Website:

MEP

Website:

MEP

Group: MEP GROUP

Catalog excerpts

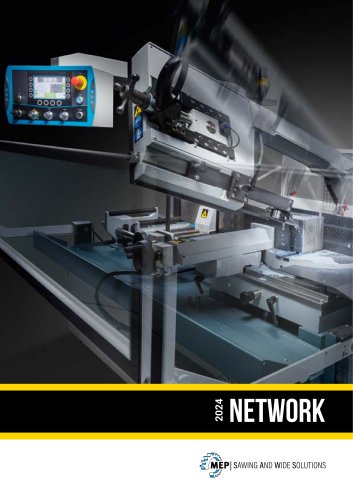

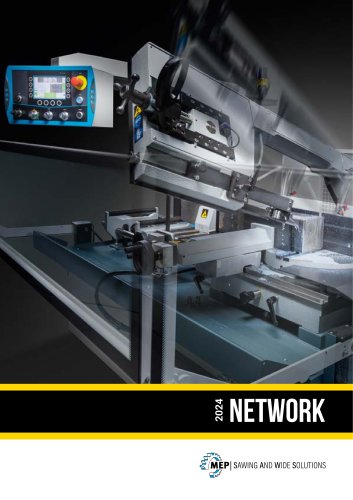

network INDUSTRY

Open the catalog to page 1

MEp group The MEP Group today represents the latest stage in the evolution of the know-how, technology and values that MEP has developed over a period of 50 years. The MEP Group is present on all major markets and is a leader in those of most importance. The group has production plants in Italy, Canada, the USA and China which produce around 12,000 machines a year. MEP products are sold in over 50 nations around the world thanks to close collaboration with highly qualified local distributors and/or directly controlled subsidiaries (China and Brazil). The MEP Group’s extensive product range...

Open the catalog to page 2

mep around the world MEP (SUZHOU) CO. LTD (PR. CHINA) MEP (SUZHOU) CO. LTD Suzhou P.R. China

Open the catalog to page 3

WORKSHOP Enzo Magnani 1959 The TV 300 was MEP’s first series-made abrasive disc cutting machine.

Open the catalog to page 4

MADE WITH COMMITMENT AND PASSION The MEP Group has firm roots in one of the many entrepreneurial families that thrive in a region rich in hard-working people, history and art. It all began in a small workshop in the historical centre of Pergola, a town in the province of Pesaro-Urbino, in the Marche region of Italy. Enzo Magnani began his career as a mechanic, exploiting the skills he had acquired with British and American forces based in Italy during the Second World War. The ingenuity he showed in his small workshop led to the creation of the first sawing machine, which proved so...

Open the catalog to page 5

cutting mode AUTOMATIC cutting mode SEMI-AUTOMATIC cutting mode SEMI-AUTOMATIC DYNAMIC CCS cutting mode Cut Control System cutting mode MANUAL ELECTROHYDRAULIC ELECTROPNEUMATIC ELECTROMECHANIC

Open the catalog to page 6

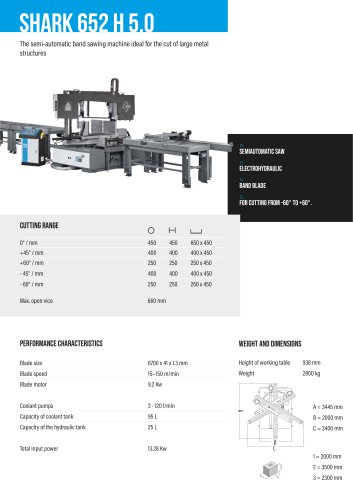

index loading magazine bandsawing machines vertical sawing machines for metals OPTIONALS technical features SHARK 350 NC HS 5.0 SHARK 350 CNC HS 4.0 SHARK 420 CNC HS 4.0 SHARK 660 CNC HS 4.0 SHARK 512 CCS hydra SHARK 512 SXI evo SHARK 652 SXI H 5.0

Open the catalog to page 7

STANDARD OPTIONAL SHARK 350 NC HS 5.0, electrohydraulic automatic double-column bandsaw for 0° cuts on profiles and solid parts in structural, stainless and alloy steels, for dimension up and in between 350mm x 350mm Standard machine features: + Motorized chip conveyor which can be assembled on the left or right handside of the machine + Variable vice pressure allow to set the clamping force + Two vertical rollers assembled on the feeding vice to help align the material - Numeric controlled machine CNC MEP 50-Windows “CE” based, that has been specifically designed by MEP for the automation...

Open the catalog to page 8

- Rest piece that can no longer be fed in by the feeding vice : 120 mm. ( Optional feeding vice jaws in order to reduce the restpiece down to 25mm+cutting length). - Blade deviation ( Optional) - Self-aligning feeder vice unit for feeding even not straight bars - Driving pulley locked by conical clamping ring to ensure a strong fastening still allowing axial adjustment - Software to control/assess/correct in real time: - cutting force – cutting torque and band tensioning against the programmed values - Adjustable steel blade-guide heads, with roller and carbide pads, coolant taps for the...

Open the catalog to page 9

STANDARD OPTIONAL Shark 350 CNC HS 4.0, automatic double-column bandsaw for 0° cuts on structural, stainless and alloys teels, profiles and solidparts, with dimensions up to 350x350 mm. Standard machine features: + Motorized chip conveyor which can be assembled on the left or right handside of the machine + Variable vice pressure allow to set the clamping force + Two vertical rollers assembled on the feeding vice to help align the material - CNC machine with MEP 40 controller that has been specifically designed by MEP for the automation of its range of products. - This sawing machine also...

Open the catalog to page 10

later on the control memory, through the suitable slot on the control console. - Choose in the library (that can be extended by the user) the material type, geometry and hardness, the type of blade to be used and the control automatically sets the feed rate and the band rotation speed. - When equipped with sensors (OPTIONAL) that read the beginning and end of the bar , the CNC control activates 3 cycles : 1- Progressive feeding cycle : Cuts progressively all the length of pieces that are obtained in one stroke ( 600mm) which brings down cutting times. 2- Feeding rest piece cycle The rest...

Open the catalog to page 11

Shark 420 CNC HS 4.0, automatic double-column bandsaw for 0° cuts on structural, stainless and alloy steels, profiles and solid parts, with dimensions up to 420x420 mm. - CNC machine with a new controller: MEP 40. It has been specifically designed by MEP for the automation of its range of products - This sawing machine also features a semiautomatic cutting cycle and uses latest generation technologies; indeed, Shark 420 CNC HS 4.0 is equipped with a NEW controller with processor RISC 32 bit 200 MHz with integrated interface to: - Install a GSM card (OPTIONAL) to send an SMS to the...

Open the catalog to page 12

- Minimum bar remnant of 120 mm in automatic operation. (OPTIONAL feeder jaws to reduce the remnant to min. 25mm) - Driving and idler pulley locked by conical clamping ring to ensure a strong fastening. - Software to control/assess/correct in real time: - cutting force – cutting torque and band tensioning against the programmed values. - Low voltage control panel installed on a rotating arm to reach the positions to operate safely stillkeeping the visual control. - 8” touch screen display operator interface and push buttons for all functions of the sawing machine. It is simple and...

Open the catalog to page 13

Shark 660 CNC HS 4.0, automatic double-column bandsaw for 0° cuts on structural, stainless, alloy steels, profiles ,solid parts and profiles with dimensions up to 660x660mm. - CNC machine with a new controller: MEP 40. It has been specifically designed by MEP for the automation of its range of products. - This sawing machine also features a semiautomatic cutting cycle and uses latest generation technologies; indeed, Shark 660 CNC HS 4.0 is equipped with a NEW controller with processor RISC 32 bit 200 MHz with integrated interface to: - Install a GSM card (OPTIONAL) to send an SMS to the...

Open the catalog to page 14All MEP catalogs and technical brochures

-

VELOCEX 175

1 Pages

-

VELOCEX 150

1 Pages

-

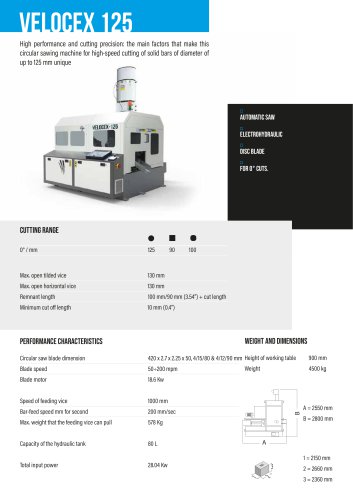

VELOCEX 125

1 Pages

-

VELOCEX 100

1 Pages

-

VELOCEX 80

1 Pages

-

VELOCEX 65

1 Pages

-

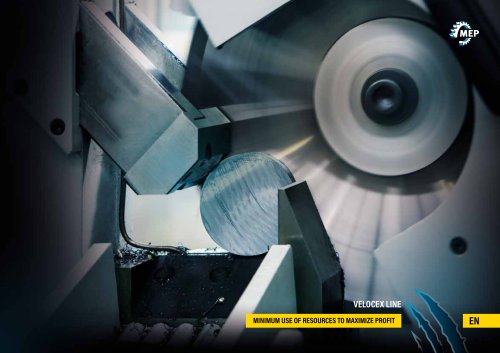

VELOCEX LINE

20 Pages

-

TIGER 402 CNC HR 4.0 RC

1 Pages

-

TIGER 402 CNC HR 4.0

1 Pages

-

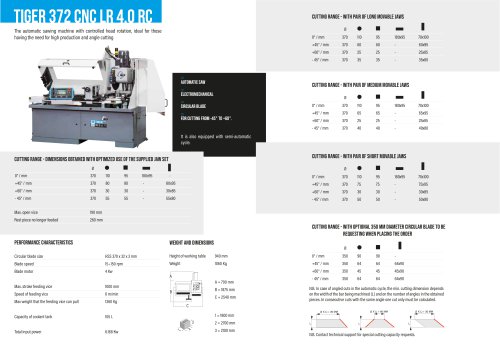

TIGER 372 CNC LR 4.0 RC

1 Pages

-

TIGER 372 CNC LR 4.0

1 Pages

-

TIGER 352 NC 5.0

1 Pages

-

2024 NETWORK - TIGER 352 NC 5.0

22 Pages

-

TIGER 372 SX EVO

1 Pages

-

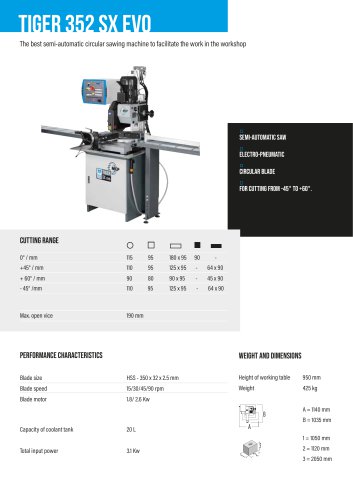

TIGER 352 SX EVO

1 Pages

-

2024 NETWORK - TIGER 352 SX EVO

20 Pages

-

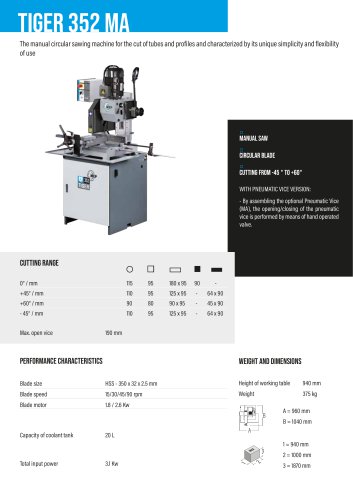

TIGER 352 MA

1 Pages

-

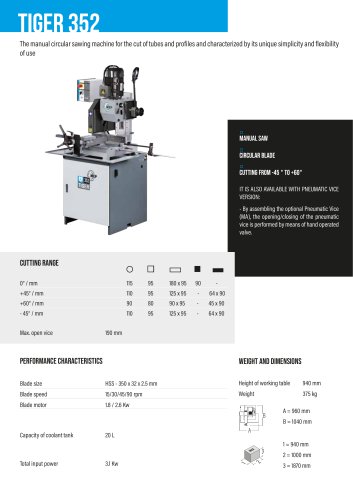

TIGER 352

1 Pages

-

COBRA 352 NC 5.0

1 Pages

-

2024 NETWORK - COBRA 352 NC 5.0

22 Pages

-

COBRA 352 SX EVO

1 Pages

-

2024 NETWORK - COBRA 352 SX EVO

20 Pages

-

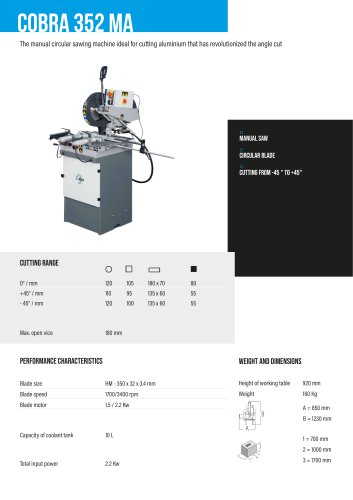

COBRA 352 MA

1 Pages

-

2024 NETWORK - COBRA 352 MA

20 Pages

-

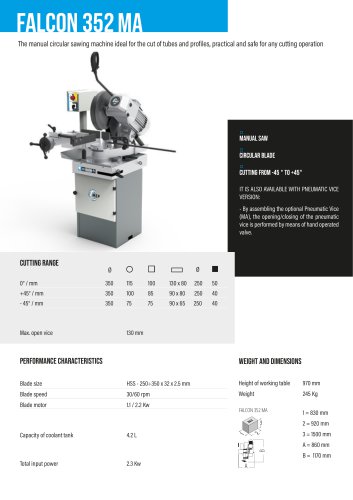

FALCON 352 MA

1 Pages

-

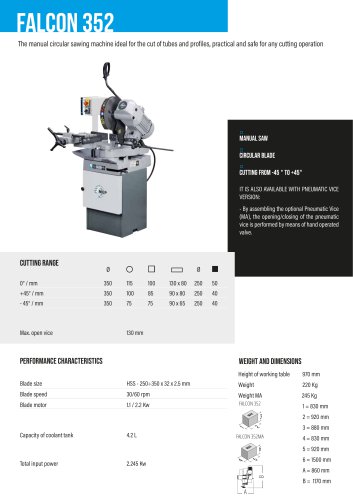

FALCON 352

1 Pages

-

SHARK 660 CNC HS 4.0

1 Pages

-

SHARK 460 KONNECT

1 Pages

-

SHARK 350 CNC HS 4.0

1 Pages

-

SHARK 350 NC HS 5.0

1 Pages

-

SHARK 230-1 NC HS 5.0

1 Pages

-

SHARK 332 RC KONNECT

1 Pages

-

SHARK 332-1 NC 5.0

1 Pages

-

SHARK 331-1 NC 5.0 SPIDER

1 Pages

-

SHARK 281 NC 5.0

1 Pages

-

2024 NETWORK - SHARK 281 NC 5.0

24 Pages

-

THOR 860

1 Pages

-

THOR 660

1 Pages

-

THOR 560

1 Pages

-

THOR 450

1 Pages

-

2023 THOR Line

28 Pages

-

SHARK 652 SXI H 5.0 AUTO

1 Pages

-

SHARK 652 SXI H 5.0

1 Pages

-

SHARK 512 SXI EVO

1 Pages

-

SHARK 452-1 SXI EVO

1 Pages

-

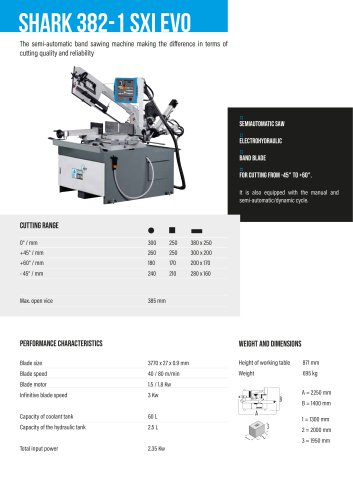

SHARK 382-1 SXI EVO

1 Pages

-

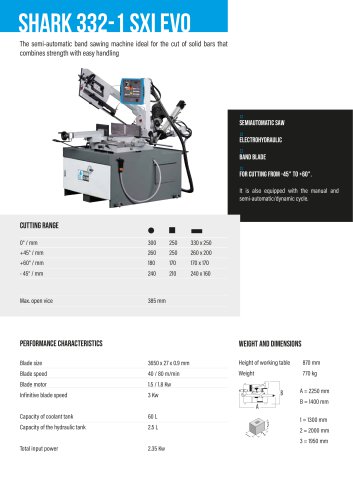

SHARK 332-1 SXI EVO

1 Pages

-

SHARK 282 SXI EVO

1 Pages

-

2024 NETWORK - SHARK 282 SXI EVO

22 Pages

-

SHARK 281 SXI EVO

1 Pages

-

2024 NETWORK - SHARK 281 SXI EVO

22 Pages

-

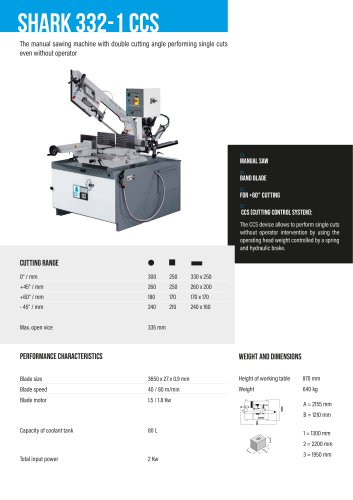

SHARK 332-1 CCS

1 Pages

-

2024 NETWORK - SHARK 332-1 CCS

22 Pages

-

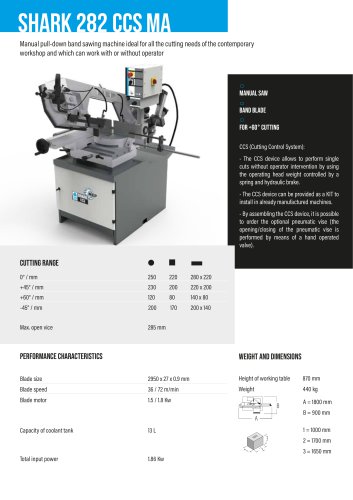

SHARK 282 CCS MA

1 Pages

-

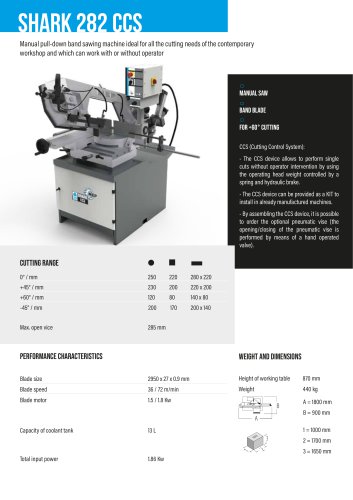

SHARK 282 CCS

1 Pages

-

SHARK 282

1 Pages

-

2024 NETWORK - SHARK 282

22 Pages

-

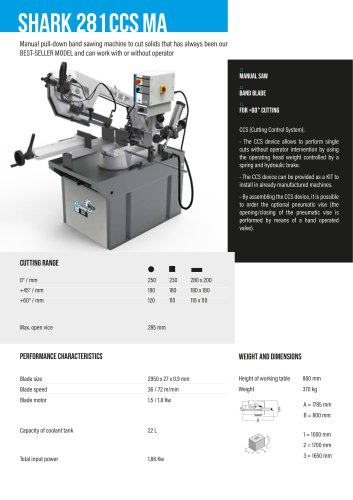

SHARK 281 CCS MA

1 Pages

-

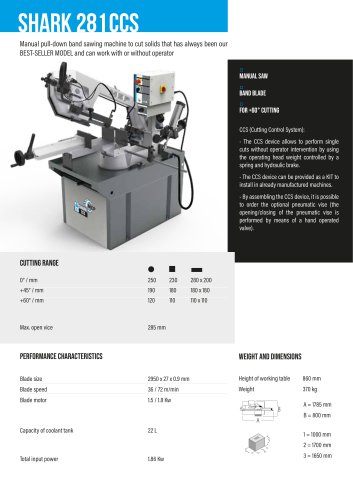

SHARK 281 CCS

1 Pages

-

SHARK 281

1 Pages

-

2024 NETWORK - SHARK 281

24 Pages

-

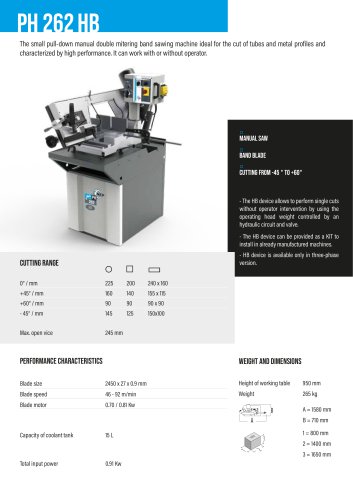

PH 262 HB

1 Pages

-

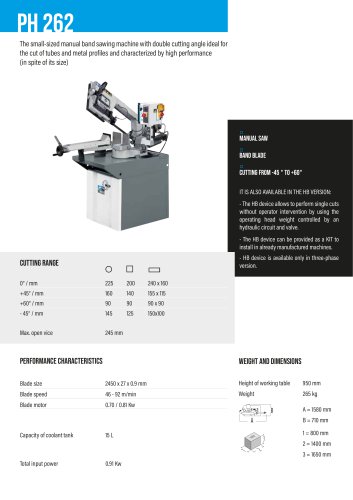

PH 262

1 Pages

-

PH 261-1 HB

1 Pages

-

PH 261-1

1 Pages

-

PH 211-1 HB

1 Pages

-

PH 211-1

1 Pages

Archived catalogs

-

THOR LINE

20 Pages

-

SMV 3000

1 Pages

-

SMV 3000 PRO

1 Pages

-

CB 6001

2 Pages

-

Industry

36 Pages

-

Network - GENERAL CATALOGUE 2014

80 Pages

-

Catalogue MEP

88 Pages