinding The simple, cost-effective answer Totally sealed screen or feeder Chute cover Several decades ago, Metso began delivering dust-sealing systems that provide dramatic improvements to equipment handling dust. These systems are based on three types of components: Trellex dust sealing cloth and fabric Rubber grip strips STM steel profiles Chute Seal These drawings show how a typical screen can be totally encapsulated with a Trellex dust-sealing system, which effectively prevents dust from escaping out into the environment and into the drive...

Open the catalog to page 4

No need to suck out dust A quarry (capacity 500 MTPH [550 STPH] ) with a very high content of silica in its rock, reduced the need for sucked air from 530 thousand m3/h to 35 thousand m3/h (19x106 ft3/h to 12x105 ft3/h), the dust content from 25 mg/m3 to 0.5 mg/m3 (9.03x10-10 lbs/in3 to 2x10-11 lbs/in3) and the noise level from 95 dB to 76 dB using Trellex dust seals, screening media and chute linings. Considerable noise reduction Summary Trellex dust-sealing system ensures much less dust and much less noise. Which means: A better working environment Reduced wear and corrosion Safe, fast...

Open the catalog to page 5

STM 10A top frame side profile Dust is pushed to the bottom due to underpressure. Section through dust-sealed screen Screening Media Solutions

Open the catalog to page 6

Rubber seal between side of screen unit and the top frame Rubber seal between feed chute and top frame Grip strips mounted on STM No. 9 Light-weight flexible rubber cover easy to open for inspection and service Rubber or polyurethane screening elements Rubber seal between the screen unit and the discharge chute Roll-away discharge chute Screening Media Solutions Corner grip strip on STM corner

Open the catalog to page 7

Metso Minerals (Sweden) AB Screening Media Solutions P.O. Box 74 SE-231 21 Trelleborg Sweden Phone: +46 410 525 00 Fax: +46 410 526 04 www.metso.com For contact with your local Metso representative, visit www.metso.com for information about your nearest sales office. Subject to alteration without prior notice.

Open the catalog to page 8All Metso Automation catalogs and technical brochures

-

Metallrecycling-Services

12 Pages

-

EtaCrush® series

1 Pages

-

more capability brochure

4 Pages

-

Neles Flow Control Solutions

12 Pages

-

Crushing and screening solutions

51 Pages

-

Primary gyratory stations

9 Pages

-

Process Capacity IPS

6 Pages

-

Slurry Hose System

20 Pages

-

Mill discharge pumps

8 Pages

-

Slurry pump basic

204 Pages

-

STGVA - STHM

8 Pages

-

Metso Slurry Pump program

16 Pages

-

Vasa HD

4 Pages

-

Metso Balance Cranes (MBC)

8 Pages

-

Aftermarket Training

2 Pages

-

Hot Kiln Survey

2 Pages

-

Holo-Flite®

8 Pages

-

Dryers and Coolers

6 Pages

-

Coke Calcining Systems

8 Pages

-

Metso pebble lime cooler

4 Pages

-

Spiral Dewaterers

8 Pages

-

LIMS dry drum

4 Pages

-

HGMS cyclic

5 Pages

-

HGMS

12 Pages

-

HGMS Continuous

8 Pages

-

HGMF

8 Pages

-

LIMS iron ore

12 Pages

-

IPS LTK

1 Pages

-

Inclined Plate Settler

8 Pages

-

Microcel Flotation Columns

6 Pages

-

Flotation Machines DR

8 Pages

-

Feed Forward for Flotation

2 Pages

-

Flotation Machines RCS

8 Pages

-

Tube press

8 Pages

-

Tube press booster range

8 Pages

-

Metso in filtration

8 Pages

-

High efficiency cyclones

2 Pages

-

Air Classifiers

4 Pages

-

Gearless AG/SAG Mills

2 Pages

-

Vertimill for limeslaking

2 Pages

-

Grinding and enrichment

12 Pages

-

Flue Gas Desulfurization

4 Pages

-

Ball mills

2 Pages

-

Apron feeders

8 Pages

-

Wobbler feeders

4 Pages

-

Lokotrack CT3.2 and CW3

2 Pages

-

HRC 800

8 Pages

-

MP1250 Cone crusher

6 Pages

-

Metso screening media

114 Pages

-

Metso lining and sheeting

44 Pages

-

Trellex wear lining solutions

16 Pages

-

Trellex PSV conveyor rollers

4 Pages

-

Trellex flexopipe

8 Pages

-

Trellex belt cleaning

12 Pages

-

Trellex loading stations

8 Pages

-

Trellex Cer-Lag

4 Pages

-

Trellex belt guiding system

8 Pages

-

Trellex conveyor accessories

12 Pages

-

Jamesbury Valve Solutions

28 Pages

-

Actuator

2 Pages

-

Chlorine

4 Pages

-

Metso DNA Drive Controls

2 Pages

-

Flow control solutions

12 Pages

Archived catalogs

-

Metso_MCA_brochure

6 Pages

-

TheArtOfConsistency_brochure

8 Pages

-

MetsoPulpExpert_brochure

8 Pages

-

Metso_FS300_brochure

4 Pages

-

Alkali Analyser

4 Pages

-

SmartLX

6 Pages

-

Neles SwitchGuard

6 Pages

-

Pneumatic Actuator

10 Pages

-

Butterfly Valves

20 Pages

-

Series 3000 Ball Valves

4 Pages

-

Neles Manual Gear Actuators

2 Pages

-

Actuator Accessories

2 Pages