Catalog excerpts

PROCESS INDUSTRIES / TRANSPORTATION /ENERGY Expertise, our source of energy W

Open the catalog to page 1

Carbon brus h grades p. 9 Main carbon brus h shapes , dimensions and hardware p.1 8 Recommendations for insta lling carbon brushes in mac hines p.22 Visual guide to slip ring / commutator films p. 24 How to order carbon brus hes? p.31 The specifications or data contained in present catalogue are only given for information and do not create any undertakings whatsoever. Any copy, reproduction or translation, either partially or fully, of these information is subject to the Mersen’s prior written consent. In addition, due to the continuing improvement of techniques and change of applicable...

Open the catalog to page 2

What is a carbon brush ? ( a l so ca l led “motor brush” ) A carbon brush is a sliding contact used to transmit electrical current from a static to a rotating part in a motor or generator, and, as regards DC machines, ensuring a spark-free commutation. A carbon brush can be: l Made of one or more carbon blocks with one or more shunts / terminals Five brush grade families are used for brush manufacturing. Each of them corresponds to a specific requirement and has its own production process (see pages 9 to 17 of this guide). Operating parameters The carbon brush plays an essential part in the...

Open the catalog to page 3

FRICTION COEFFICIENT (CALLED “µ”) Carbon brush friction coefficient “µ” has to be low and stable over time to allow the carbon brush to work without overheating. “µ” has no fixed value. It is the result of many factors depending upon the carbon brush grade, speed, load, commutator (or slip ring) condition and environment. For a given carbon brush grade, it is not possible to indicate a precise “µ” value, only a magnitude. This is sufficient for most machine calculations or projects. “µ” friction coefficient calculation formula The “µ” friction coefficient is the relationship between T...

Open the catalog to page 4

Electrical parameters VOLTAGE DROP (OR CONTACT DROP) The voltage drop has to be moderate to avoid overheating and abnormal electrical loss which can damage the sliding contact. It also influences commutation and current distribution in between the carbon brushes. This is an important characteristic which depends on the carbon brush grade, electrical contact and film (which is a complex mix of metal oxides, carbon, and water, deposited on the slip ring or commutator). Interface layer Brush Film It is therefore to be expected that the contact drop is influenced by all the factors which may...

Open the catalog to page 5

DISTRIBUTION OF CURRENT IN THE BRUSH CONTACT SURFACE Current does not flow uniformly across the whole brush contact surface. It flows through a varying number of very small areas called contact spots. Ideally these contact spots are evenly distributed. This balance may be disrupted when the contact spots concentrate and decrease in number. The film will then show signs of grooving, bar marking, streaking, and electrical erosion, deteriorating over time. Various factors can cause this imbalance: l l l E xternal agents (dust, vapors, excessive humidity, temperature) U nsuitable brush grades...

Open the catalog to page 6

Water, the essential component of commutator or slip ring films, is supplied by ambient air. The film will form best in a humidity range of 8 to 15 g / m3 (0.008 to 0.015 oz/ft3) of air (See Technical Data Sheet TDS-17*). In very dry air, the film consists mostly of metal oxides, causing high friction and brush wear. These unfavorable conditions become critical when the absolute humidity rate falls below a threshold of 2 g / m3 (0.002 oz/ft3) of air. This may be the case for: • Aerospace and space industry, where machines are likely to operate in rarefied atmospheres at high altitudes •...

Open the catalog to page 7

The more abrasive the dust, the more harmful it is. Dust causes: • Grooving of commutators and slip rings • High brush wear • Carbon brush side gulling (see picture opposite), with brushes sticking in their holders • pollution of machines Dust grooves partly avoid these problems, but the best remedy is prevention, providing clean filtered air to the machines. In totally enclosed machines, where carbon dust is continuously recirculated, the same problems are likely to arise, with the possibility of polluting the machine and decreasing its insulation resistance. These machines should be...

Open the catalog to page 8

C arbon brush grades 9 As stated in this guide’s introduction, there are five main brush grade families, each with a distinct set of properties. Some of these groups are complemented by a subgroup of impregnated brush materials (please consult us to find out more about the specific properties of those special materials). The choice of the most suited brush grade depends on a large number of parameters linked to the machine itself as well as its environment. Choosing the brush grade that performs best for a specific application requires an in-depth knowledge of its working environment....

Open the catalog to page 9

How are our carbographitic brush materials manufactured? They are made from a mixture of coke and graphite powders, agglomerated — with pitch or resin. This powder is molded into blocks which are baked at high 10 temperature to convert the binder into coke. These materials are not Carbographitic brushes commutate well due to their high resistance and provide good polishing action, while maintaining moderate contact drop. As a result of their high temperature treatment, carbographitic brushes can withstand both high temperatures and variable loads. main applications • Machines with an older...

Open the catalog to page 10

ANTICORROSION EQUIPMENT (graphite tubes and blocks - heat exchangers] SIEVING (different grades) ISOSTATIC or UNIAXIAL COMPRESSION How are resin-bonded brush grades manufactured? powdered natural or artificial graphite is mixed with a thermo-setting resin. The mix is then pressed and polymerized at a suitable temperature. Carbon brushes with high to very high electrical resistance, contact drop, electrical loss, and mechanical strength, which have very good commutating and cleaning properties. They can also work at very low current densities. main applications • AC Schrage-type commutator...

Open the catalog to page 11All Mersen Power Transfer Technologies catalogs and technical brochures

-

RAILWAYS & TRANSIT

2 Pages

-

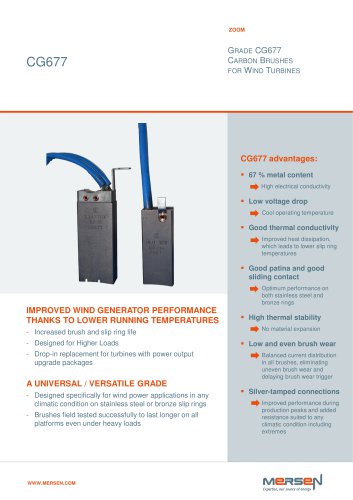

CG677

2 Pages

-

CURRENT COLLECTOR DEVICE

4 Pages

-

SURGE PROTECTION SOLUTIONS

24 Pages

-

TRANSPORTATION RAILWAYS

6 Pages

-

TRACTION AND TRANSIT

2 Pages

-

performance by mersen

20 Pages

-

BOOSTEC® SiC

9 Pages

-

PRODUCT CATALOG

348 Pages

-

BRUSH GEAR SYSTEMS

5 Pages

-

MERSEN OEM WIND SOLUTIONS

2 Pages

-

BOOST HCl ACID CONCENTRATION

1 Pages

-

ULTIMATE HCl ABSORBER

1 Pages

-

EcoDesign 3rd rail shoes

2 Pages

-

Current Collection

32 Pages

-

Ski lifts

2 Pages