Catalog excerpts

Thermal spray equipment and consumables Laser cladding equipment is a new product/process to be offered by Metallisation in 2014. Laser cladding falls into the group of processes commonly known as hard facing. The laser cladding process is a method of applying a fully dense, metallurgically bonded and virtually pure coating which can be used to increase the wear resistance, corrosion resistance or impact performance of metallic components. In some cases, all three of these properties can be improved. The process utilizes a precisely focused, high power laser beam to create a weld pool into which a metallic powder is applied. The highly accurate nature of the the laser beam allows fully dense cladding with minimal dilution (typically <5%) yet with a perfect metallurgical bond. The MET-CLAD system offers a neatly packaged control system for the integration and operation of the laser, process gases, coolant and powder feed. The touch screen HMI provides an intuitive interface for the operator to control the entire cladding process. The system can be manually controlled or automatic recipes can be programmed for repeat jobs. The system also integrates into robot/automation and other peripherals like CCTV cameras in the cladding booth. A 3kW laser can be offered in a 19” rack (as pictured) or larger, separate lasers can be interfaced. Metallisation's 90+ experience in the thermal spray industry now extends to offer support of this new process. Either the basic unit as shown can be supplied or full turnkey packages with cladding training and consultancy are available. Diode laser with 5 yr warranty on Easy to operate Mass flow process gases and powder feed Unlimited recipes and parameter recording Dense, fully bonded coatings with low dilution Low running costs vs PTA Typical Applications: Down hole stabilisers High temp process rolls in the steel industry ■ Coal/ore crushing hammers ■ Waste incineration boiler ■ Valve balls/seats ■ Hydraulic rods All figures are approximate and offered as guidance only. Performance may vary depending on application and parameters.

Open the catalog to page 1All Metallisation catalogs and technical brochures

-

ARC1020

13 Pages

-

ARC145/150-RC

15 Pages

-

Arcspray 150(19)

15 Pages

-

Arcspray 150P

15 Pages

-

Arcspray 145(19)

15 Pages

-

Arcspray 145P

15 Pages

-

Arcspray 528E(16)-ICC

1 Pages

-

Arcspray 701(16)-CL

1 Pages

-

SPRAYSEAL-F

2 Pages

-

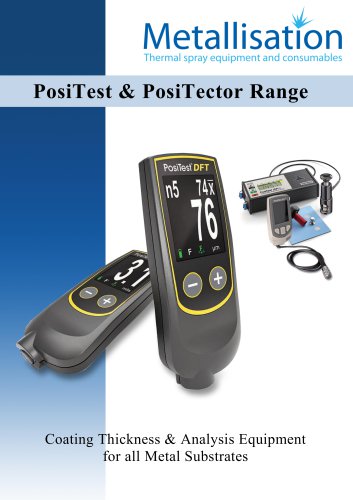

Positector and Positest-AT

4 Pages

-

Helmet RPB

4 Pages

-

Met-PCC(PLAS)

1 Pages

-

MK61-FS Wire Flame

1 Pages

-

MK73-FS Wire Flame

1 Pages

-

Arcspray 150/S500(16)-CL

1 Pages

-

Arcspray 145/S345-CL

1 Pages

-

Arcspray 145/S245-CL

1 Pages

-

Arcspray 170AC-CL

1 Pages

-

Arcspray 150/S500-CL

1 Pages

-

Flamespray MK73-FS

1 Pages

-

PISTOL CONTROL CONSOLE

2 Pages

-

PLASMA PS50M-PC

1 Pages

-

HVOF METJET 4L

1 Pages

-

Arcspray 528E-ACD

1 Pages

-

Arcspray 528E-ICC

1 Pages

-

Arcspray 170-CL

1 Pages

-

Arcspray 701-CL

1 Pages

-

Arcspray 340-PLC

1 Pages

-

Arcspray 140/S350-CL

1 Pages

-

Arcspray 140/S250-CL

1 Pages

-

MK74 Powder Flame

1 Pages

-

MK66E-M Wire Flame

1 Pages

-

MK66E-PC Auto Flame

1 Pages

-

MK61 Wire Flame

1 Pages

-

MK73 Wire Flame

1 Pages