Catalog excerpts

CURRENT COLLECTION TECHNICAL GUIDE Contact strips

Open the catalog to page 1

I ntro duction: What is C u rr e nt Co lle ction ? p. 3 Curr ent Collection u sing Panto grap h syst e m s p. 4 Grade selection for Overhead Current Collection p.5 lV ow to select the correct grade for a carbon strip? p.6 Current to be collected p.6 Operating linear current density p.6 Current at standstill p.7 lM ersen grades for overhead Current Collection p.8 lW hy is there a limit to copper content? p.9 lW hy the need for low temperature? p.9 Contact strip designs p.10 Contact strip Service Life time p.11 l Curr ent Collection u sing T hir d or Fo u rth R ail p.12 Characteristics of...

Open the catalog to page 2

What is C urrent Collection ? Electric locomotives, metros and tramways need electric power to move. Power transfer has to be safe and reliable, both in stationary mode for auxiliary power and for motive power when moving. Transmission of power is done by either an overhead wire or by rails at ground level. AC systems always use overhead wires, DC systems can use either an overhead wire or a third rail. There are 2 types of current collectors: Pantograph Systems lR ailways (electric locomotives, Electrical Multiple Units) lT ransit systems (light rail, tramways, some metros) © Leonid...

Open the catalog to page 3

C urrent C ollection using Pantogra p h s y stems 4 The electricity required to power the electric traction motors is collected by means of a pantograph running on a catenary. A catenary is a system of overhead wires used to supply electricity to an electric unit, such as an electric locomotive or an Electrical Multiple Unit (EMU), which is equipped with a pantograph. A pantograph is a system of articulated arms fixed on the roof of the locomotive. It unfolds and extends along a vertical axis. Its role is to transfer power from the contact line to the electric traction unit. The principal...

Open the catalog to page 4

G rade selection f or O verhead C urrent C ollection 5 VOLTAGE FAMILIES High Voltage AC l2 5 kV @ 50 or 60 Hz l 1 5 kV @ 16.7 Hz High speed Example of the distribution of the two voltage families in Europe: Mainly pure carbon grades will be used Impregnated grades can be used on poor quality catenary systems. Low Voltage DC High Voltage AC High speed Metal-graphite or metal-impregnated grades will be used Some older, heavy freight locomotives use pure copper strips which are gradually being replaced by metal impregnated carbon. Copper catenary Network voltage (Voltage available between...

Open the catalog to page 5

HOW TO SELECT THE CORRECT GRADE FOR A CARBON STRIP? 6 The first parameter to consider is the current to be collected The current to be collected depends on locomotive power and network voltage. ! When voltage is low, current is high Power of the locomotive (W) = Network Voltage (V) The power of the locomotive is a fixed value, therefore: l Higher voltage will mean lower current l Lower voltage will mean higher current Either we calculate current to be collected using above formula, or in most cases this value is given in the specifications supplied by the customer. Current is one of the...

Open the catalog to page 6

HOW TO SELECT THE CORRECT GRADE FOR A CARBON STRIP? A key parameter for grade selection, the operating linear current density j per contact strip: Calculation of j for your specific situation j is calculated by the following formula: j Permanent linear current density for the strip (A/mm) n Current distribution factor n = 1 if 1 strip per pantograph n = 0.6 if 2 strips per pantograph n = 0.4 if 3 strips per pantograph n = 0.3 if 4 strips per pantograph k Catenary factor k = 1 if single catenary k = 1.5 if double catenary Ip Permanent running current per pantograph (A) w Width of the strip...

Open the catalog to page 7

MERSEN GRADES FOR OVERHEAD CURRENT COLLECTION 8 Each carbon grade was created to withstand a maximum operating linear current density. To select the right grade, one has to consider the permanent linear current density (j), and choose a grade with a jmax value at least equal to j. Recommended jmax values for each Mersen grade are tabulated below (Column "Maximum operating linear current density"). Mersen has developed a wide range of carbon grades to meet even the most demanding operating conditions. We recommend that our customers contact our Customer Technical Assistance to correctly...

Open the catalog to page 8

Why is there a limit to copper content? The copper content is limited by customers' technical constraints: lT he maximum contact strip weight to ensure pantograph dynamic stability and minimal arcing lT he maximum temperature at standstill conditions (see hereafter why low temperature is required) These two requirements are contradictory To limit the weight of the contact strip, the density of the impregnated carbon must be low To limit the temperature of the catenary, the resistivity of the impregnated carbon must be low Low copper content rate High copper content rate WHY THE NEED FOR LOW...

Open the catalog to page 9

C ontact stri p designs A contact strip consists of a carbon or metal profile mounted on a supporting carrier. The carrier's role is to support the carbon strip mechanically, to resist deflection and to conduct the current. The carrier can be made of aluminium, galvanised steel or copper to resist atmospheric attack and impact damage. To be noted! Soldered carbon strip Our current collection bonded strips are DIN6701-2 certified (German standard specific to the adhesive bonding of components used on rail vehicles). l Copper electrolytic treatment to facilitate soldering Bonded carbon strip...

Open the catalog to page 10

C ontact stri p S ervice L i f e time 11 The wear of the contact strips is influenced by three factors: l Electrical (wear is mostly electrical) l Mechanical l Environmental Life time can also be influenced by: lP antograph and pantograph head design l Contact strip design Electrical factors Mechanical factors l Brake current feeding back l Pressure l Catenary pitch l Condition of the catenary wire l Construction of rail foundation l Mixed operation with metal strips Electrical wear Mechanical wear Environmental factors l Environment (ambient temperature, humidity, ice / hoarfrost, salt...

Open the catalog to page 11All Mersen Power Transfer Technologies catalogs and technical brochures

-

RAILWAYS & TRANSIT

2 Pages

-

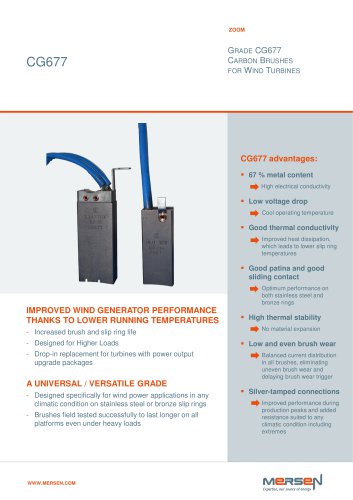

CG677

2 Pages

-

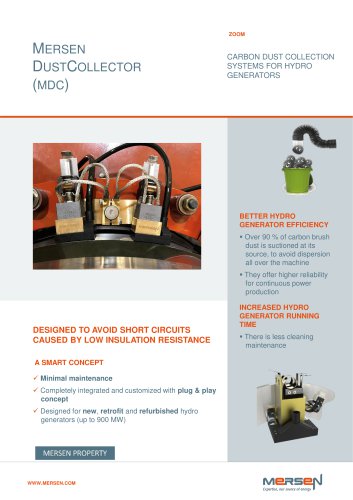

CURRENT COLLECTOR DEVICE

4 Pages

-

SURGE PROTECTION SOLUTIONS

24 Pages

-

TRANSPORTATION RAILWAYS

6 Pages

-

TRACTION AND TRANSIT

2 Pages

-

performance by mersen

20 Pages

-

BOOSTEC® SiC

9 Pages

-

PRODUCT CATALOG

348 Pages

-

BRUSH GEAR SYSTEMS

5 Pages

-

MERSEN OEM WIND SOLUTIONS

2 Pages

-

BOOST HCl ACID CONCENTRATION

1 Pages

-

ULTIMATE HCl ABSORBER

1 Pages

-

EcoDesign 3rd rail shoes

2 Pages

-

Current Collection

32 Pages

-

Ski lifts

2 Pages