Catalog excerpts

simply high temperature technology HIGH TEMPERATURE METALLIC-CERAMIC ^ PRODUCTS, COMPONENTS AND SYSTEMS FOR ELECTRICALLY AND COMBUSTION-HEATED ^ FURNACES 1 HEATING | INSULATION | MEASURING

Open the catalog to page 1

YOUR APPLICATION ANWENDERINDUSTRIEN | 3 INDUSTRIES 2 |WE APPRECIATE TECHNOLOGY ANWENDERINDUSTRIE AND COMPETITION, HUMANITY AND TRADITIONAL & INNOVATIV TEAMWORK, TRADITION AND INNOVATION. HEAT TREATMENT SINTERING & FIRING PROFESSIONAL AND COMPETITIVE HIGH TEMPERATURE TECHNOLOGY SCHUPP® Ceramics is an established specialist for we provide standard and tailor-made solutions for high temperature technology. Our family-owned industrial applications, production and research for company has been developing, producing and customers around the world. marketing high-quality metallic-ceramic solutions...

Open the catalog to page 2

ADDING VALUE BY VALUING OTHERS Flexibility and determination characterise how we meet our customers‘ requirements. Our international team of more than 50 employees are focused on assisting more than 900 customers worldwide. Trust, honesty and the will to make a difference define how we establish and maintain successful partnerships. In keeping with the principle adding value by valuing others, we cultivate our relationships with customers, production and research partners and employees. Similarly, it is understood that we handle materials and energy as responsibly and sparingly as possible....

Open the catalog to page 3

ANWENDERINDUSTRIEN | 7 ANDREI LOSCUTOV COMMERCIAL DIRECTOR MANFRED HERWEG TECHNICAL DIRECTOR EXPERTISE AND EXPERIENCE IN HIGH TEMPERATURE TECHNOLOGY SALES ARE A MATTER OF TRUST We develop customised, high temperature systems and reduce your costs. Our systems, components We trust our customers and we want them to trust practical measures. At the same time, creativity is as that successfully integrate into our customers‘ and products are built with knowledge gained from us. That‘s why we rely on fair pricing, as well as much a matter of course as our claim that we will thermal processes,...

Open the catalog to page 4

UltraBoard & UltraVac Efficient thermal insulation up to 1800 °C POLYCRYSTALLINE MULLITE/ALUMINA WOOL AND NEEDLED BLANKETS ITM-Fibermax® is the flexible thermal insulation Blankets needled on both sides are an indispensable variant – whether as a raw material in the form of component in module production. They have an wool and needled blankets. The material is an alumina content of 72 %. We offer densities of extremely good substitution for materials containing ceramic fiber. The light, shot- and ceramic fibre-free material is particularly suitable for temperatures above 1250 °C as well as...

Open the catalog to page 5

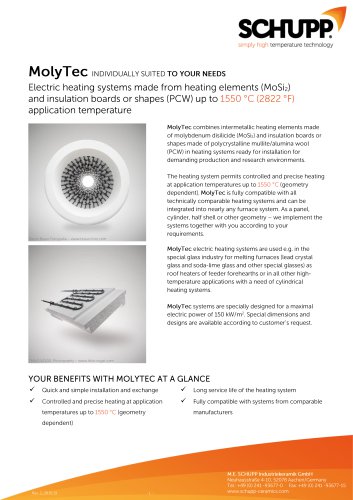

Electric heating and thermal insulation up to 1550 °C Insulation boards, cylinders and shapes for your furnace lining up to 1800 °C CUSTOMISED ELECTRIC HEATING SYSTEMS AND FURNACE LININGS MolyTec combines intermetallic molybdenum disilicide (MoSi2) heating elements and polycrystalline mullite/ offer the appropriate electric heating elements (MoSi2) alumina wool (PCW) shaped insulation parts to make upon request – all from one source. Development, Our service: consulting, conception, turn-key heating systems for sophisticated areas like planning and installation of both versions is always...

Open the catalog to page 6

INDUSTRIAL STANDARD MolyCom®-Ultra 1700, 1800 and 1850 HIGH PURITY Complex heating element geometries INTERMETALLIC MOLYBDENUM DISILICIDE HEATING ELEMENTS (MoSi2) SC - Super Clean AP - Anti Pest Whether industrial standard, high-purity demands or special resistance to oxidation – SCHUPP® Ceramics ·· MolyCom -Ultra – Industrial Standard trace elements are reduced to a minimum (1/10) ·· Up to 1820 °C element temperature; up to 1750 °C application temperature specific requirements. of element, one that is resistant to oxidation from MolyCom -Ultra 1700, 1800 and 1850 are particularly...

Open the catalog to page 7

Process Temperature Control Rings PTCR Universal, precise control of thermal processes from 560 °C up to 1750 °C ANWENDERINDUSTRIEN | 15 CERAMIC ADHESIVE FOR HIGH TEMPERATURE APPLICATIONS MADE OF POLYCRYSTALLINE MULLITE/ALUMINA WOOL (PCW) SCHUPP® Ceramics offers a reliable solution for added inorganic binders and specifically coordinated connecting high temperature parts as well: FiberPlast C 1800 D permits reliable bonding or We will gladly develop special high temperature coating of ceramic fibre-based materials - such as masses, such as adhesives or coatings, together with insulation...

Open the catalog to page 8

VASILEIOS POURDAS ANWENDERINDUSTRIEN | 17 WAREHOUSE & LOGISTICS MANAGER DR. KATARZYNA FALENTY INNOVATION & TECHNOLOGY MANAGER QUALITY MANAGEMENT IS TEAMWORK LOGISTICS IS MORE THAN JUST TRANSPORTATION We want to help your company succeed, this is how everyone in the team always strives to optimise the The reliable integration of our systems, components the success of our customers‘ production, particularly we measure the value of our work. results from development to practical and products into your supply chain is important to in dynamic and complex markets. This is why we have developed a...

Open the catalog to page 9

All technical data sheets are available on www.schupp-ceramics.com. UltraBoard & UltraVac

Open the catalog to page 10

M.E. SCHUPP Industriekeramik GmbH NeuhausstraBe 4-10 52078 Aachen/Germany Telephone: +49 (0) 241-93677-0 Fax: +49 (0) 241-93677-15 E-Mail: info@schupp-ceramics.com Detailed information can be found on our website: www.schupp-ceramics.com V_03.E.12.2018 Design: CARABIN CREATIVES | Portraits & Products: THILO VOGEL Photography | Group Portrait: STADTBILD Renate Schutt

Open the catalog to page 11All M.E.SCHUPP Industriekeramik GmbH catalogs and technical brochures

-

PTCR WEB APP

1 Pages

-

PTCR Micrometer

2 Pages

-

MolyCom® Accessories

13 Pages

-

MolyCom®

4 Pages

-

MolyTec

2 Pages

-

ITM-Fibermax®

2 Pages

-

PTCR

4 Pages

-

UltraVac

2 Pages

-

UltraBoard EU

2 Pages

-

FiberPlast C1800 D

2 Pages