Catalog excerpts

Optimise your processes and increase your quality Quality assurance systems for slab and hot strip

Open the catalog to page 1

perfecting your performance EMG Strip guiding solutions The company EMG is the specialist when it comes to intelligent and complex automation solutions. As a technology leader, EMG is the first point of contact for you, our customers. Central areas of application for series products, individual components and complex system solutions from EMG are continuous production processes in the metal industry. As a traditional company and world market leader with 75 years of experience, EMG’s Metals business unit offers its customers, i.e. you, complete solutions for your respective individual...

Open the catalog to page 2

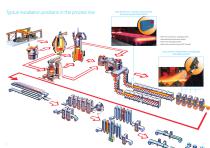

Typical installation positions in the process line Slab dimension / position measurement and tracking with EMG iSCAN® » after the continuous casting process (conventional continuous caster) » before the heating furnace » before the tunnel furnace (CSP® plants) Strip position measurement and guiding with EMG hotCAM

Open the catalog to page 3

Slab dimension measurement Width, length and thickness - with EMG iSCAN® the non-contact and precise measurement of the slab geometry is realised. The number, type and configuration of the laser-based sensors are adapted to your individual application. Measuring accuracy* As far as technically possible, the laser sensors required for the application have laser protection class 2. Our sensors are ideally suited for harsh environmental conditions, e.g. high temperatures. Slab positioning & tracking Further areas of application of EMG iSCAN® are the slab tracking on the roller table from the...

Open the catalog to page 4

Position measurement The hot rolling process is typically a combination of a reversing stand (roughing stand) and a finishing line with several rolling stands. Maintaining a defined position of the strip bet-ween the rolling stands is enormously important for process reliability in a hot rolling mill. The continuous measurement of the strip position with our EMG hotCAM solution enables you to optimise the adjustment of rolling force and gap. The measuring accuracy of our system is +/- 1.5 mm. reversing stands this leads to a reduction of the strip camber and thus to the avoidance of...

Open the catalog to page 5

Control algorithm with SMS X-Pact® Using the EMG hotCAM centre position, a closed control loop can be realised in a finishing line. EMG draws on the many years of experience of the SMS Group, which has developed the SMS X-Pact®, a product that demonstrably stabilises the rolling process. With this combination of position measurement on the hot strip EMG hotCAM and the closed control loop, EMG offers comprehensive process optimisation in the hot strip area. Advantages EMG hotCAM & SMS X-Pact® » Sheared strip ends are reduced » Fewer unscheduled roll changes necessary » Improvement of process...

Open the catalog to page 6

EMG Automation GmbH Industriestraße 1 57482 Wenden Germany T +49 2762 612-0 www.emg.elexis.group info@emg-automation.com © EMG / QA systems hot strip / EN / Rev 00 / 11.2022 / Printed in Germany / Subject to modification

Open the catalog to page 7All MESACON MESSELEKTRONIK GMBH DRESDEN catalogs and technical brochures

-

ELDRO

2 Pages

-

EMG iTiM

7 Pages

-

EMG iCAM®

6 Pages

-

EMG iSCAN®

8 Pages

-

EMG hotCAM

6 Pages

-

EMG SOLID®

8 Pages

-

eMASS®

8 Pages

-

Strip guiding systems Sensors

11 Pages