Catalog excerpts

Series M POLYBLOC heat exchangers are the mostextensively used GRAPHILOR block units.Built for the first time in 1953 following the patentingof a novel idea, they have been constantly improved and several thousands are in continuous operation in more than 50 countries.Their distinguishing features are their robustconstruction, exceptionally long working life and reliability in service.They are ideal for all applications in the chemicalindustry except in highly oxidising conditions.Their original design provides exceptional thermalefficiency, especially at low speeds or with viscous fluids.The POLYBLOC modular design especially the GMtype ח is very versatile. The user may increase or reduce the heat transfer area during the operation to meet his needs at very low cost..They are particularly suitable as multi-purpose units inthe fine chemical and pharmaceutical industries.Easy dismantling makes them well suited toapplications where fouling and deposits are likely to occur.Heat transfer surfaces range from 0.1m > 2 to 65m > 2 ata maximum operating pressure of 6to 8bars, according to the type. POLYBLOC HEAT EXCHANGERin GRAPHILOR SERIES M > Versatile design Modular design.Օ3 diameters of GRAPHILOR blocks.2 diameters of drilled holes.Օ4 grades of impregnation.Vertical or horizontal operation.ՕNumerous optional designs: falling film, 2 corrosivefluids, operation as a dephlegmator. >

Open the catalog to page 1

Reliability Rugged construction: the graphite is protected by asteel shell and is under constant compression.ՕSafe sealing system:gaskets of proven design insolid PTFE or PTFE lined, tie-rod and spring system maintaining a constant seal whatever the operating conditions, no danger of corrosive or toxic fluids leaking outside the shell.Exceptional corrosion resistance of the four gradesof GRAPHILOR (See corrosion chart, ref. GC5). Economic operation ՕSpace saving: due to the unique and originaldesign of the fluid passages, the M series units are particularly compact.The modular design is...

Open the catalog to page 2

The graphite blocks and headers are housed in asteel shell giving complete protection and mechanical strength to the assembly, which is maintained under compression by calibrated springs on each of the steel tie bolts to ensure sufficient pressure is constantly exerted on all the gaskets of the stacked GRAPHILOR blocks, whatever the operating conditions.The fluids are isolated by high performance sealingrings separating each graphite block from the next.To ensure the service fluid on the radial side of theunit follows a circuitous pattern, baffles are fixed to the outside of the graphite...

Open the catalog to page 3

PM 107 heatexchangers have only one set of radial holes.This is the smallest GRAPHILOR heat exchanger;the heat transfer area ranging from 0,2m > 2 to 2 m > 2 . There are two models:PM 8 in GRAPHILOR BS, HB or GH PM 107 in GRAPHILOR TH.In the PM 8 model, each block has twopassages;in the service side, the fluid flows from the periphery of the block to the central chamber and from the central chamber to the periphery.This layout cannot be used for the THimpregnation and the PM 8 HEAT EXCHANGER BLOCK PM 107 HEAT EXCHANGER BLOCK POLYBLOC HEAT EXCHANGER, TYPE PM > Assembly plate GRAPHILORheader...

Open the catalog to page 4

GM 8 and GM 16 .The heat transfer area ranges from 1m > GM 16 are alignedfrom one block to another, making them particularly suitable for use as condensers and evaporators. They are easy to clean without being dismantled and re-assembled.There are two models of this type of heat exchanger, > 2 to 10m > 2 . The 8 mm holes in the GM 8 are drilled in astaggered axial configuration to provide maximum efficiency. They are ideal for use in fine chemicals and pharmaceuticals applications.The 16 mm holes drilled in the > GRAPHILORfeaderAssembly plateRADIALCIRCUITSteel inletnozzleSteelshellBaffle...

Open the catalog to page 6

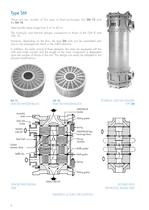

There are two models of this type of heat exchanger, the SM10 andthe SM18 .Heat transfer areas range from 5m > 2 to 60m > 2 .The hydraulic and thermal designs correspond to those of the GM 8 andGM16.However, depending on the flow, the type SM units can be assembled withone or two passages per block in the radial direction.In addition, the shells consist of three elements:the ends are equipped with theinlet and outlet nozzles and the length of the main component is dependent upon the number of blocks in the unit. This design can easily be adapted to suit process modifications. SM 10 SM 18...

Open the catalog to page 8

NUMBERLHWEIGHT (kg)HEATofFULLTRANSFERTBLOCKS(mm)(mm)EMPTYof WATER(m AREA AREA > 2 135 abt. 20 ) > NUMBERLHWEIGHT (kg)HEATofFULLTRANSFERTBLOCKS(mm)(mm)EMPTYof WATER(m 332 > 2 ) >

Open the catalog to page 9

NUMBERDIAMETER LENGTHHEATCROSSNUMBER ofTYPESofof HOLESof HOLESTRANSFER AREASECTIONAL AREAPOSSIBLEHOLES(mm)(mm)(m > 2 )(cm > 2 )PASSESPM 8 4881060.13241 PM 107 4271030.095161 GM 8 25681010.651301 GM 16 110161000.552201 SM 10 504102343.713951 SM 18 252182343.336401 > NUMBERDIAMETER LENGTHHEATCROSSNUMBER ofTYPESofof HOLESof HOLESTRANSFER AREASECTIONAL AREAPOSSIBLEHOLES(mm)(mm)(m > 2 )(cm > 2 )PASSESPM 8 648540.09322 PM 107 4871230.1318.51 GM 8 12881260.40641 GM 16 8081300.26401 SM 10 336102192.312651-2 SM 18 252102191.732001-2 >

Open the catalog to page 11All Mersen - Equipements Industriels et Anticorrosion catalogs and technical brochures

-

Boostec SiC

7 Pages

-

brush gear systems

5 Pages

-

systèmes anticorrosion intégrés

16 Pages

-

Systems

16 Pages

-

columns

12 Pages

-

heat exchanger

16 Pages

-

Bursting discs

16 Pages

-

Piping ANSI

36 Pages

-

ARMYLOR®

36 Pages

-

Piping and accessories

36 Pages

-

bursting discs - Technical guide

16 Pages

-

pressure vessel

12 Pages

Archived catalogs

-

Mixers

12 Pages

-

Polytube

6 Pages

-

Polybloc® NCNF

8 Pages

-

Cubic heat exchangers NK

8 Pages

-

Cubic heat exchangers NKG

8 Pages

-

Sintaclor®

8 Pages

-

Cubic heat exchangers KM

8 Pages

-

SKID Sintaclor®

8 Pages

-

Centrifugal Horizontal Pumps

6 Pages

-

FPE : Technical

40 Pages

-

Columns and Accessories

8 Pages

-

Centrifugal Vertical Pumps

4 Pages

-

Electrodes

6 Pages