Catalog excerpts

SOLUTION TO PRODUCE HCl SOLUTION AT 35%, 36%, 37% or 38%. In this type of production, the main difficulty stems from the fact that the vapour pressure of the acid solution quickly becomes very high, meaning that the gradient between the partial pressure of the HCl gas and the vapour pressure of the solution falls and limits absorption. The quantity of gas not absorbed is therefore much higher than in the case of producing 33% acid. [Integrated cooler on Sintaclor] [Integrated cooler on Scrubber] SOLUTION #1 : CHANGE YOUR COOLING SOURCE SOLUTION #2 : SINTACLOR MODIFICATION Replace cooling water on service side by cooler water (chilled water for example) Add blocks in Absorber section cooled with chilled water. The design permits to the chiller part to be detached from the Absorber section. SOLUTION #3 : SCRUBBER MODIFICATION Evacuate the heat in the bottom part of the tail tower by internal cooling system. [Integrated cooler on Tank] SOLUTION #4 : HCl TANK MODIFICATION Cool the acid in the transfer tank by adding one heat exchanger in the re-circuclation loop. CUSTOMER BENEFIT GENERATE MORE PROFIT WITH YOUR PRODUCED HCl ACID SOLUTION BY MODIFICATION OF YOUR EXISTING SINTACLOR ®

Open the catalog to page 1All Mersen Power Transfer Technologies catalogs and technical brochures

-

RAILWAYS & TRANSIT

2 Pages

-

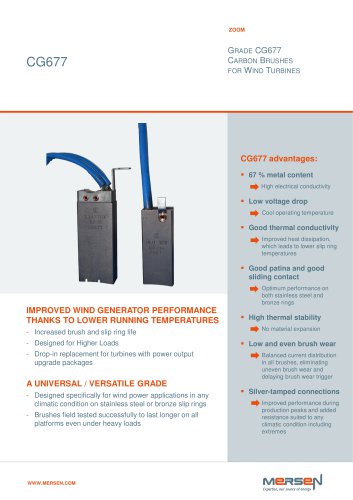

CG677

2 Pages

-

CURRENT COLLECTOR DEVICE

4 Pages

-

SURGE PROTECTION SOLUTIONS

24 Pages

-

TRANSPORTATION RAILWAYS

6 Pages

-

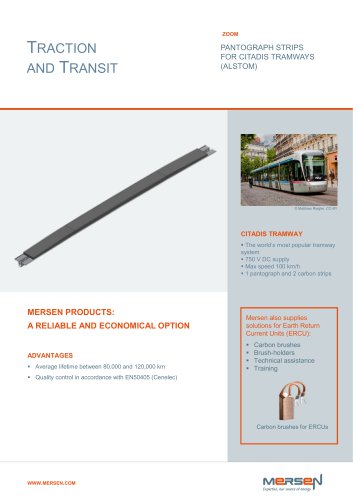

TRACTION AND TRANSIT

2 Pages

-

performance by mersen

20 Pages

-

BOOSTEC® SiC

9 Pages

-

PRODUCT CATALOG

348 Pages

-

BRUSH GEAR SYSTEMS

5 Pages

-

MERSEN OEM WIND SOLUTIONS

2 Pages

-

ULTIMATE HCl ABSORBER

1 Pages

-

EcoDesign 3rd rail shoes

2 Pages

-

Current Collection

32 Pages

-

Ski lifts

2 Pages