Catalog excerpts

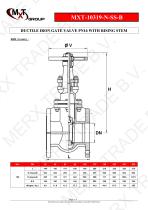

DUCTILE IRON GATE VALVE PN16 WITH RISING STEM DN 40 to DN 300 Flanges ISO PN16 R.F. - 10°C + 120°C 16 Bars Rising stem Stainless steel stem Brass seat Size : Ends : Min Temperature : Max Temperature : Max Pressure : Specifications : Materials : Ductile iron body Information provided as an indication and subject to possible modification

Open the catalog to page 1

DUCTILE IRON GATE VALVE PN16 WITH RISING STEM Ductile iron body flanged R.F. ISO PN16 Ref. 10319 from DN 40 to DN 300 LEAKAGE RATE ( WITH WATER AT 20°C ) : TORQUE VALUES ( Nm without safety coefficient ) : For common fluids Min and max Temperature Ts : - 10°C to + 120°C Max Pressure Ps : 16 bars Single wedge disc Graphite packing Rising stem Stainless steel stem Brass seat Flanges R.F. ISO PN16 Painting RAL 7011 grey color, 90 µm thickness Information provided as an indication and subject to possible modification

Open the catalog to page 2

DUCTILE IRON GATE VALVE PN16 WITH RISING STEM Body seat Wedge Wedge seat Bonnet gasket Packing gland Information provided as an indication and subject to possible modification

Open the catalog to page 3

DUCTILE IRON GATE VALVE PN16 WITH RISING STEM Information provided as an indication and subject to possible modification

Open the catalog to page 4

DUCTILE IRON GATE VALVE PN16 WITH RISING STEM DIRECTIVE 97/23/CE : CE N° 0038 Risk Category III module H Length according to EN 558 series 14 ( DIN 3202 F4 ) ADVICE : Our opinion and our advice are not guaranteed and MXT shall not be liable for the consequences of damages. The customer must check the right choice of the products with the real service conditions. Information provided as an indication and subject to possible modification

Open the catalog to page 5

DUCTILE IRON GATE VALVE PN16 WITH RISING STEM INSTALLATION INSTRUCTIONS Before installing the valves,clean and remove any objects from the pipes (in particular bits of sealing and metal) which could obstruct and block the valves. INSTALLATION INSTRUCTIONS : Ensure that both connecting pipes either side of the valve (upstream and downstream) are aligned (if they’re not,the valves may not work correctly). Make sure that the two sections of the pipe (upstream and downstream) match,the valve unit will not absorb any gaps.Any distortions in the pipes may affect the thightness of the...

Open the catalog to page 6All MerxTrade BV catalogs and technical brochures

-

MXT-13950000

1 Pages

-

Check-Valve-Swing-Thread

5 Pages