Website:

MEP

Website:

MEP

Group: MEP GROUP

Catalog excerpts

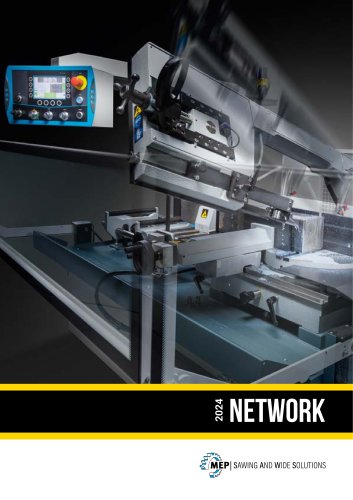

INDUSTRY | SAWING AND WIDE SOLUTIONS

Open the catalog to page 1

REVOLUTIONIZING THE FUTURE OF METAL CUTTING THROUGH INNOVATIVE SUSTAINABLE TECHNOLOGIES “... Our products and services for metal cutting are transforming the future of digital factory by offering a wide range of solutions to improve the efficiency and automation of production processes: this holistic approach has actually consolidated Industry 4.0 standards and is helping to define the new horizons of Industry 5.0 through programming and management, control and monitoring software applications, exclusive cutting cycles and integration services.” mep group We are specialized in the design...

Open the catalog to page 2

Distributors and dealers all over the world Countries to which our products are distributed Sawing machines models Material Handling System solutions Customized solutions manufactured annually Machines manufactured annually Euro annual turnover 1000 x 2000 Maximum cutting capacity (mm) “... Believing that digitalization is the key to remaining competitive in the market and improving the quality of products and services, our goal is to promote innovation and sustainable development by putting at the service of our customers solutions that integrate the knowledge gained during the...

Open the catalog to page 3

legend AUTOMATIC CUTTING CYCLE THREE-PHASE POWER SEMI-AUTOMATIC CUTTING CYCLE SINGLE-PHASE POWER CUTTING SPEED SELECTOR INVERTER MOTOR POWER FERROUS MATERIALS CUTTING ANGLE NON-FERROUS MATERIALS CIRCULAR BLADE/BAND SIZE SOLIDS SAWING MACHINE WEIGHT The manufacturer reserves the right to carry out modifications without notice. The published photos may include non-standard details.

Open the catalog to page 4

SHARK THE WIDE RANGE OF BAND SAWING MACHINES This type of sawing machines has been a revolution in the field of steel cutting because they allow the cutting of medium-large materials while maintaining a small footprint. The secret lies in the use of a band blade with variable teeth and a thickness ranging from 1mm to 3mm, thus allowing easier penetration and removal of the material and, at the same time, a proportionate structure of the machine. Thanks to all these characteristics, band sawing machines are extremely flexible in terms of both material sections and their toughness....

Open the catalog to page 5

SHARK 660 CNC HS 4.0, dual-column electromechanical automatic band sawing machine for 0° cuts of structural, stainless and alloy steels, solids and profiles. In addition to the automatic cutting cycle, it can also operate in semi-automatic mode. ABSOLUTE EFFICIENCY EXCEPTIONAL FLEXIBILITY • The two working modes (semi-automatic and automatic ones) allow to perform any kind of cut in the most efficient way. • The bar feeder with single stroke 760 mm is repeatable to cut at any length. • The control allowing to store up to 300 cutting programs, each one with different quantities and lengths,...

Open the catalog to page 6

FLOATING BAR FEEDER VICE Cast-iron structure to absorb vibrations and ensure greater cutting stability and longer blade life. The optional IOT allows to maximize data collection and use them in favor of a better sawing machine cutting performance and longer blade life. The bar feeder vice is self-aligning in order to feed even non-straight bars. MOTION OF THE SAW HEAD ON LINEAR GUIDES Motion of the saw head powered by two brushless motors for an auto-check of all data set/recorded so as to adjust cutting parameters in real-time, counterbalancing through a hydraulic cylinder to give the...

Open the catalog to page 7

MATERIAL LIBRARY FOR THE AUTOMATIC SETTING OF THE BLADE ROTATION SPEED AND HEAD DOWN FEED RATE The material library allows the automatic setting of the blade speed (S) and head down feed rate (F) according to the type of material. From the extendable material library, you can choose the type and the geometry of the material, the hardness and the type of blade. Accordingly, the control sets the right blade speed and head down feed rate. ADAPTATIVE SAW HEAD DOWN FEED RATE Self-regulation in real-time of head down feed rate according to type of material or blade wear.

Open the catalog to page 8

options SHARK OPTION N° 02 options shark Spray mist system Vice pressure regulator Bi-Metal band saw blade Laser projector & work light Supplementary foot pedal control with emergency stop Voltage adaption for 200-220V 50/60Hz three-phase

Open the catalog to page 10

Jaws to reduce remnant max. 30 mm TCT Bi-Metal band saw blade Fixed camera Hydraulic overhead bundlings 350x350 mm Folding back doors Hydraulic overhead bundlings max. 460x460 mm Powered dredging chip conveyor Band saw blade deviation device Digital angle display Jaws to reduce remnant max. 25 mm Hydraulic POP-UP roller left options shark

Open the catalog to page 11

options shark Hydraulic POP-UP roller right Bar sensors to optimize remnant CB 6001 - Automatic chute loading mazagine Bandsaw upgrade to 41 mm blade (in place of the standard blade of 34mm) Hydraulic overhead bundlings for bundle cutting max. 660x660 mm Bandsaw upgrade to 41 mm blade (in addition to the standard blade of 34mm) Retractable fixed vice jaw Adapter for unloading table Kit blade speed 200 m/min (34-mm band) Hydraulic overhead bundling for bundle cutting max. 510x180 mm Kit blade speed 200 m/min (41-mm band) Unloading table adapter Hydraulic overhead bundlings equipped with vice...

Open the catalog to page 12

Blade-guide heads coolant flow control device Loading table adapter with motorized sliding rollers Remnant optimization kit (bar remnant held inside the cutting vice - good piece in the outfeed) Stainless steel belt chip conveyor Wi-Fi remote service Kit for chip conveyor assembly on the left Adapter for loading table Adaption of voltage different from V.400-415 50Hz and V.480 60Hz Adapter for unloading table with support Adapter for loading table with support OPTION N° 130 Unloading table adapter with motorized sliding rollers options shark

Open the catalog to page 13

conveyors for sawing machines KK MOTORIZED ROLLER CONVEYORS SHARK 350 CNC HS 4.0 SHARK 460 KONNECT conveyors for sawing machines

Open the catalog to page 14

• it requires a control ADDITIONAL SUPPORT TRAY COOLANT RECOVERY HYDRAULIC SQUARING VICE ADJUSTABLE VERTICAL ROLLER HEAVY-DUTY VERTICAL ROLLER TWO SETS OF VERTICAL ROLLERS VERTICAL ROLLER options idler conveyors TRUCK & TROLLEY CROSS TRANSFER CHAIN CROSS TRANSFER MEASURING STOP DEVICE FLASH MEASURING STOP DEVICE R4 STAGING SKIDS SAFETY FILLER PLATES MEASURING STOP DEVICE R3

Open the catalog to page 15All MEP catalogs and technical brochures

-

VELOCEX 175

1 Pages

-

VELOCEX 150

1 Pages

-

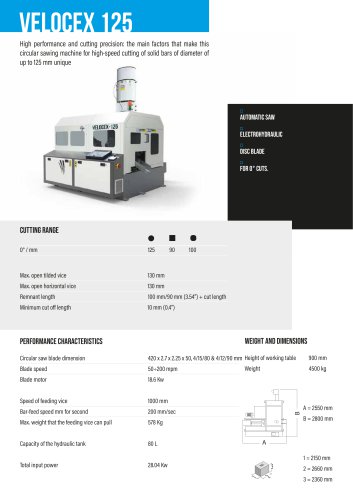

VELOCEX 125

1 Pages

-

VELOCEX 100

1 Pages

-

VELOCEX 80

1 Pages

-

VELOCEX 65

1 Pages

-

VELOCEX LINE

20 Pages

-

TIGER 402 CNC HR 4.0 RC

1 Pages

-

TIGER 402 CNC HR 4.0

1 Pages

-

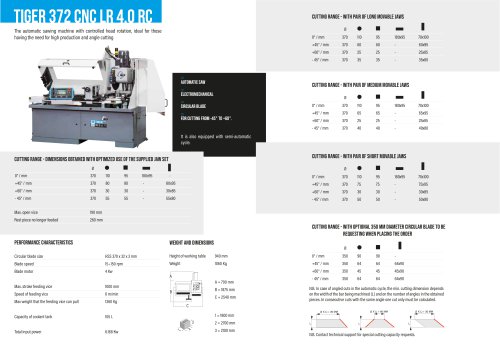

TIGER 372 CNC LR 4.0 RC

1 Pages

-

TIGER 372 CNC LR 4.0

1 Pages

-

TIGER 352 NC 5.0

1 Pages

-

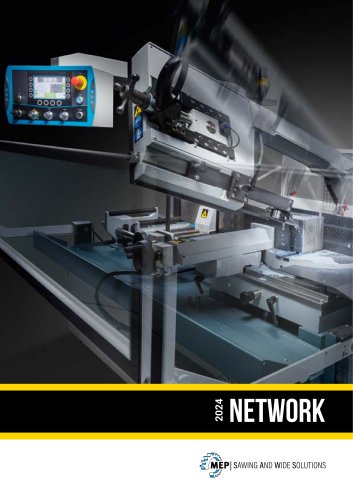

2024 NETWORK - TIGER 352 NC 5.0

22 Pages

-

TIGER 372 SX EVO

1 Pages

-

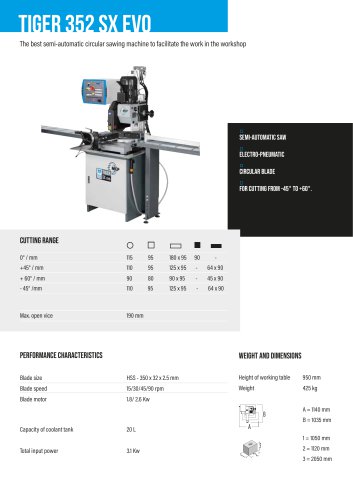

TIGER 352 SX EVO

1 Pages

-

2024 NETWORK - TIGER 352 SX EVO

20 Pages

-

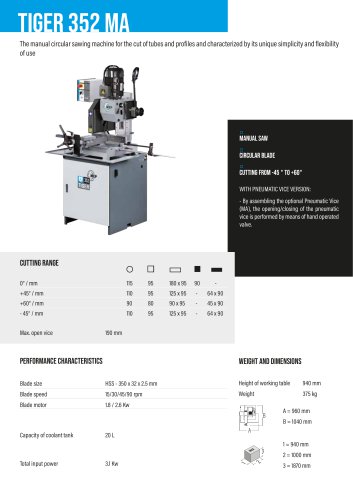

TIGER 352 MA

1 Pages

-

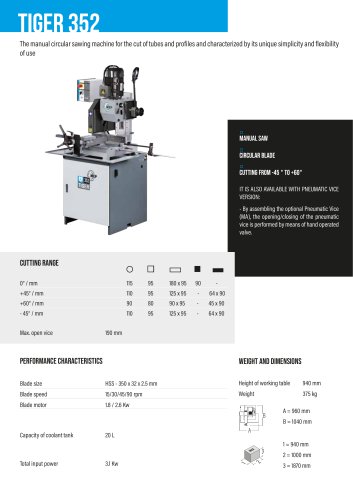

TIGER 352

1 Pages

-

COBRA 352 NC 5.0

1 Pages

-

2024 NETWORK - COBRA 352 NC 5.0

22 Pages

-

COBRA 352 SX EVO

1 Pages

-

2024 NETWORK - COBRA 352 SX EVO

20 Pages

-

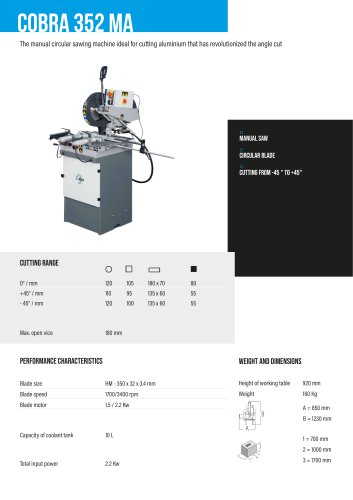

COBRA 352 MA

1 Pages

-

2024 NETWORK - COBRA 352 MA

20 Pages

-

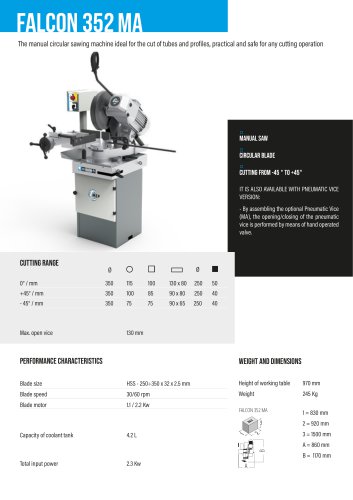

FALCON 352 MA

1 Pages

-

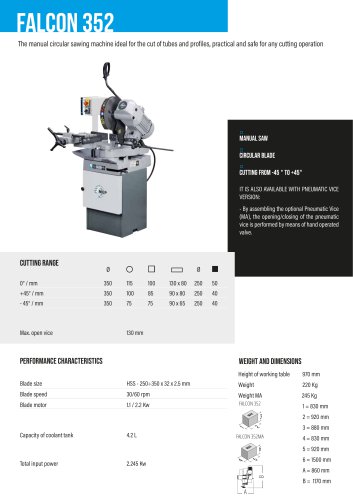

FALCON 352

1 Pages

-

SHARK 660 CNC HS 4.0

1 Pages

-

SHARK 460 KONNECT

1 Pages

-

SHARK 350 CNC HS 4.0

1 Pages

-

SHARK 350 NC HS 5.0

1 Pages

-

SHARK 230-1 NC HS 5.0

1 Pages

-

SHARK 332 RC KONNECT

1 Pages

-

SHARK 332-1 NC 5.0

1 Pages

-

SHARK 331-1 NC 5.0 SPIDER

1 Pages

-

SHARK 281 NC 5.0

1 Pages

-

2024 NETWORK - SHARK 281 NC 5.0

24 Pages

-

THOR 860

1 Pages

-

THOR 660

1 Pages

-

THOR 560

1 Pages

-

THOR 450

1 Pages

-

2023 THOR Line

28 Pages

-

SHARK 652 SXI H 5.0 AUTO

1 Pages

-

SHARK 652 SXI H 5.0

1 Pages

-

SHARK 512 SXI EVO

1 Pages

-

SHARK 452-1 SXI EVO

1 Pages

-

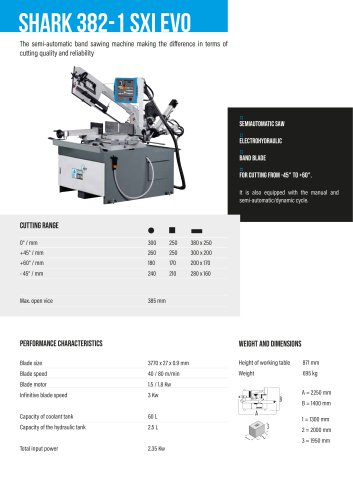

SHARK 382-1 SXI EVO

1 Pages

-

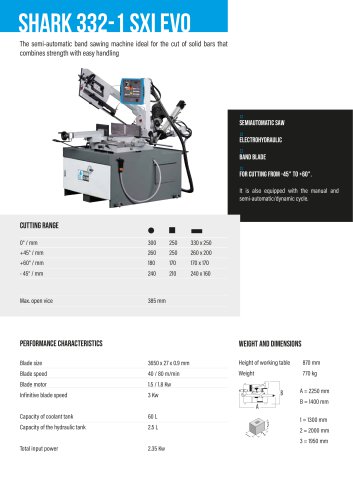

SHARK 332-1 SXI EVO

1 Pages

-

SHARK 282 SXI EVO

1 Pages

-

2024 NETWORK - SHARK 282 SXI EVO

22 Pages

-

SHARK 281 SXI EVO

1 Pages

-

2024 NETWORK - SHARK 281 SXI EVO

22 Pages

-

SHARK 332-1 CCS

1 Pages

-

2024 NETWORK - SHARK 332-1 CCS

22 Pages

-

SHARK 282 CCS MA

1 Pages

-

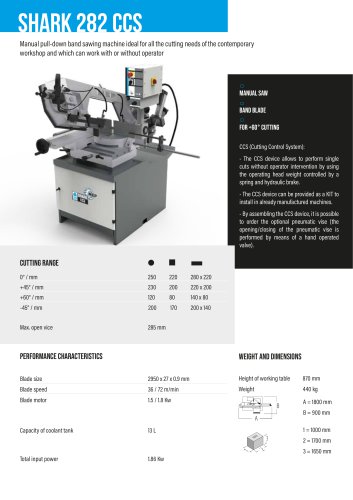

SHARK 282 CCS

1 Pages

-

SHARK 282

1 Pages

-

2024 NETWORK - SHARK 282

22 Pages

-

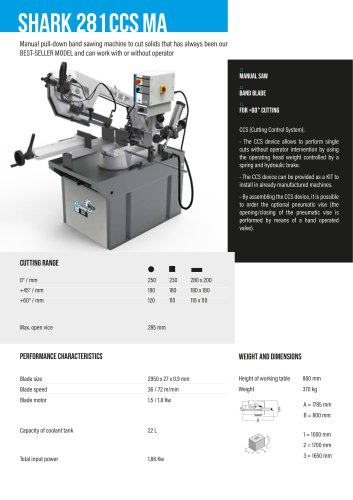

SHARK 281 CCS MA

1 Pages

-

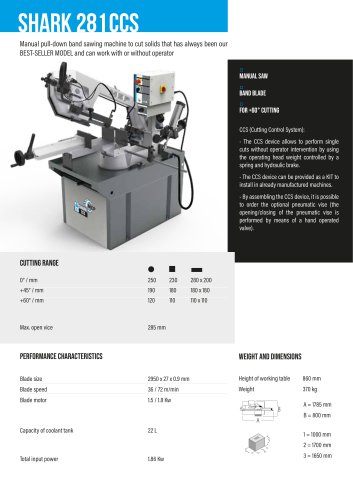

SHARK 281 CCS

1 Pages

-

SHARK 281

1 Pages

-

2024 NETWORK - SHARK 281

24 Pages

-

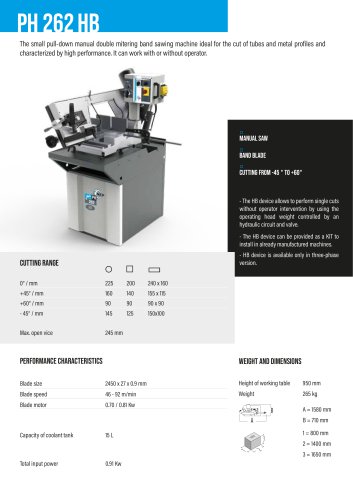

PH 262 HB

1 Pages

-

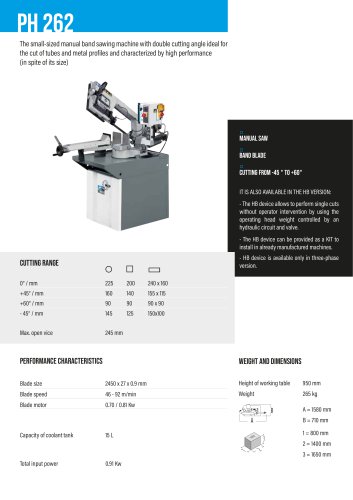

PH 262

1 Pages

-

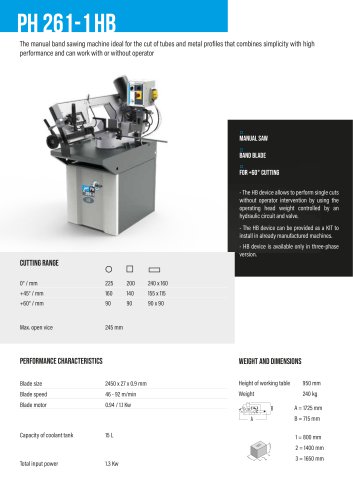

PH 261-1 HB

1 Pages

-

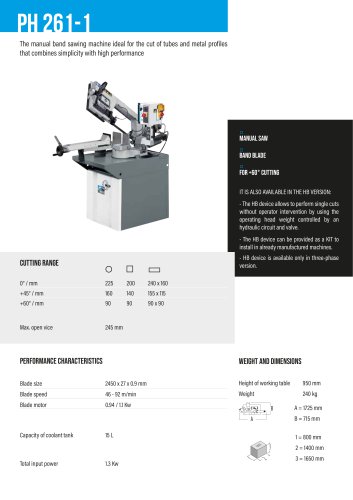

PH 261-1

1 Pages

-

PH 211-1 HB

1 Pages

-

PH 211-1

1 Pages

Archived catalogs

-

THOR LINE

20 Pages

-

SMV 3000

1 Pages

-

SMV 3000 PRO

1 Pages

-

CB 6001

2 Pages

-

Industry

36 Pages

-

Network - GENERAL CATALOGUE 2014

80 Pages

-

Catalogue MEP

88 Pages