Catalog excerpts

Metso SUPERIOR® gyratory crushers SUPERIOR Gyratory Crushers Brochure 2012.indd 1

Open the catalog to page 1

Metso SUPERIOR® primary gyratory – the first step in high-capacity crushing Years of experience and thousands of primary gyratory installations combine to create the best gyratory the industry has to offer. Metso SUPERIOR gyratory crushers are built to help you meet the challenges of highcapacity primary crushing. With thousands of units operating in mines and quarries around the world, Metso has the experience and capabilities to provide the top performance, throughput and efficiency. Low cost per ton In today’s competitive market, environmental concerns and energy costs are on the rise....

Open the catalog to page 2

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine Metso’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant. • steep crushing chamber and long crushing surfaces for A exceptionally high capacity and maximum liner life • Automatic spider lubrication • extra heavy-duty frame, large diameter integral mainshaft An...

Open the catalog to page 3

Metso Services Make the most of your investment Achieve your goals with a partner who will be there wherever and whenever you need them. Metso offers a host of value-added services that can enhance your bottom line and help you make the most of your SUPERIOR primary gyratory. Whether you’re installing an entire customized system, a complete circuit, or simply replacing or updating a single piece of equipment, you can count on us to help you make sure your crusher is running at peak efficiency. Life cycle thinking Using our long-term experience in crushing equipment and processes, Metso has...

Open the catalog to page 4

Plant diagnostics and upgrade Engineering analysis of your crushing circuit can substantially increase production. Metso experts can determine the correct set up of your primary and downstream crushers for optimum equipment application and plant productivity. Training Metso training can ensure that your operators are familiar with all the features of the crusher they are using. Properly trained operators gain knowledge of proper procedures, all feature functions, productivity tips, and important safety measures. We offer a broad range of training courses coached by experienced professionals...

Open the catalog to page 5

Advanced features Metso has optimized the SUPERIOR design with one thing in mind — to be the most productive, reliable and efficient primary gyratory crushers on the market. The SUPERIOR range provides innovative, exclusive features with the power and performance to operate in the most demanding conditions. Mainshaft position control The mainshaft position system — successfully used for decades — is a hydraulic method of vertical adjustment to compensate for wear. It consists of a pump, controlled by a push-button, and a heavy-duty hydraulic cylinder that supports and adjusts the mainshaft...

Open the catalog to page 6

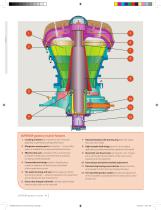

SUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2 Manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 High-strength shell design, proven in the toughest applications, provides trouble-free operation and long life 3 Effective dust seal is equipped with an overpressure air blower to keep dust out of the eccentric and drive, increasing crusher bearing life 9 Mainshaft and head...

Open the catalog to page 7

Proper installation is key Feed and discharge arrangements can greatly affect crusher reliability and performance. Basic recommendations are: Proper feeding will result in the following: • Position spider arm in line with truck discharge. The arm will split material flow into the crushing chamber for more even feed distribution • Increased crushing chamber wear life • Construct a stone box around the spider so material discharge from truck dumping falls on dead stone bed before entering the crushing chamber • Avoid direct impact of dumped material on the spider cap or mainshaft assembly •...

Open the catalog to page 8

Total crusher and process control Metso’s TC1000-C automation system contributes to a higher return on your investment by improving overall crusher control, maximizing availability, and minimizing maintenance and energy costs. Total crusher control Every aspect of the crusher is controlled by the TC System. The entire lubrication system is controlled, including the air blower, immersion heaters, lube pump, and oil coolers. The TC1000-C automation system (available as an option) simplifies operation and provides real-time information about the condition of the crusher: Asset protection...

Open the catalog to page 9

Capacities Open side settings of discharge opening The above capacities are based on an assumed feed where 100% of the feed passes 80% of the feed opening. 80% of the feed passes 60% of the feed topsize, and 50% of the feed passes a sieve size that is 10% of the topsize. The capacities are for feed materials with a bulk density of 1.6 metric tons per cubic meter (100 pounds per cubic foot). All capacities are calculated at a maximum throw for each respective machine. All capacities are relative to individual application. Material characteristics, feed size, distribution, work index, percent...

Open the catalog to page 10

Dimensions Crusher Size 42-65 Mainshaft assembly removal Eccentric lowered on skid Recommended discharge pocket si

Open the catalog to page 11

Expect results It is our promise to our customers and the essence of our strategy. Metso Minerals Industries, Inc., 20965 Crossroads Circle, Waukesha, WI 53186, USA, tel +1 262 717 2500, fax +1 262 717 2501, www.metso.com SUPERIOR Gyratory Crushers Brochure 2012.indd 2 It is the attitude we share globally; our business is to deliver results to our customers, to help them reach their goals.

Open the catalog to page 12All Metso Automation catalogs and technical brochures

-

Metallrecycling-Services

12 Pages

-

EtaCrush® series

1 Pages

-

more capability brochure

4 Pages

-

Neles Flow Control Solutions

12 Pages

-

Crushing and screening solutions

51 Pages

-

Primary gyratory stations

9 Pages

-

Process Capacity IPS

6 Pages

-

Slurry Hose System

20 Pages

-

Mill discharge pumps

8 Pages

-

Slurry pump basic

204 Pages

-

STGVA - STHM

8 Pages

-

Metso Slurry Pump program

16 Pages

-

Vasa HD

4 Pages

-

Metso Balance Cranes (MBC)

8 Pages

-

Aftermarket Training

2 Pages

-

Hot Kiln Survey

2 Pages

-

Holo-Flite®

8 Pages

-

Dryers and Coolers

6 Pages

-

Coke Calcining Systems

8 Pages

-

Metso pebble lime cooler

4 Pages

-

Spiral Dewaterers

8 Pages

-

LIMS dry drum

4 Pages

-

HGMS cyclic

5 Pages

-

HGMS

12 Pages

-

HGMS Continuous

8 Pages

-

HGMF

8 Pages

-

LIMS iron ore

12 Pages

-

IPS LTK

1 Pages

-

Inclined Plate Settler

8 Pages

-

Microcel Flotation Columns

6 Pages

-

Flotation Machines DR

8 Pages

-

Feed Forward for Flotation

2 Pages

-

Flotation Machines RCS

8 Pages

-

Tube press

8 Pages

-

Tube press booster range

8 Pages

-

Metso in filtration

8 Pages

-

High efficiency cyclones

2 Pages

-

Air Classifiers

4 Pages

-

Gearless AG/SAG Mills

2 Pages

-

Vertimill for limeslaking

2 Pages

-

Grinding and enrichment

12 Pages

-

Flue Gas Desulfurization

4 Pages

-

Ball mills

2 Pages

-

Apron feeders

8 Pages

-

Wobbler feeders

4 Pages

-

Lokotrack CT3.2 and CW3

2 Pages

-

HRC 800

8 Pages

-

MP1250 Cone crusher

6 Pages

-

Metso screening media

114 Pages

-

Trellex dust control

8 Pages

-

Metso lining and sheeting

44 Pages

-

Trellex wear lining solutions

16 Pages

-

Trellex PSV conveyor rollers

4 Pages

-

Trellex flexopipe

8 Pages

-

Trellex belt cleaning

12 Pages

-

Trellex loading stations

8 Pages

-

Trellex Cer-Lag

4 Pages

-

Trellex belt guiding system

8 Pages

-

Trellex conveyor accessories

12 Pages

-

Jamesbury Valve Solutions

28 Pages

-

Actuator

2 Pages

-

Chlorine

4 Pages

-

Metso DNA Drive Controls

2 Pages

-

Flow control solutions

12 Pages

Archived catalogs

-

Metso_MCA_brochure

6 Pages

-

TheArtOfConsistency_brochure

8 Pages

-

MetsoPulpExpert_brochure

8 Pages

-

Metso_FS300_brochure

4 Pages

-

Alkali Analyser

4 Pages

-

SmartLX

6 Pages

-

Neles SwitchGuard

6 Pages

-

Pneumatic Actuator

10 Pages

-

Butterfly Valves

20 Pages

-

Series 3000 Ball Valves

4 Pages

-

Neles Manual Gear Actuators

2 Pages

-

Actuator Accessories

2 Pages