Catalog excerpts

MeRseivI Expertise, our source of energy W BOOSTEC® SiC SILICON CARBIDE MATERIAL SOLUTIONS FOR SPACE, ASTRONOMY, LASERS PROCESSES, SEMICONDUCTOR & OPTO-MECHANICS OEMS AND CHEMICAL INDUSTRIES

Open the catalog to page 1

+OOSTEC® SiC An outstanding material Boostec®SiC is a polycrystalline technical ceramic of a SiC type, obtained by pressureless sintering. This process leads to a silicon carbide that is completely free of non-combined silicon. YOUNG'S MODULUS 420 GPa DENSITY 3.15 g/cm3 HIGH SPECIFIC STIFFNESS LIGHT WEIGHT MATERIAL HIGH MECHANICAL STRENGTH SINTERED SIC FREE OF NON-COMBINED Si HIGHLY HOMOGENEOUS CORROSION RESISTANT BOOSTEC® SiC Performance HIGH CHEMICAL RESISTANCE IN EXTREMELY CORROSIVE ENVIRONMENTS PERFECTLY ISOTROPIC HIGH THERMAL STABILITY MICROSTRUCTURE & PHYSICAL PROPERTIES PERFECTLY...

Open the catalog to page 2

W IT H ITS AI R BUS D EFEN C E AND SPAC E PA RTN ER SH I P, M E R SE N BOOSTEC I S TH E WO R L D LEA D ER FOR SiC SPAC E O PTI C S. Mersen Boostec provides SiC also SiC focal plane hardware for High specific stiffness telescopes to be used in space or EUCLID NISP INSTRUMENT – IMAGE COURTESY OF LAM mirrors, SiC stable structures and High thermal stability Qualification for space applications down to 30 K Application requests mechanical and thermal ultra-stable optics A W I D E R A N G E O F KO R S C H TELESCO PES FO R E A RTH O B S E RVATI O N AT EX PO RT E S O E X TR E M E LY L A R G E TE L...

Open the catalog to page 3

LASER PROCESSES LASER GALVO SCANNING MIRRORS Mersen Boostec provides standard and custom active mirrors from 10 to 500 mm apertures, with a range of high reflective coatings. In particular, standard generic XY laser galvo-scanning mirrors from 10 to 100 mm aperture are provided in pairs. Glued mounts are also proposed for all standard shaft sizes. These products are distributed under the trademark optoSiC®. SiC REPLACES BERYLLIUM, WHOSE TOXICITY PROBLEMS ARE WELL KNOWN OPTOSIC® OPTICS • Low moment of inertia • Low dynamic flatness Peak-to-Valley (PV) • High resonance frequency • Fast...

Open the catalog to page 4

SEMICONDUCTOR AND OPTO-MECHANICS OEMs Mersen Boostec provides the silicon carbide ultra-stable structures that are now required by the semiconductor and optomechanical equipment. Application requests: high specific stiffness (Young’s modulus / Density) high thermal stability (Thermal Conductivity / Coefficient of Thermal Expansion) • High mechanical strength and absence of mechanical fatigue, • Perfect isotropy of the SiC material, • Flawless polishable finish which can be used as optical reference, • Perfect stability over time, • Water and gas tight, no outgassing, no moisture absorption,...

Open the catalog to page 5

CONTINUOUS FLOW REACTORS FOR THE CHEMICAL INDUSTRY SiC modules for continuous flow reactor is a technological breakthrough in the chemical industry Mersen Boostec develops and manufactures high-technology chemical reactors for continuous flow systems in cooperation with Corning SAS. KEY BENEFITS • Production steps reduced for higher productivity and increased safety • Improved chemical reactions • Smaller footprint than traditional reactors • Cost competitive solution TECHNICAL SPECIFICATIONS • FLOW RATE 2 TO 8000 ml/min • TEMPERATURE -60°C TO 200°C • PRESSURE UP TO 18 BAR • OPTIONS: ATEX...

Open the catalog to page 6

05 HEAT EXCHANGERS FOR THE CHEMICAL INDUSTRY No particle emission, no contamination for high purity applications SiC heat exchangers lead to optimized performance and are the first choice for applications in the pharmaceutical and fine chemicals industry. Most compact heat exchanger Solution suitable for extreme environment Easy maintenance It is a key solution for processes with high corrosion and for processes with high service rates (less maintenance). SiC heat exchangers are assembled as a stack of single element which is then inserted into a metallic shell. Seals are placed between the...

Open the catalog to page 7

PROPERTIES BOOSTEC® SILICON CARBIDE Theoritical density Bulk density Total porosity (fully closed) Coeffcient of Thermal Expansion Thermal conductivity Specific heat Maximum thermal shock (ATc) Maximum In air temperature of use in inert atmosphere Vickers hardness (500g load) Bending strength Mechanical strength Weibull modulus Tensile strength Compressive strength Kic toughness (SENB method) Young's modulus Shear modulus Poissons ratio TML (Total Mass Load) Typical value Boostec® SiC + manufacturing process CVD COATING ASSEMBLING Brazing, Gluing, | Bolting^^ DIMENSIONAL CONTROL DYE...

Open the catalog to page 8

MeR5eivl Expertise, our source of energy W GLOBAL EXPERT IN ELECTRICAL POWER AND ADVANCED MATERIALSAMERICAS MERSEN USA Bay City, PA Greenville, MI St Marys, PA MERSEN MEXICO Monterrey MERSEN ARGENTINA Buenos Aires MERSEN CHILE Santiago MERSEN COLUMBIA Bogota MERSEN BRAZIL Sao Paulo EUROPE & AFRICA MERSEN BENELUX Schiedam MERSEN GERMANY Suhl MERSEN FRANCE Centre of Expertise ZAE Ceram'Innov Pyrenees 65460 Bazet tel: +33 (0)5 62 33 45 00 MERSEN IBERIA Barcelona MERSEN TURKEY Gebze MERSEN ITALY Milan MERSEN NORDIC Kista MERSEN UK Teesside MERSEN SOUTH AFRICA Johannesburg ASIA & OCEANIA MERSEN...

Open the catalog to page 9All Mersen Power Transfer Technologies catalogs and technical brochures

-

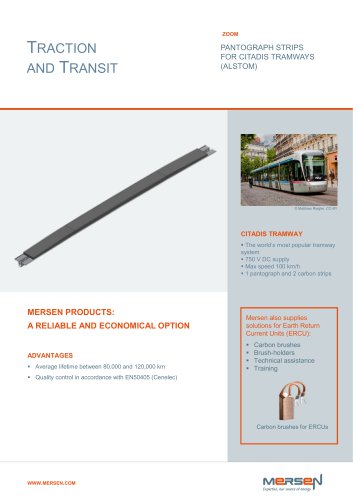

RAILWAYS & TRANSIT

2 Pages

-

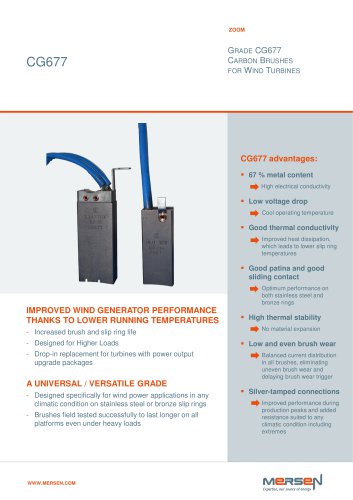

CG677

2 Pages

-

CURRENT COLLECTOR DEVICE

4 Pages

-

SURGE PROTECTION SOLUTIONS

24 Pages

-

TRANSPORTATION RAILWAYS

6 Pages

-

TRACTION AND TRANSIT

2 Pages

-

performance by mersen

20 Pages

-

PRODUCT CATALOG

348 Pages

-

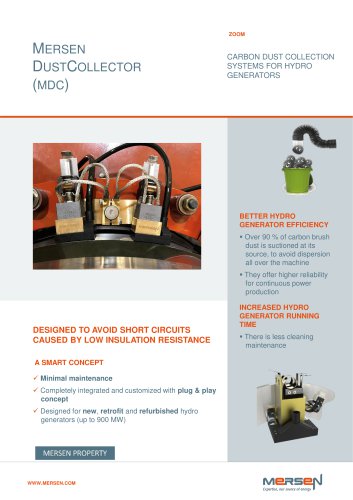

BRUSH GEAR SYSTEMS

5 Pages

-

MERSEN OEM WIND SOLUTIONS

2 Pages

-

BOOST HCl ACID CONCENTRATION

1 Pages

-

ULTIMATE HCl ABSORBER

1 Pages

-

EcoDesign 3rd rail shoes

2 Pages

-

Current Collection

32 Pages

-

Ski lifts

2 Pages