Catalog excerpts

Product Description Metallisation Sprayseal F and Sprayseal C are ready to use 1-component, air curing, permeation sealers based on a special polymeric formulation. They can be applied by brushing, spraying, rolling or dipping to permeate throughout the coating thickness. Sprayseal F fills fine cavities and pores of up to 0.1 mm whilst Sprayseal C fills coarse cavities and pores from 0.1 mm to 0.5 mm. Sealing throughout the coating is guaranteed by the extremely searching capillary properties of the formulation. Coating compressive strength is increased by sealing. PREPARATION The spray surface must be clean and free of contamination and dust. APPLICATION Apply directly to the as sprayed coating before machining. The component temperature should not exceed 30°C to guarantee complete permeation of the sealers. SPRAY, BRUSH OR ROLLER Apply Sprayseal F / C in up to 4 passes 1 minute intervals. DIPPING Place Sprayseal F / C in a clean container. Submerge components in the sealer for approximately 5 minutes. Remaining sealer can be poured back into the container for storage and reuse. Application Methods Roller. Dipping. Properties Capillary-active permeation of micropores, voids and cracks up to ~0.5 mm. Application without vacuum or pressure. Excellent coverage and paintability. Improved corrosion protection. Approvals for use with food and drinking water. Sprayseal F / C cures at room temperature (approximately 1 hour per millimetre of coating thickness) by the evaporation of the volatile components of the sealer. Because of their quick drying properties, components are touch dry and usable in around 10 minutes. METALLISATION guarantees product characteristics, as long as Sprayseal is stored according to the instructions detailed in this data sheet. METALLISATION is not responsible for the processing and handling of the material. If you have further questions, please contact our technical team. Please read the information clearly before using the product Fast drying at room temperature. High pressure resistance Package Size Shelf Life 12 months in sealed container; store cool and dry.

Open the catalog to page 1

SPRAY SEAL-F SPRAY SEAL-F-SP SPRAY SEAL-C SPRAY SEAL-C-SP Fine porosity Fine porosity aerosol spray Coarse porosity Coarse porosity aerosol spray Fully Cured Touch Dry Machinable Cure Time Fully Cured Viscosity Surface Layer Thickness Versatility Spraying: Spray 3-4 times in one minute intervals on the surface to guarantee the best possible permeation. Brushing: Brush 3-4 times in one minute intervals on the surface to guarantee the best possible permeation. Dipping: Submerge components in the Sprayseal for approximately 5 minutes. Ensure remaining Sprayseal is poured back into the...

Open the catalog to page 2All Metallisation catalogs and technical brochures

-

ARC1020

13 Pages

-

ARC145/150-RC

15 Pages

-

Arcspray 150(19)

15 Pages

-

Arcspray 150P

15 Pages

-

Arcspray 145(19)

15 Pages

-

Arcspray 145P

15 Pages

-

Arcspray 528E(16)-ICC

1 Pages

-

Arcspray 701(16)-CL

1 Pages

-

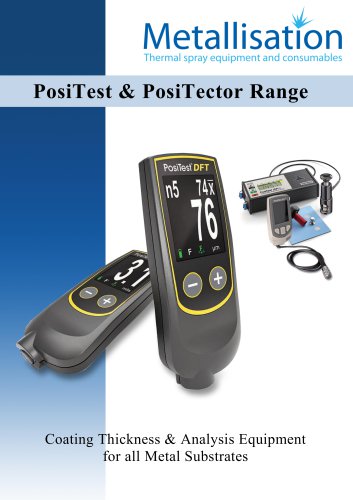

Positector and Positest-AT

4 Pages

-

Helmet RPB

4 Pages

-

MET-CLAD

1 Pages

-

Met-PCC(PLAS)

1 Pages

-

MK61-FS Wire Flame

1 Pages

-

MK73-FS Wire Flame

1 Pages

-

Arcspray 150/S500(16)-CL

1 Pages

-

Arcspray 145/S345-CL

1 Pages

-

Arcspray 145/S245-CL

1 Pages

-

Arcspray 170AC-CL

1 Pages

-

Arcspray 150/S500-CL

1 Pages

-

Flamespray MK73-FS

1 Pages

-

PISTOL CONTROL CONSOLE

2 Pages

-

PLASMA PS50M-PC

1 Pages

-

HVOF METJET 4L

1 Pages

-

Arcspray 528E-ACD

1 Pages

-

Arcspray 528E-ICC

1 Pages

-

Arcspray 170-CL

1 Pages

-

Arcspray 701-CL

1 Pages

-

Arcspray 340-PLC

1 Pages

-

Arcspray 140/S350-CL

1 Pages

-

Arcspray 140/S250-CL

1 Pages

-

MK74 Powder Flame

1 Pages

-

MK66E-M Wire Flame

1 Pages

-

MK66E-PC Auto Flame

1 Pages

-

MK61 Wire Flame

1 Pages

-

MK73 Wire Flame

1 Pages