Website:

Metalnastri

Website:

Metalnastri

Group: Metalnastri

Catalog excerpts

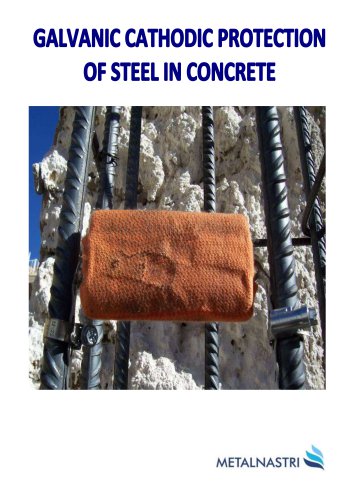

The product Zinc-o-fix® consists of a high pureness zinc-tape (> 99, 95% of the chemical mass of zinc) with a nominal thickness of 0,08 mm. This tape is supplied with a > 0.025 mm thick adhesive, which can resist continuous operating temperature of 80° C and which reacts under electro-conductive pressure. The adhesive layer is covered by a siliconised paper, which protects the band from getting damaged or polluted until the tape is applied. The product is available in two forms: • in shapes, based on the client's needs • in rolls, whose width and length are shown in the table below Zinc-o-fix® is designed to cover the surface of iron, steel, aluminium and light metals in order to protect them from corrosion. This is achieved by pressing it on the surface that needs to be protected from corrosion. This method is commonly known as "Laminar Zinc Coating" The adhesive coat, which is applied only on one side of the Zinc-o-fix®, consists of a matrix of adhesive and a percentage of zinc powder. Through the addition of zinc powder, we have achieved the most important effect, which is making the adhesive itself electro conductive. This process allows the adhesive to create an electrical couple between the surface that needs to be protected and the Zinc-o-fix®, so that the zinc can act as galvanic anode. Zinc Granules The enlargement on the right shows the application of our Zinc-o-fix® on a steel surface. It can be seen that the thickness of the adhesive layer always remains the same and that the zinc granules are dispersed evenly throughout the adhesive layer. These granules are necessary to enable the adhesive to be electro-conductive and to assure a continuous metallic contact between zinc and steel. Steel Electro-conductive adhesive As a consequence of the unique manufacturing process and the high pureness of the employed zinc, the band has an absolutely homogeneous and isotropic microstructure, which cannot be found in other protection systems. For this reason, any pitting or any form of local corrosive attacks are avoided. Therefore, we can state that, owing to the following features: • stopping any direct corrosion; • active anticorrosive protection thanks to the electrical contact between the surface to be protected and the zinc layer, which, in the presence of an electrolyte, reacts as a sacrificial anode; • presence of an adhesive layer, anchored on the surface to be protected, which is an additional defense against corrosion. The coating with our zinc layer assures a cathodic protection of metallic surfaces for a time that, in most cases, is equal or longer than the lifetime of the structure to be protected. Cathodic Protection The picture on the right shows the difference between two iron bars held in a salt and water solution for one year. A 50 mm Zinc-o-fix® coated one of the two bars on its central area. The role played by Zinc-o-fix® as a sacrificial anode is of great importance: although its coating covers only one area of the structure, Zinc-o-fix® protects the whole surface against corrosion. The zinc tape must be stuck to the nobler metal. Should there be doubts concerning the electrolytic potentials of the materials, it is advisable to cover both the surfaces with the Zinc-o-fix®, so that any corrosion attack can be avoided.

Open the catalog to page 1

Coupling steel – Light Alloy The point of contact between light alloys and iron materials can be subjected to corrosion. When these two materials get in both electrical and electrolytic contact, a galvanic process begins. The electrolytic contact arises when a solution (usually rainwater) seeps between the two surfaces. This contact can even be caused by signs of dampness between the two surfaces or by a chemical non- homogeneity of one of the two surfaces because of the presence of oxides, dirt, etc. Since the electrochemical potentials of steel and iron materials are more electropositive...

Open the catalog to page 2All Metalnastri catalogs and technical brochures

-

zincofix durability

2 Pages

-

BIOZINC - EN

3 Pages

-

DOUBLESHIELD - EN

3 Pages

-

ROLLANODE - EN

1 Pages

-

ZincTape

6 Pages