Website:

MEP

Website:

MEP

Group: MEP GROUP

Catalog excerpts

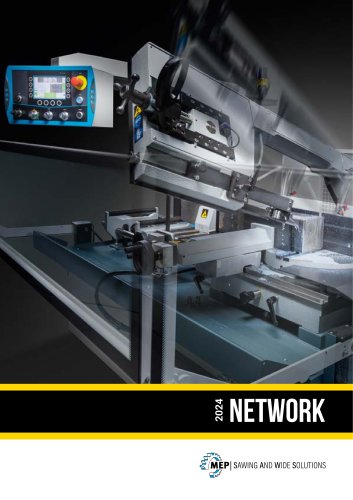

NETWORK | SAWING AND WIDE SOLUTIONS

Open the catalog to page 1

REVOLUTIONIZING THE FUTURE OF METAL CUTTING THROUGH INNOVATIVE SUSTAINABLE TECHNOLOGIES “... Our products and services for metal cutting are transforming the future of digital factory by offering a wide range of solutions to improve the efficiency and automation of production processes: this holistic approach has actually consolidated Industry 4.0 standards and is helping to define the new horizons of Industry 5.0 through programming and management, control and monitoring software applications, exclusive cutting cycles and integration services.” mep group We are specialized in the design...

Open the catalog to page 2

Countries to which our products are distributed Sawing machines models Material Handling System solutions Customized solutions manufactured annually Machines manufactured annually Euro annual turnover 1000 x 2000 Maximum cutting capacity (mm) "... Believing that digitalization is the key to remaining competitive in the market and improving the quality of products and services, our goal is to promote innovation and sustainable development by putting at the service of our customers solutions that integrate the knowledge gained during the digitalization process: actually, as part of our...

Open the catalog to page 3

PRODUCTION PROCESS The excellent cutting precision of MEP machines is largely due to their G25 cast iron frames, which are deburred and then blasted with steel shot prior to painting. To ensure maximum flexibility in production, a large number of these painted, cast iron frames are always kept in stock ready for machining. Nearly all material is processed in MEP’s three FMS machining centres. These are served from a single automated warehouse system capable of handling a large number of different parts uninterruptedly, even overnight, to ensure maximum flexibility in production. Each...

Open the catalog to page 4

QUALITY CONTROL MACHINED CAST IRON STORES ASSEMBLY ISLANDS A measuring system that operates at a controlled temperature samples the dimensions of machined parts to ensure constant uniformity. Once machined, cast iron parts are stored in a large warehouse ready for picking and assembly. A dedicated department assembles all complex mechanisms and performs all adjustments and calibrations that require particular care. 10 assembly islands, each handling limited quantities at a time, are served by the high speed FMS machining centres and large castings store to ensure extremely flexible...

Open the catalog to page 5

legend AUTOMATIC CUTTING CYCLE THREE-PHASE POWER SEMI-AUTOMATIC CUTTING CYCLE SEMI-AUTOMATIC/DYNAMIC CUTTING CYCLE CUTTING SPEED SELECTOR INVERTER MOTOR POWER MANUAL CUTTING CYCLE CUTTING ANGLE FERROUS MATERIALS NON-FERROUS MATERIALS CIRCULAR BLADE/BAND SIZE SAWING MACHINE WEIGHT The manufacturer reserves the right to carry out modifications without notice. The published photos may include non-standard details.

Open the catalog to page 6

COBRA THE IDEAL SOLUTION FOR LIGHT ALLOYS MEP is specialized in the cutting of all types of ferrous material and, with the COBRA line, it completes its offer by providing solutions for those who need to cut light alloys. Aluminium, bronze, copper, etc. can therefore be cut ensuring excellent finishing and production. Moreover, our engineering team can develop customized solutions for materials or extruded with irregular geometries. Thanks to the COBRA range, MEP further strengthens its position as a SINGLE SUPPLIER FOR ANY CUTTING NEED! MANUAL Ideal sawing machines for small size production...

Open the catalog to page 7

352 nc 5.0 MITER CUTTING • LIGHT ALLOYS • TUBES • PROFILES • EXTRUDED F COBRA 352 NC 5.0, electropneumatic automatic sawing machine with electrowelded hard-metal blade to cut light alloys, aluminium profiles and solids mitering from -45° to +45°. MAXIMUM PRODUCTION MAXIMUM PRECISION • The cast-iron structure absorbs vibrations and ensures greater cutting stability and longer blade life. • The bar feeder powered by stepper motor is a guarantee of high precision. • The control allowing to store up to 100 cutting programs, each one with different quantities and lengths, minimizes programming...

Open the catalog to page 8

KIT IOT ADAPTATIVE SAW HEAD DOWN FEED RATE Self-regulation in real-time of head down feed rate according to type of material or blade wear. TILTING HEAD The optional IOT allows to maximize data collection and use them in favor of a better sawing machine cutting performance and longer blade life. The sawing machine cuts light alloys, aluminium profiles and solids from -45° to +45°. The saw head is vertically adjustable to also perfom cuts with head tilting from 0° to +45°. TURNING CUTTING TABLE The turning cutting table is assembled on a central pin and thrust bearing thus allowing an easy...

Open the catalog to page 9

OPTIONS cobra OPTION N° 02 Spray mist system KIT MES options cobra Pneumatic vertical vice Foot pedal control for vice (only MA) Adapter for unloading table Supplementary foot pedal control with emergency stop Pneumatic vertical vice (only MA v

Open the catalog to page 12

Set of comb jaws for bundle cutting max 70x70 mm Chip collector electrical connection Special vice to reduce remnant (max 220 mm) Chip collector Turbo 2500 Set of nylon comb jaws max 75x75 mm Set of nylon comb jaws (max 75x75 mm) for special vice to reduce remnant (to order only if combined with the vice to reduce remnant) OPTION N° 56 Roller conveyor KK200V/1500 mm Rollers inclined at 45° when machine equipped with bundle comb jaws options cobra

Open the catalog to page 13

CONVEYORS FOR SAWING MACHINES KK MOTORIZED ROLLER CONVEYORS CONVEYORS FOR SAWING MACHINES

Open the catalog to page 14

• ADDITIONAL SUPPORT TRAY COOLANT RECOVERY HYDRAULIC SQUARING VICE ADJUSTABLE VERTICAL ROLLER HEAVY-DUTY VERTICAL ROLLER TWO SETS OF VERTICAL ROLLERS VERTICAL ROLLER OPTIONS IDLER CONVEYORS TRUCK & TROLLEY CROSS TRANSFER CHAIN CROSS TRANSFER MEASURING STOP DEVICE FLASH MEASURING STOP DEVICE R4 STAGING SKIDS SAFETY FILLER PLATES MEASURING STOP DEVICE R3

Open the catalog to page 15

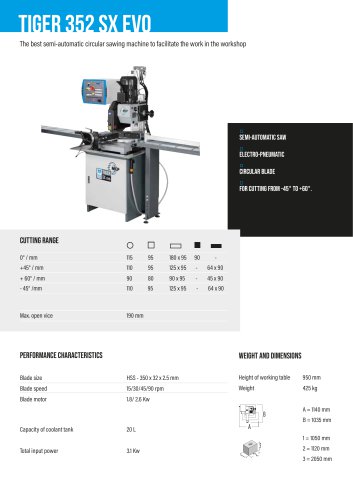

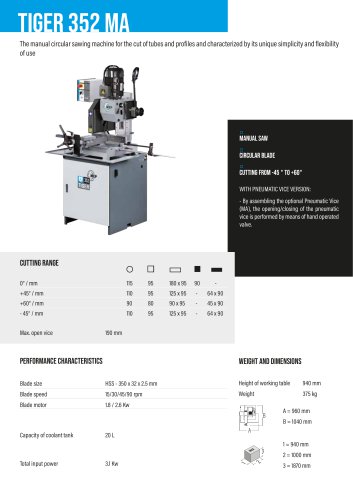

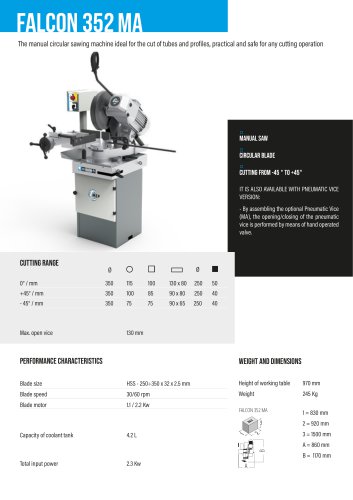

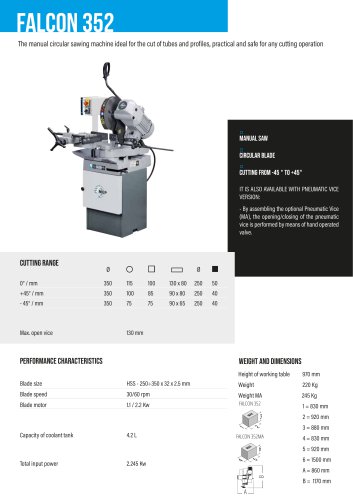

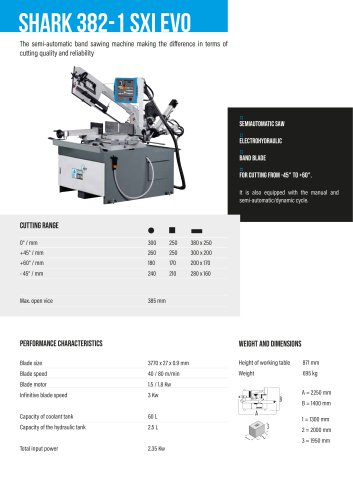

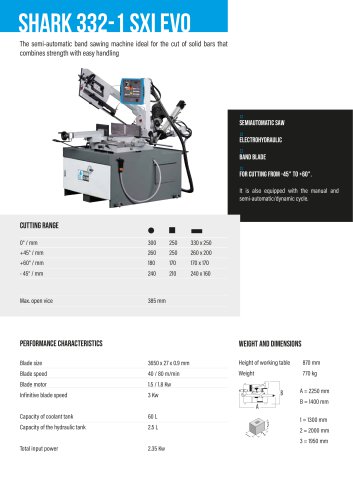

Rest piece no longer feeded standard (mm) Minimum cutting length (mm) Cutting capacity with overhead bundling (mm) Speed of feeding vice (m/min) Max. weight that the feeding vice can pull (kg) Working table height (mm) TECHNICAL SPECIFICATIONS SHARK 281 SHARK 281 CCS/MA SHARK 281 SXI evo 260 SHARK 281 NC 5.0 SHARK 282 SHARK 282 CCS/MA SHARK 282 SXI evo SHARK 331-1 NC 5.0 SPIDER 210 SHARK 332-1 CCS SHARK 332-1 SXI evo SHARK 332-1 NC 5.0 400 SHARK 382-1 SXI evo SHARK 452-1 SXI evo SHARK 230-1 NC HS 5.0 85 TIGER 352/MA TIGER 352 SX evo TIGER 352 NC 5.0 TIGER 372 SX evo FALCON 352 FALCON 352 MA...

Open the catalog to page 16All MEP catalogs and technical brochures

-

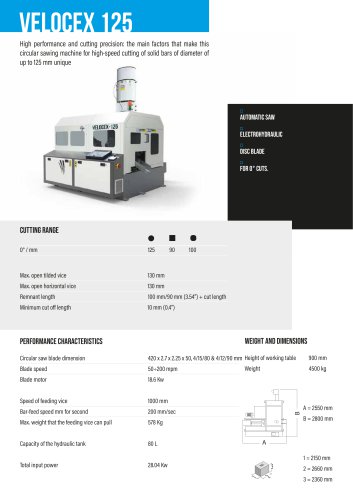

VELOCEX 175

1 Pages

-

VELOCEX 150

1 Pages

-

VELOCEX 125

1 Pages

-

VELOCEX 100

1 Pages

-

VELOCEX 80

1 Pages

-

VELOCEX 65

1 Pages

-

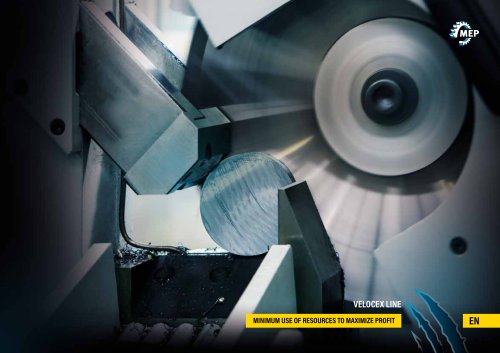

VELOCEX LINE

20 Pages

-

TIGER 402 CNC HR 4.0 RC

1 Pages

-

TIGER 402 CNC HR 4.0

1 Pages

-

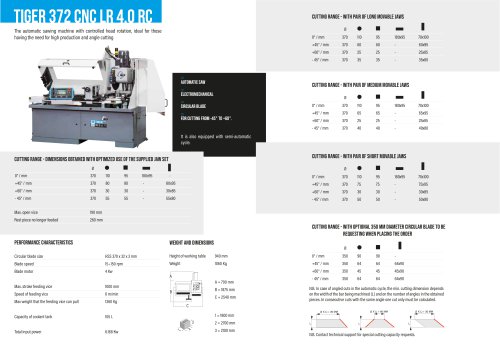

TIGER 372 CNC LR 4.0 RC

1 Pages

-

TIGER 372 CNC LR 4.0

1 Pages

-

TIGER 352 NC 5.0

1 Pages

-

2024 NETWORK - TIGER 352 NC 5.0

22 Pages

-

TIGER 372 SX EVO

1 Pages

-

TIGER 352 SX EVO

1 Pages

-

2024 NETWORK - TIGER 352 SX EVO

20 Pages

-

TIGER 352 MA

1 Pages

-

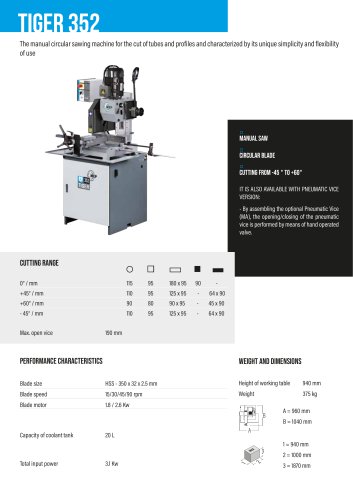

TIGER 352

1 Pages

-

COBRA 352 NC 5.0

1 Pages

-

COBRA 352 SX EVO

1 Pages

-

2024 NETWORK - COBRA 352 SX EVO

20 Pages

-

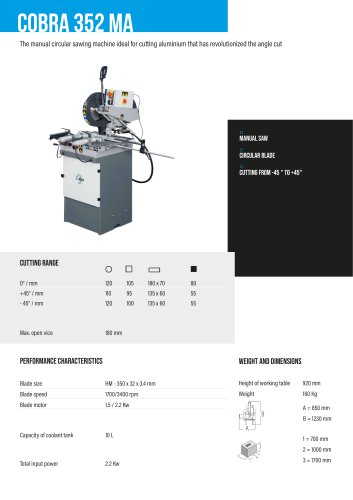

COBRA 352 MA

1 Pages

-

2024 NETWORK - COBRA 352 MA

20 Pages

-

FALCON 352 MA

1 Pages

-

FALCON 352

1 Pages

-

SHARK 660 CNC HS 4.0

1 Pages

-

SHARK 460 KONNECT

1 Pages

-

SHARK 350 CNC HS 4.0

1 Pages

-

SHARK 350 NC HS 5.0

1 Pages

-

SHARK 230-1 NC HS 5.0

1 Pages

-

SHARK 332 RC KONNECT

1 Pages

-

SHARK 332-1 NC 5.0

1 Pages

-

SHARK 331-1 NC 5.0 SPIDER

1 Pages

-

SHARK 281 NC 5.0

1 Pages

-

2024 NETWORK - SHARK 281 NC 5.0

24 Pages

-

THOR 860

1 Pages

-

THOR 660

1 Pages

-

THOR 560

1 Pages

-

THOR 450

1 Pages

-

2023 THOR Line

28 Pages

-

SHARK 652 SXI H 5.0 AUTO

1 Pages

-

SHARK 652 SXI H 5.0

1 Pages

-

SHARK 512 SXI EVO

1 Pages

-

SHARK 452-1 SXI EVO

1 Pages

-

SHARK 382-1 SXI EVO

1 Pages

-

SHARK 332-1 SXI EVO

1 Pages

-

SHARK 282 SXI EVO

1 Pages

-

2024 NETWORK - SHARK 282 SXI EVO

22 Pages

-

SHARK 281 SXI EVO

1 Pages

-

2024 NETWORK - SHARK 281 SXI EVO

22 Pages

-

SHARK 332-1 CCS

1 Pages

-

2024 NETWORK - SHARK 332-1 CCS

22 Pages

-

SHARK 282 CCS MA

1 Pages

-

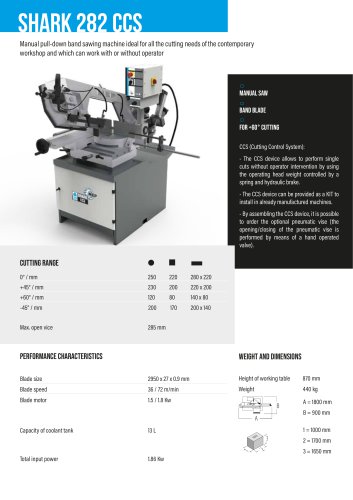

SHARK 282 CCS

1 Pages

-

SHARK 282

1 Pages

-

2024 NETWORK - SHARK 282

22 Pages

-

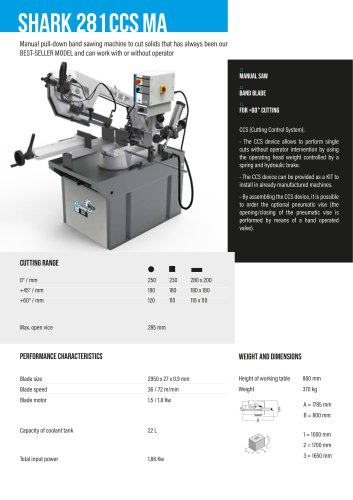

SHARK 281 CCS MA

1 Pages

-

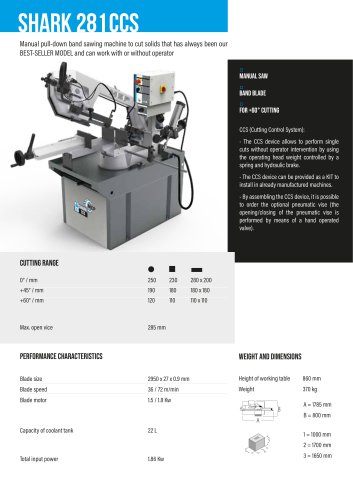

SHARK 281 CCS

1 Pages

-

SHARK 281

1 Pages

-

2024 NETWORK - SHARK 281

24 Pages

-

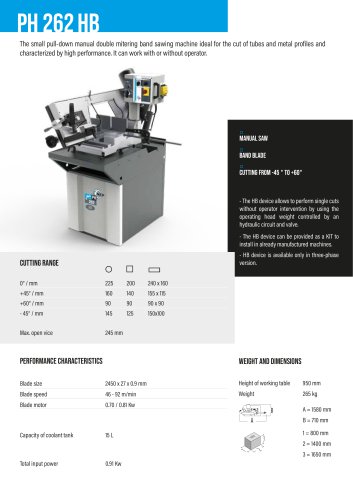

PH 262 HB

1 Pages

-

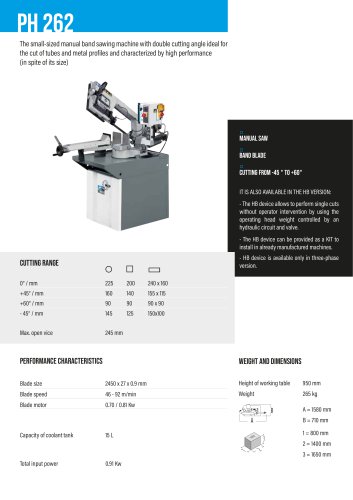

PH 262

1 Pages

-

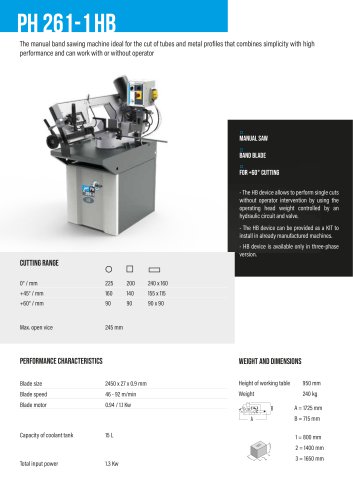

PH 261-1 HB

1 Pages

-

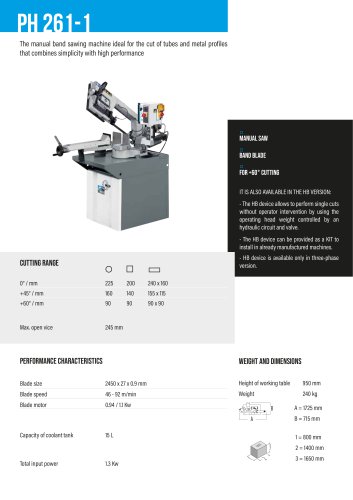

PH 261-1

1 Pages

-

PH 211-1 HB

1 Pages

-

PH 211-1

1 Pages

Archived catalogs

-

THOR LINE

20 Pages

-

SMV 3000

1 Pages

-

SMV 3000 PRO

1 Pages

-

CB 6001

2 Pages

-

Industry

36 Pages

-

Network - GENERAL CATALOGUE 2014

80 Pages

-

Catalogue MEP

88 Pages