Website:

METREL

Website:

METREL

A practical guide for erection and operation of electrical test equipment in accordance with EN 50191

1 /

32Pages

Catalog excerpts

A Practical Guide for erection and operation of electrical test equipment According to EN 50191

Open the catalog to page 1

Introduction Testing of the electrical devices during the production process is one of the fields in the more general electrical equipment testing. It requires special attention to the operator's safety. Test procedures require application of very high and dangerous test voltages, which cause heightened probability of electric shock. There are numerous types of electrical equipment that need to be inspected and tested during the manufacturing process. Metrel has developed a special model MI 3394 CE MultiTesterXS machine safety tester. With its safety modules and optional accessories it...

Open the catalog to page 2

Table of contents 1. Working places according to EN 50191 2.2.2. Allowable alternatives – when IP3X can be omitted 11 1.1. Scope of this document 2.2.3. Other possible omissions 1.1.3. Conditions where conforming to EN50191 is not required 1.2. General protective measures in test installations 1.2.1. Protection against direct contact 1.2.2. Protection against indirect contact (fault protection) 2.3. Test station without automatic protection against direct contact direct contact 4.3. Test station without automatic protection against direct contact 4.5. Temporary test station Permissible body...

Open the catalog to page 3

1. Working places according to EN 50191 1.1. Scope of this document This document is intended as a help when making work stations for testing safety of electrical equipment. If dangerous voltages, currents, residual charges and other hazard can occur in the work place the standard EN 50191: Erection and operation of electrical test equipment should be considered. Warning: This document is additional help with understanding the standard. It shall not be used as a substitute for the standard or other required documents. It does not reflect all points covered in EN 50191. • Test stations in...

Open the catalog to page 4

1.1.3. CONDITIONS WHERE CONFORMING TO EN 50191 IS NOT REQUIRED EN 50191 states that compliance is not necessary if contact with live parts of the work place presents no danger. This is true under one of the following conditions at live exposed points: values for permissible body currents and contact voltages will be taken from Table A.1. d) The discharge energy does not exceed 350 mJ. a) The voltage at frequencies above 500 Hz does not exceed 25 V a.c. or 60 V d.c. and complies with the requirements for SELV or for PELV in accordance with HD 60364-4-41. b) In case of voltages at frequencies...

Open the catalog to page 5

1.2. General protective measures in test installations In this chapter the key elements of protection in test installations are described. 1.2.1. PROTECTION AGAINST DIRECT CONTACT Protection against direct contact is the essential and the most important protective measure. It can be made by: • insulation of live parts everywhere in the installation (on test object, test equipment and test connections). • Assuring safe distances to live parts with barriers, covers, enclosures, obstacles etc. • Using two hand control devices that comply with EN 574. • Using two safety test probes. Clamping...

Open the catalog to page 6

area from other work areas. Their purpose is to prevent people other than the test personnel from: • accessing to the test area, • reaching the prohibition zone, • reaching the operating devices inside the test area. The minimum space the barriers provide are defined in Annex A (Table A.3 and Table A.4) of EN 50191. If barriers are conductive, they must be earthed or otherwise protected against indirect contact in case of fault. 1.2.5. USE OF INDICATOR LIGHTS, SIGNAL LIGHTS, WARNING SIGNS Indicators, lights, or signs on the control panels inside the test area should indicate the switching...

Open the catalog to page 7

2. Types of test installations 2.1. Test installation The test installation is the combination of all test devices, appliances and facilities necessary for testing. When designing a new work place the type of test installations needs to be defined. A test installation can be performed as: • Test station with automatic protection against direct contact. This type is common on serial production lines, and is also preferred in workshops, repair and service shops. • Test station without automatic protection against direct contact. This type is common in workshops or laboratories. The test...

Open the catalog to page 8

2.2. Test station with automatic protection against direct contact This is the preferred test installation type. Test station with automatic protection against direct contact is the preferred choice when setting up a work place. There are very few justified reasons to choose a different type and they are collected in in EN 50191, chapter 4.3.1. Mainly different types are chosen where automatic protection against direct contact is not possible or economical. 2.2.1. ARRANGEMENT OF AUTOMATIC PROTECTION AGAINST DIRECT CONTACT Protection grade of IP3X or higher Appropriate isolation (achieved...

Open the catalog to page 9

Comments in BGI 891 (chapter 3.2.6) According to EN 50191, one still effective protective measure in case of a single fault is enough to protect against indirect contact. For the test and measuring equipment, protection in case of a single fault must be guaranteed by design (with CE declaration - LVD, IEC/ EN 61010). However one protection in case of a single fault does not provide 100% safety. If another fault occurs, or in case of a combined fault, there is still a possibility of a dangerous electric shock. It is possible to make test installations with a higher degrees of protection. For...

Open the catalog to page 10

distance between beams not more than 14 mm can be used instead of the enclosure. Safety distance between the prohibition zone and detection zone, approach (breaching) speed and respond times of the protection/ switching devices must be considered. Instructions for calculation can be found in EN 999 Safety of machinery - the positioning of protective equipment in respect of approach speeds of parts of the human body. Solid walls or grids Barrier with height of least 1.8m (with mesh size < 40 mm or solid wall) must be placed as a barrier to the prohibition zone. Distances are given in EN...

Open the catalog to page 11All METREL catalogs and technical brochures

-

MI 3116 PV AnalyserXA

2 Pages

-

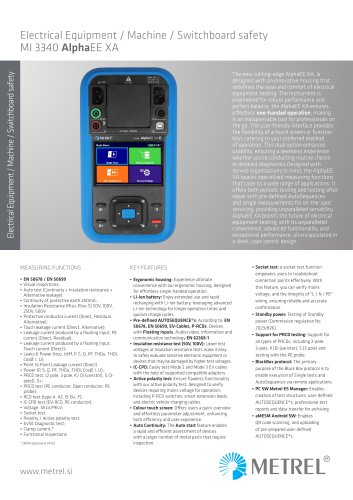

MI 3340 AlphaEE XA EN

6 Pages

-

A 1732 DC EVSE Adapter EN

2 Pages

-

MI 3114 PV Tester EN

2 Pages

-

MI 3215 TeraOhmHP 15 kV EN

2 Pages

-

MI 3211 TeraOhmHP 10 kV EN

2 Pages

-

MI 3115 PV Analyser EN

2 Pages

-

MI 3132 EV Tester EN

3 Pages

-

MI 3365 25A OmegaEE XD EN

8 Pages

-

MI 3365 F OmegaEE XD EN

8 Pages

-

MI 3365 M OmegaEE XD EN

8 Pages

-

MI 3365 OmegaEE XD EN

8 Pages

-

MI 3360 OmegaGT XA guide EN

56 Pages

-

MD 9210 Mini Clamp Meter EN

2 Pages

-

Medical Facilities catalogue

64 Pages

-

Building Facilities catalogue

72 Pages

-

General catalogue 2023 EN

272 Pages

-

MI 3299 HV demo BOX

1 Pages

-

SW 1203 Metrel SDK EN

3 Pages

-

MI 3360 OmegaGT XA EN

4 Pages

-

MI 3325 MultiServicerXD EN

4 Pages

-

MI 3394 CE MultiTesterXS EN

2 Pages

-

MI 3394 CE MultiTesterXA EN

3 Pages

-

MI 6601 MediTest EN

4 Pages

-

MI 3110 EurotestIM EN

2 Pages

-

A 1722 PRCD adapter EN

2 Pages

-

A 1632 eMobility Analyser EN

2 Pages

-

A 1532 XA EVSE adapter EN

2 Pages

-

A 1532 EVSE adapter EN

2 Pages

-

MI 2093 Line Tracer EN

2 Pages

-

MI 3109 EurotestPV Lite EN

2 Pages

-

MI 3108 EurotestPV EN

2 Pages

-

MI 3125 BT EurotestCOMBO EN

2 Pages

-

MI 3125 EurotestCOMBO EN

2 Pages

-

MI 3100 SE EurotestEASI EN

2 Pages

-

MI 3102 BT EurotestXE EN

2 Pages

-

MI 3143 Euro Z 440 V EN

2 Pages

-

MI 3144 Euro Z 800 V EN

2 Pages

-

MI 3202 GigaOhm 5 kV EN

2 Pages

-

MI 3201 TeraOhm 5 kV Plus EN

2 Pages

-

MI 3311 GammaGT EN

2 Pages

-

MI 3309 BT DeltaGT EN

2 Pages

-

MI 3242 MicroOhm 2A EN

2 Pages

-

MI 3250 MicroOhm 10A EN

2 Pages

-

MI 3252 MicroOhm 100A EN

2 Pages

-

MI 3281 WR Analyser EN

2 Pages

-

MI 2891 Power Simulator EN

2 Pages

-

MI 2883 Energy Master EN

4 Pages

-

MI 2885 Master Q4 EN

4 Pages

-

MI 2884 Energy Master XA EN

4 Pages

-

MI 2892 Power Master EN

4 Pages

-

MI 2893 Power Master XT EN

4 Pages

-

MI 3205 TeraOhmXA 5kV EN

2 Pages

-

MI 3210 TeraOhm XA 10kV EN

2 Pages

-

Metrel application catalogue

28 Pages

-

MI 3155 EurotestXD EN

4 Pages

-

MI 3209 TeraOhmLT 10kV EN

2 Pages

-

MI 3102 BT EurotestXE

2 Pages

-

MD 9930 Thermal camera EN

2 Pages

-

MI 3280 DT Analyser EN

2 Pages

-

MI 3290 Earth Analyser EN

4 Pages

-

MI 3152 EurotestXC EN

2 Pages