Catalog excerpts

Merlo's factories in San Defendente di Cervasca (Cuneo) cover an area of 300,000 m2 (with 220,000 m2 indoor facilities) Merlo SpA main offices Final assembly lines Lines for assembling components and cabs Moulding of technopolymers Automated storing and shipping centre Machines plus attachments shipping centre Final quality control Technological centre Steel and structural assembly lines centre 3M attachments CFRM (Training & Research Centre)

Open the catalog to page 2

The Merlo Group N° 1 for technology and safety The Merlo brand has always been synonymous with advanced technology in the telehandler field and our history, since 1964, is hallmarked by experience based on determination and passion. The development of complex products, from the idea to the result, from design to sales, means being able to propose orientations for the most competitive markets. The outcome of our efforts are compact, easy to handle telehandlers ensuring incomparable operating performance, comfort, efficiency and safety. At Agritechnica 2013, three important awards were...

Open the catalog to page 3

Merlo, the inventor of the telehandler and its application in agriculture, presents the new Heavy Duty range

Open the catalog to page 4

New Merlo Heavy Duty range The telehandler in agriculture according to Merlo We were the first to launch a range of telehandlers dedicated to agriculture in 1996. Today, we proudly present the new generation developed on the strength of experience acquired in 50 years of operations. Cab compliant with ROPS and FOPS level II standards* M CDC Dynamic load control as standard Tilt correction as standard Largest cab in its category Suspended cab, a unique and patented solution -18% consumption with standard EPD Engines 170 HP** Rear differential lock as standard Mechanical PTO Rear hydraulic...

Open the catalog to page 5

New Merlo Heavy Duty Family Concentrated technology Innovative Merlo systems • Chassis tilt correction as standard • Tac-Lock rapid coupling of the attachments • Rear differential lock as standard Comfort • Largest cab on the market 1010 mm • “CS” cab with one of a kind h hydro-pneumatic matic suspensions Hydraulic system options ulic • Load sensing + Flow Sharing pump ndard as standard onic • Electronic joystick Efficiency – Powertrain • Tier 4 Final Engines - 170 HP • Models with 2-speed hydrostatic n transmission and with CVTronic n transmission as standard ower • EPD – Eco Power Drive –...

Open the catalog to page 6

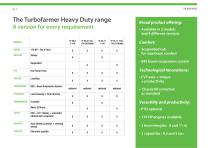

The Turbofarmer Heavy Duty range A version for every requirement Broad product offering: • Available in 2 models and 4 different versions Comfort: • Suspended cab for maximum comfort • BSS boom suspension system Technological Innovations: • CVTronic + torque + productivity • Chassis tilt correction as standard Versatility and productivity: • PTO optional • 170 HP engines available • 2 boom lengths - 8 and 11 m • 2 capacities - 4,5 and 5 ton

Open the catalog to page 7

ENGINES & TRANSMISSIONS Engines & Transmissions Higher performance and lower consumption Turbofarmer “Heavy duty” range is equipped with two Tier 4 Final engines: 125 kW/170HP The hydrostatic transmission with EPD (Eco Power Drive) as standard . Merlo always Merlo telehandlers are equipped with hydrostatic transmissions for improved precision, safety As and ease of use. The EPD can reduce fuel consumption by 18% giving a real yearly saving. 2 button that allows to save the movement speed of the machine and keep it constant. The Eco function, ideal for yard handling operations,...

Open the catalog to page 8

MERLO CVTRONIC Merlo CVTronic Merlo's own continuous variable transmission version The CVTronic transmission follows Merlo's traditions in the hydrostatic field and ensures smooth acceleration without interrupting torque from 0 to 40 km/h. The transmission comprises two axial piston hydrostatic engines powered by the electronicallycontrolled hydraulic pump. At low work speeds, they function in conjunction to provide maximum torque, with an increase of + 12% with respect to conventional hydrostatic transmissions. During transport, the second hydrostatic engine is automatically disengaged...

Open the catalog to page 9

Largest cab in the category 1. Merlo CDC: the patented Merlo safety system that provides new standards of safety. 2. New Joystick with reverse shuttle (duplicated on steering wheel): ergonomic and easy to use. 3. New display makes it possible to display a great deal of useful information for the operator. 4. New air conditioning system in line with automotive standards for fast and effective heating/cooling. 5. Inching-Control: the dedicated pedal provides calibrated movements of the machine. 6. Curved windscreen: maximum visibility and safety in work at height. 7. Differential lock. 8....

Open the catalog to page 10

Comfort record World exclusive cab with suspensions AIR-CONDITIONING SYSTEM The new cab was developed to ensure record-breaking comfort for our users. At 1010 mm, it is the largest in its category, yet even acoustic and thermal comfort involved detailed design; the cab is also pressurised to prevent dust entering the cockpit. The air conditioning system is completely new and was developed based on automotive standards, halving the warm-up and cooldown times, guaranteeing an optimal temperature in all conditions. The new Merlo cab can now reach an internal temperature of 22°C with an...

Open the catalog to page 11

CDC as standard on the entire range safety before everything else! r* MERLO DYNAMIC LOAD CONTROL The MCDC system verifies the conditions of longitudinal stability in real time and provides the operator with an indication of the percentage of usage of the maximum stability condition. 1. Icon with attachment in use 3. Load positioning (in work area) 4. Load detection menu

Open the catalog to page 12

Merlo Dynamic Load Control Safety as standard for everyone The Merlo Group considers safety as an absolutely essential value and this is why it invented the M CDC system. The objective is to allow every operator to work in total safety by fully exploiting the potential of the telehandler and the attachment used. The Merlo CDC system means that the Turbofarmer automatically recognises the attachment fitted and consequently calibrates its performance in relation to specific load charts. The operator can check at any time the dynamic equilibrium of the vehicle, thanks to the led on the screen...

Open the catalog to page 13All MERLO SPA catalogs and technical brochures

-

Dumper

4 Pages

-

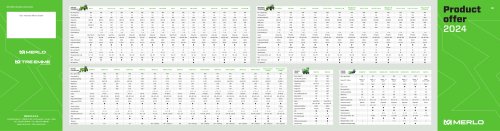

Product offer 2024

2 Pages

-

e-WORKER 25.5

5 Pages

-

HEAVY DUTY Telehandlers

28 Pages

-

MEDIUM CAPACITY Telehandlers

24 Pages

-

COMPACT Telescopic Handlers

20 Pages

-

eWORKER

20 Pages

-

CONCRETE MIXER

2 Pages

-

Telehandlers ROTARY

24 Pages

-

PANORAMIC HIGH CAPACITY

28 Pages

-

TOOL CARRIERS X SERIES

8 Pages

-

COMPACT P27.6

12 Pages

-

MERLO S.P.A

2 Pages

-

TRACKED CARRIERS

20 Pages

-

Roto

36 Pages

-

HIGH CAPACITY

12 Pages

-

COMPACTS

12 Pages

-

2016 COMPACT FAMILY

20 Pages

-

MERLO TELEHANDLER

20 Pages

-

Cingo

16 Pages

-

Professionals Brochure

4 Pages

-

TURBOFARMER P 50.8

12 Pages

-

TURBOFARMER II

28 Pages

-

NEW TF 38.7-120 G

28 Pages

-

Panoramic P72.10 / P60.10

4 Pages

-

TreEmme Brochure

12 Pages

-

dbm

16 Pages

-

Multifarmer brochure

16 Pages

-

Turbofarmer Brochure

28 Pages

-

PANORAMIC SERIE CS

4 Pages

-

Multifarmer 27.8

4 Pages

-

Turbofarmer P 34.10 Plus

28 Pages

-

Panoramic P 34.10

12 Pages

-

Compact P 25.6

16 Pages

Archived catalogs

-

2015 COMPACT FAMILY

24 Pages

-

DBM

8 Pages

-

Turbofarmer / P 34.7 PLUS

16 Pages

-

Panoramic /P 34.7

12 Pages

-

COMPACTS / P 28.8 L

4 Pages