Catalog excerpts

MolyCom® HOT ALONE WON’T DO THE TRICK Molybdenum disilicide (MoSi2) electric heating elements up to 1820 °C (3308 °F) element temperature MolyCom®-Ultra and MolyCom®-Hyper electric heating elements are metallic-ceramic materials mainly composed of molybdenum disilicide (MoSi2). Above 1000 °C service temperature the surface will form a protective high-temperature layer of pure quartz, which gives the MolyCom® heating elements a high resistance to oxidation. The elements may be used up to a surface temperature of maximum 1820 °C in oxidizing atmospheres. These elements are manufactured according to established industry standards. Long service life and easy replacement contribute to high furnace utilization and low maintenance costs. The surface of the element will form a selfregenerating protective layer in oxidizing atmosphere. That makes them suitable for aggressive atmospheres. For even specific process atmospheres we provide heating elements with a thicker SiO2 layer. CARABIN CREATIVES | corporate + digital solutions New and old elements can be used together and in series. The elements can also be used in combination with other molybdenum disilicide elements as an alternative or replacement part, because the element’s wearout affects the performance only slightly. Whether industrial standard, high-purity demands or special resistance to oxidation – SCHUPP® Ceramics makes high temperature technology to suit your specific requirements. MolyCom®-Ultra 1700, 1800 and 1850 are particularly durable and conform to industrial standards. CARABIN CREATIVES | corporate + digital solutions MolyCom®-Hyper heating elements are composed of high-purity raw materials. Trace elements are reduced to a minimum (1/10 compared to competitor) which makes them suitable for high purity sophisticated demands. Therefore the heating elements show an excellent low temperature oxidation (“pest”) resistance and long life use. MolyCom®-Hyper 1800 and MolyCom®-Hyper 1800SC (Super Clean) allow sintering of zirconia without discolouration, also above 1600 °C. MolyCom®-Hyper 1800AP (Anti Pest) is a special type of element, one that is resistant to oxidation from 200 °C to 700 °C. YOUR BENEFITS WITH MOLYCOM® AT A GLANCE MolyCom®-Ultra – Industrial Standard High surface load and long service life U-, L-, W-shaped elements and other geometries Diameters from 3/6 mm to 12/24 mm and lengths M.E. SCHUPP Industriekeramik GmbH Neuhausstraße 4-10, 52078 Aachen/Germany Tel.: +49 (0) 241 -93677-0 Fax:

Open the catalog to page 1

MolyCom®-Ultra and -Hyper heating elements are manufactured by the Powder-Metallurgy-Technology. They are made in U-, W- and L-shapes, diameters 3/6 mm, 4/9 mm, 6/12 mm, 9/18 mm, 12/24 mm and in total length up to about 2000 mm and more. MolyCom® products are precisely manufactured and hot bended. * Also available as MolyCom®-Hyper 1800, MolyCom®-Hyper 1800SC and MolyCom®-Hyper 1800AP with a maximum length of Le with 650 mm and Lu with 500 mm.

Open the catalog to page 2

AVAILABLE STANDARD TYPES OF HEATING ELEMENTS U-Shape AVAILABLE SPECIAL TYPES OF HEATING ELEMENTS Rod-Type Other types upon request.

Open the catalog to page 3

AVAILABLE ACCESSORIES FOR MOLYCOM® HEATING ELEMENTS CONTACT STRAPS Martin Braun Fotografie – www.braun-foto.com Power-to-Power Power-to-Element Element-to-Element HOLDERS Single-shank holders Two-shank holders All necessary accessories like contact straps, single- and two-shank holders, air nozzles and passage bricks are available.

Open the catalog to page 4All M.E.SCHUPP Industriekeramik GmbH catalogs and technical brochures

-

PTCR WEB APP

1 Pages

-

PTCR Micrometer

2 Pages

-

MolyCom® Accessories

13 Pages

-

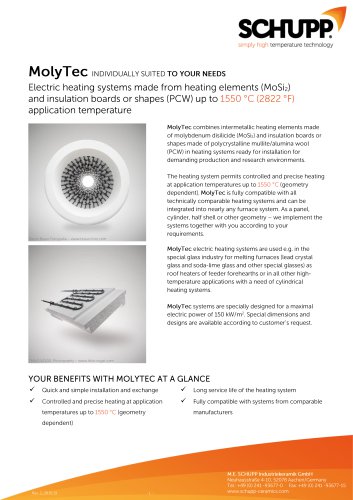

MolyTec

2 Pages

-

ITM-Fibermax®

2 Pages

-

PTCR

4 Pages

-

UltraVac

2 Pages

-

UltraBoard EU

2 Pages

-

FiberPlast C1800 D

2 Pages

-

Company Broschure

11 Pages