Catalog excerpts

Metso Screening media Handbook Metso Minerals (Sweden) AB, Terminalsgatan 2, P.O. Box 132, SE-231 22 Trelleborg, Sweden, tel. +46 410 525 00, fax +46 410 526 02, www.metso.com

Open the catalog to page 1

Trellex® is a registered trademark of Metso Corporation Introduction Working together for you. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Screening media and lining solutions you can count on . . . . 4 Advancing efficiency gains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Applications Mining applications Pre-grinding ore. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Pre-heap leach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 High grade ferrous ore....

Open the catalog to page 2

screening media Working together Metso is a global supplier of sustainable technology and services for mining, construction and oil & gas industries. As a fullservice partner to these industries, Metso relies on a global pool of more than 15,000 dedicated employees to help our customers achieve successful results in every part of their operation. Metso screening media solutions reflect that commitment in every product and service we offer. Working closely with our customers, we go beyond simply being a supplier to consulting on and recommending genuinely customized solutions that help...

Open the catalog to page 3

screening media Screening media solutions you can count on Whatever the application, there is a Metso screening media solution to match. Metso screening media are adaptable to all environments and tasks. The range is designed to offer maximum productivity without compromising quality. Options are available from fine to coarse in both wet and dry applications. Media equipment is made of the wear-resistant material best suited to the screening process and budget, and is easily adaptable for stationary and mobile crushing plants. Trellex LS This modern range of modular screening Trellex 610MP...

Open the catalog to page 4

screening media Production and material technology As developments in materials technology continues to grow, so does Metso innovation in applying them to screening media. Steel is still the most widely used screening media material used today. But we believe that the best results for today’s mining and construction operations are achieved by combining materials such as steel, rubber/ polyurethane – and taking full advantage of the best features of each. Compared to steel screening media, for instance synthetic screening media offers outstanding wear life, resulting in maximum productivity....

Open the catalog to page 5

screening media mining applications Mining applications Pre-grinding ore Pre-heap leach High grade ferrous ore Mill discharge screens Dense media circuits Control screening - fines removal Construction applications Soft rock 24 Hard rock 26 Sand and gravel

Open the catalog to page 6

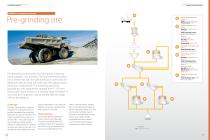

screening media mining applications MINING: Crushing & screening Primary screen area Secondary crusher area Secondary screens Primary crusher area Tertiary crusher area Pre-grinding is the process of crushing and screening ore to prepare it for grinding. The final screened product has a certain top size and size distribution optimized for feeding to the grinding mill with high throughput and a minimum of downtime. The screening process is typically dry with separations ranging from 5-150 mm. Using multi-slope screens in a “banana”-type formation is common as it’s a proven way to handle high...

Open the catalog to page 7

screening media mining applications MINING: Crushing & screening Pre-heap leach Ore being prepared for heap leach goes through a crushing and screening process. The typically dry screening aims for separations ranging from 5-150 mm, with top size and size distribution optimized for leaching. Multi-slope screens are often set “banana”-style for handling high tonnages of fines throughput. The final screened product is stacked and protected by a sealed surface for collecting the leaching chemicals. Challenges The main challenge is pretty straightforward – to achieve high volume throughput of...

Open the catalog to page 8

screening media mining applications MINING: Crushing & screening High grade ferrous ore In iron ore mines where the iron grade is very high, ore can be produced without enrichment or beneficiation. Instead, rock is blasted, crushed and screened down to lump iron ore (typically 6-20 mm) or iron ore fines (0-6 mm), depending on the grade needed for its final use. Lump iron ore is often used directly in the steel making process, while fines are reserved for making sinter lumps. Challenges For screening media and lining applications, high-grade ferrous ore production can be challenging. Heavy...

Open the catalog to page 9

screening media mining applications MINING: Copper/Gold ore grinding Mill discharge screens A This screening process, to control the top size of the final grinding ore, is set up at the discharge outlet of grinding mills. The objective is to remove oversized particles for further reduction to the optimal grinding size and any grinding balls or media. This is a wet screening process handled by trommel screens attached to the grinding mill or by separate horizontal vibrating screens, both single- and double-deck. D Challenges Maximum throughput with as little downtime as possible is the goal,...

Open the catalog to page 10

screening media mining applications MINING: Beneficiation Dense media circuits Screening during beneficiation processes come with their own set of challenges, especially the pegging and blinding that can occur when handling smaller sizes with high moisture. Normally the goal is to recover material with no losses – while minimizing downtime to keep plant productivity high. Desliming, DMS feed preparation Desliming screens are used to maximize efficiency in DMS plants – coal preparation is a common example. Screening media must be capable of separating at between 0,5 and 1,4 mm while at the...

Open the catalog to page 11

screening media mining applications MINING: Bulk handling Control screening – fines removal These plants are used for stocking, loading and unloading bulk materials such as coal, coke, lump iron ore, pellets, limestone and other commodities used by metal manufacturers or power plants. Regardless of the material, it is important to remove fines that could impact production further in the process prior to use. Challenges The main challenge is the weight and bed depth of the oversize. Special attention is usually needed for the screen media reinforcement structure to handle this. Also, some...

Open the catalog to page 12All Metso Automation catalogs and technical brochures

-

Metallrecycling-Services

12 Pages

-

EtaCrush® series

1 Pages

-

more capability brochure

4 Pages

-

Neles Flow Control Solutions

12 Pages

-

Crushing and screening solutions

51 Pages

-

Primary gyratory stations

9 Pages

-

Process Capacity IPS

6 Pages

-

Slurry Hose System

20 Pages

-

Mill discharge pumps

8 Pages

-

Slurry pump basic

204 Pages

-

STGVA - STHM

8 Pages

-

Metso Slurry Pump program

16 Pages

-

Vasa HD

4 Pages

-

Metso Balance Cranes (MBC)

8 Pages

-

Aftermarket Training

2 Pages

-

Hot Kiln Survey

2 Pages

-

Holo-Flite®

8 Pages

-

Dryers and Coolers

6 Pages

-

Coke Calcining Systems

8 Pages

-

Metso pebble lime cooler

4 Pages

-

Spiral Dewaterers

8 Pages

-

LIMS dry drum

4 Pages

-

HGMS cyclic

5 Pages

-

HGMS

12 Pages

-

HGMS Continuous

8 Pages

-

HGMF

8 Pages

-

LIMS iron ore

12 Pages

-

IPS LTK

1 Pages

-

Inclined Plate Settler

8 Pages

-

Microcel Flotation Columns

6 Pages

-

Flotation Machines DR

8 Pages

-

Feed Forward for Flotation

2 Pages

-

Flotation Machines RCS

8 Pages

-

Tube press

8 Pages

-

Tube press booster range

8 Pages

-

Metso in filtration

8 Pages

-

High efficiency cyclones

2 Pages

-

Air Classifiers

4 Pages

-

Gearless AG/SAG Mills

2 Pages

-

Vertimill for limeslaking

2 Pages

-

Grinding and enrichment

12 Pages

-

Flue Gas Desulfurization

4 Pages

-

Ball mills

2 Pages

-

Apron feeders

8 Pages

-

Wobbler feeders

4 Pages

-

Lokotrack CT3.2 and CW3

2 Pages

-

HRC 800

8 Pages

-

MP1250 Cone crusher

6 Pages

-

Trellex dust control

8 Pages

-

Metso lining and sheeting

44 Pages

-

Trellex wear lining solutions

16 Pages

-

Trellex PSV conveyor rollers

4 Pages

-

Trellex flexopipe

8 Pages

-

Trellex belt cleaning

12 Pages

-

Trellex loading stations

8 Pages

-

Trellex Cer-Lag

4 Pages

-

Trellex belt guiding system

8 Pages

-

Trellex conveyor accessories

12 Pages

-

Jamesbury Valve Solutions

28 Pages

-

Actuator

2 Pages

-

Chlorine

4 Pages

-

Metso DNA Drive Controls

2 Pages

-

Flow control solutions

12 Pages

Archived catalogs

-

Metso_MCA_brochure

6 Pages

-

TheArtOfConsistency_brochure

8 Pages

-

MetsoPulpExpert_brochure

8 Pages

-

Metso_FS300_brochure

4 Pages

-

Alkali Analyser

4 Pages

-

SmartLX

6 Pages

-

Neles SwitchGuard

6 Pages

-

Pneumatic Actuator

10 Pages

-

Butterfly Valves

20 Pages

-

Series 3000 Ball Valves

4 Pages

-

Neles Manual Gear Actuators

2 Pages

-

Actuator Accessories

2 Pages