Website:

MEP

Website:

MEP

Group: MEP GROUP

Catalog excerpts

THOR MINIMUM USE OF RESOURCES TO MAXIMIZE PROFIT | SAWING AND WIDE SOLUTIONS

Open the catalog to page 1

SEMI-AUTOMATIC DOUBLE COLUMN 0° CUTS BAND SAWING MACHINES SIMPLE AND POWERFUL WITH A HEAVY-DUTY HEART FERROUS & NON-FERROUS MATERIALS Best solution for tube cutting up to 450 mm. Best solution for tube cutting up to 560 mm. Best solution for tube cutting up to 660 mm. Best solution for tube cutting up to 860 mm. Best solution for tube cutting up to 1020 mm.

Open the catalog to page 3

0° CUTS FERROUS & NON-FERROUS MATERIALS SEMI-AUTOMATIC DOUBLE COLUMN BAND SAWING MACHINES SOLID & STRUCTURAL ROUND, SQUARE, RECTANGULAR, HOLLOW TUBES

Open the catalog to page 4

> standard features ▶ Variable vice pressure ▶ Variable vice pressure ▶ Laser beam ▶ Head feed rate on display ▶ Touch screen ▶ Hydraulic blade guide > OPTIONS ▶ Hydraulic bundle clamping ▶ Hydraulic bundle clamping for maximum cutting capacity ▶ 3° canted head ▶ Mist lubrication ▶ Power transformer for voltage different than V.400-415 50Hz ▶ Bi-metal blade ▶ Laser beam

Open the catalog to page 5

THOR LINE TECHNICAL FEATURES > TECHNICAL FEATURES THOR 450 Minimum cut length (without bundle) Minimum clamping Max. vertical open vice Blade speed Blade motor Hydraulic unit motor Shipping dimensions Hydraulic bundle clamping Hydraulic bundle clamping for maximum cutting capacity Hydraulic bundle clamping Hydraulic bundle clamping for maximum cutting capacity PERFORMANCE CHARACTERISTICS Band saw blade dimension

Open the catalog to page 8

TECHNICAL FEATURES THOR LINE

Open the catalog to page 9

THOR LINE > SAW HEAD ▶ Built in coolant tank powered with high flow coolant pump and flow nozzle with tap control to clean better the blade, thus granting a longer life. ▶ Hydraulic blade tensioning system keeps the tensioning constant during the cut. ▶ Hydraulic powered cleaning wire brush to clean better the blade, thus granting a longer life. ▶ Automatic machine stop if blade breaks. ▶ Auto-setting of saw head height. ▶ The automatic alignment of the front blade head guide jointed to the cutting vice reduces setting time independently from the material size. ▶ Infinitely variable...

Open the catalog to page 10

Saw head moving on linear guides with preloaded ball screw slides that grants both a mechanical vibration reduction during the cut and greater cutting stability. Set of hard metal blade guide plates, equipped with anti-vibration rollers and extremely wear resistant, that helps to grant longer blade life and cutting stability. Blade moves on graded cast iron wheels. Driver wheel on specially designed spindle of worm reduction gear box. Working light. THOR LINE

Open the catalog to page 11

THOR LINE MATERIAL CLAMPING > MATERIAL CLAMPING ▶ Split vice for rigid clamping and burr free cuts: split main vice helps in holding the job on both sides of cutting. ▶ Hydraulically operated main vice with double acting hydraulic cylinder. ▶ Blade guide united with vice thus granting a self-adjustment according to the size of the material. ▶ Hydraulic vice clamps the material both in the infeed and outfeed side of the blade, thus allowing to safely execute precise and burr-free cuts. ▶ Loading side equipped with roller conveyor and vertical rollers to place and contain pieces

Open the catalog to page 12

THOR LINE > STRUCTURE ▶ Ergonomically designed machine provides wide space for blade change, regular check-up and preventive maintenance. ▶ Heavy-duty steel welded structure - torsion free construction to cut vibrations thus giving max stability to the sawing machine and longer blade life

Open the catalog to page 14

THOR LINE > TECHNOLOGY ▶ Automatic head down feed regulator through infinitely variable feed control valve that adjusts in automatic saw head down feed rate according to size and hardness of material. ▶ The chip auger ensures better operating conditions and reduces processing time by preventing passive working times of the production process for the manual waste removal. ▶ Auto-setting of saw head heig

Open the catalog to page 18

Inverter for infinite variable blade speed allows to adjust the saw blade rotation speed according to the type of material. Electric motor is coupled to the gearbox. Saw blade speed change through inverter for optimum productivity and tool life. Latest generation hydraulic power pack with high efficiency and low consumption. Separate hydraulic power pack and tank for easy maintenance. Fast approach device grants a quick descent of the saw head very close to the material, thus reducing the cycle time and blade damages indipendently of the size of the material. THOR LINE

Open the catalog to page 19

THOR LINE > CONTROL ▶ User friendly programming of cutting cycles. ▶ Electrical control panel with hmi and push buttons, emergency stop button, main isolator, PLC, VFD, step down transformer, auxiliary contractor, cable connector and connector with fuses. ▶ Hydraulic valve and feed pressure adjustment valves are fitted on control panel for easy operation. Screen visibility and sharpness Program uploading and downloading Analog and Modbus both Modbus only Functions / Capabilities Head feed rate on display Colour Download without laptop at site by SD card Communication Saw motor speed set...

Open the catalog to page 21

MEP’s passionate team of designers and technical experts use the latest mechanical design software to be at the forefront of metal cutting technology and to choose the most innovative and advanced solutions to all possible needs in metal cutting. DESIGN AND PRODUCTION OF CUSTOM CUTTING LINES MEP’s technical staff are able to design and build custom cutting machines and equipments to meet all possible needs. DO YOU NEED A SAW? WE MAKE YOUR OWN SAW

Open the catalog to page 22

SPARE PARTS SERVICE & SUPPORT The Mep After Sale Service supports Customers with a range of services that for years have been one of the Company’s excellence. Our technical staff is always ready to guarantee you the best assistance in the identification of the spare parts, even for machines out of production, and shipping by the fastest couriers within 24-72 hours after placing the order. Moreover, storage and modern logistics ensure that our spare parts warehouse is constantly optimized in order to guarantee maximum availability. MAINTENANCE PLANS A regular maintenance has several...

Open the catalog to page 24All MEP catalogs and technical brochures

-

VELOCEX 175

1 Pages

-

VELOCEX 150

1 Pages

-

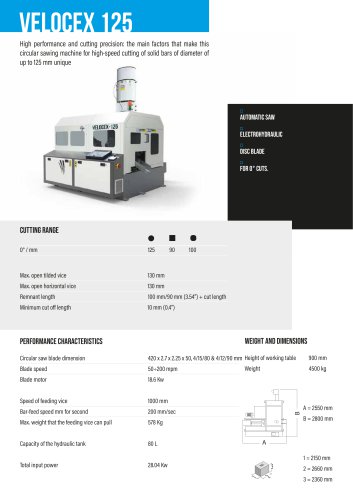

VELOCEX 125

1 Pages

-

VELOCEX 100

1 Pages

-

VELOCEX 80

1 Pages

-

VELOCEX 65

1 Pages

-

VELOCEX LINE

20 Pages

-

TIGER 402 CNC HR 4.0 RC

1 Pages

-

TIGER 402 CNC HR 4.0

1 Pages

-

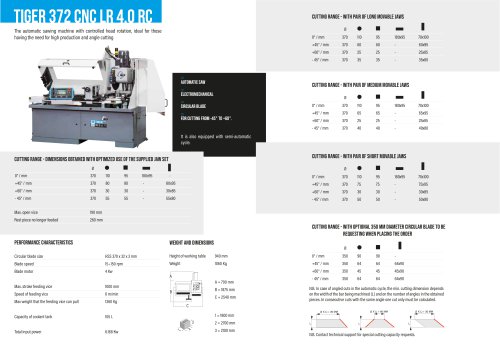

TIGER 372 CNC LR 4.0 RC

1 Pages

-

TIGER 372 CNC LR 4.0

1 Pages

-

TIGER 352 NC 5.0

1 Pages

-

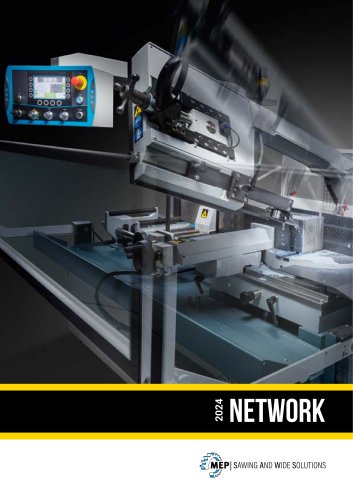

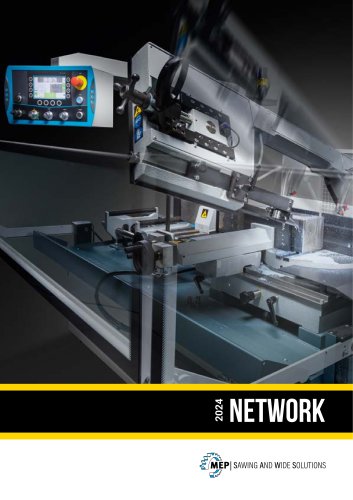

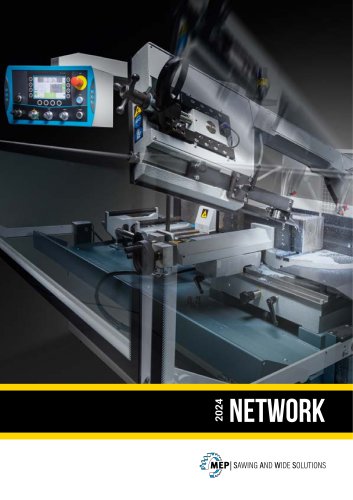

2024 NETWORK - TIGER 352 NC 5.0

22 Pages

-

TIGER 372 SX EVO

1 Pages

-

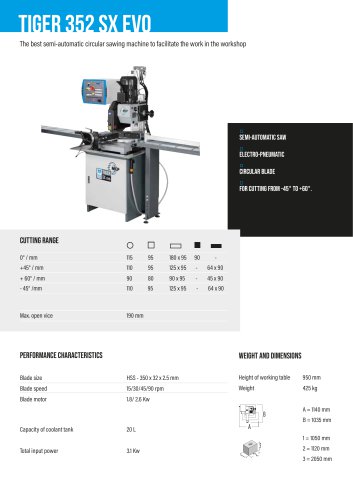

TIGER 352 SX EVO

1 Pages

-

2024 NETWORK - TIGER 352 SX EVO

20 Pages

-

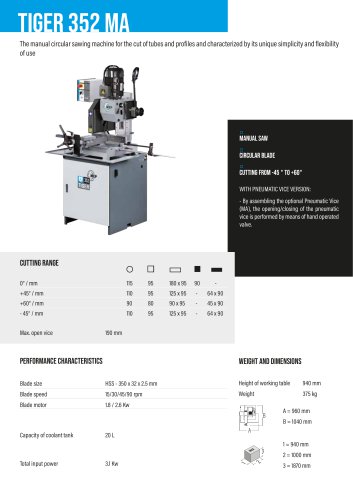

TIGER 352 MA

1 Pages

-

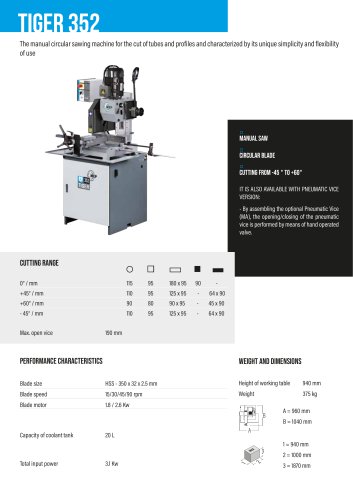

TIGER 352

1 Pages

-

COBRA 352 NC 5.0

1 Pages

-

2024 NETWORK - COBRA 352 NC 5.0

22 Pages

-

COBRA 352 SX EVO

1 Pages

-

2024 NETWORK - COBRA 352 SX EVO

20 Pages

-

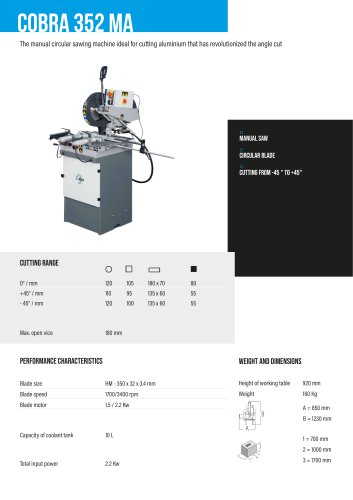

COBRA 352 MA

1 Pages

-

2024 NETWORK - COBRA 352 MA

20 Pages

-

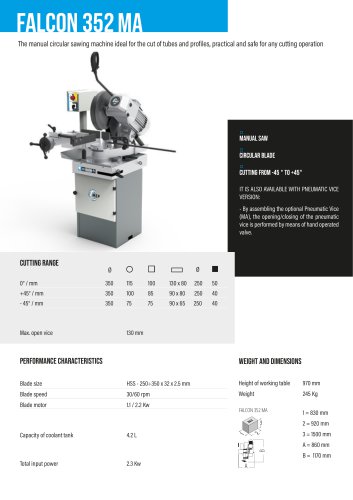

FALCON 352 MA

1 Pages

-

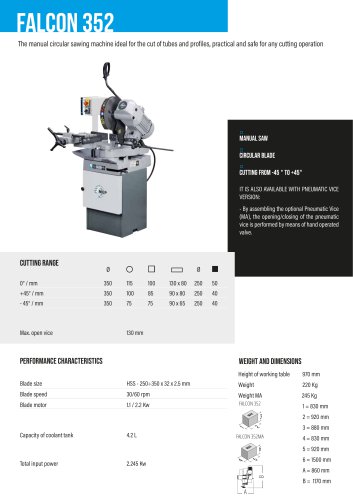

FALCON 352

1 Pages

-

SHARK 660 CNC HS 4.0

1 Pages

-

SHARK 460 KONNECT

1 Pages

-

SHARK 350 CNC HS 4.0

1 Pages

-

SHARK 350 NC HS 5.0

1 Pages

-

SHARK 230-1 NC HS 5.0

1 Pages

-

SHARK 332 RC KONNECT

1 Pages

-

SHARK 332-1 NC 5.0

1 Pages

-

SHARK 331-1 NC 5.0 SPIDER

1 Pages

-

SHARK 281 NC 5.0

1 Pages

-

2024 NETWORK - SHARK 281 NC 5.0

24 Pages

-

THOR 860

1 Pages

-

THOR 660

1 Pages

-

THOR 560

1 Pages

-

THOR 450

1 Pages

-

SHARK 652 SXI H 5.0 AUTO

1 Pages

-

SHARK 652 SXI H 5.0

1 Pages

-

SHARK 512 SXI EVO

1 Pages

-

SHARK 452-1 SXI EVO

1 Pages

-

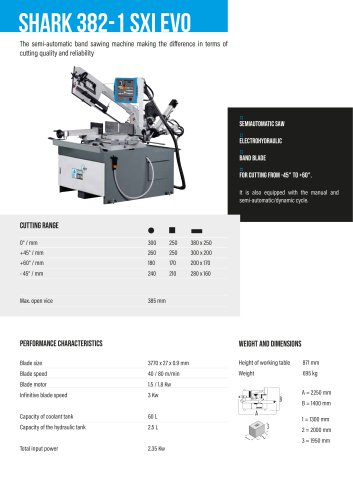

SHARK 382-1 SXI EVO

1 Pages

-

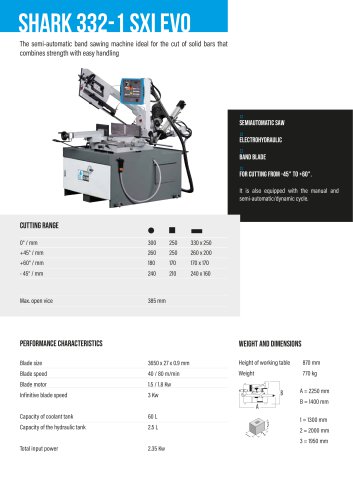

SHARK 332-1 SXI EVO

1 Pages

-

SHARK 282 SXI EVO

1 Pages

-

2024 NETWORK - SHARK 282 SXI EVO

22 Pages

-

SHARK 281 SXI EVO

1 Pages

-

2024 NETWORK - SHARK 281 SXI EVO

22 Pages

-

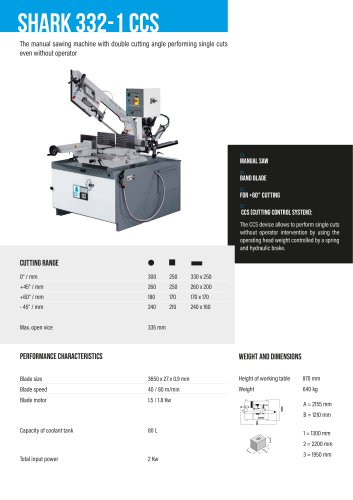

SHARK 332-1 CCS

1 Pages

-

2024 NETWORK - SHARK 332-1 CCS

22 Pages

-

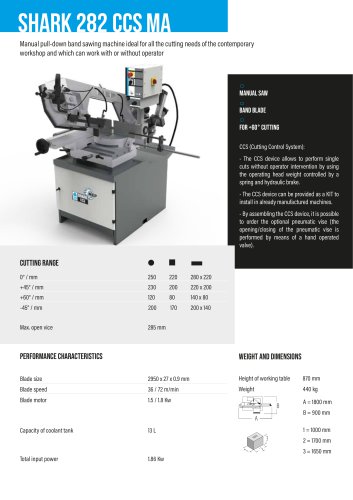

SHARK 282 CCS MA

1 Pages

-

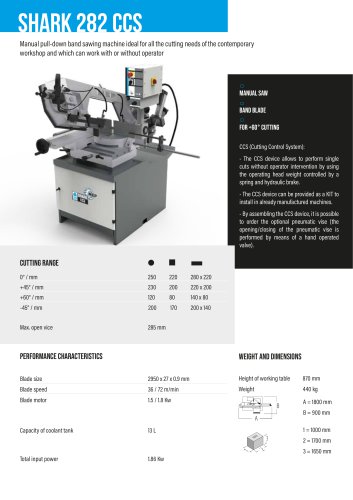

SHARK 282 CCS

1 Pages

-

SHARK 282

1 Pages

-

2024 NETWORK - SHARK 282

22 Pages

-

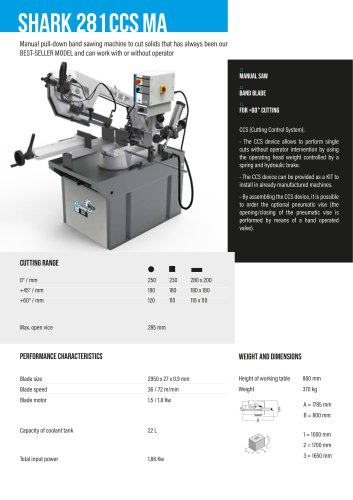

SHARK 281 CCS MA

1 Pages

-

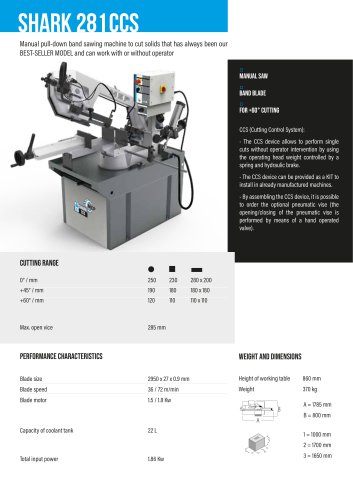

SHARK 281 CCS

1 Pages

-

SHARK 281

1 Pages

-

2024 NETWORK - SHARK 281

24 Pages

-

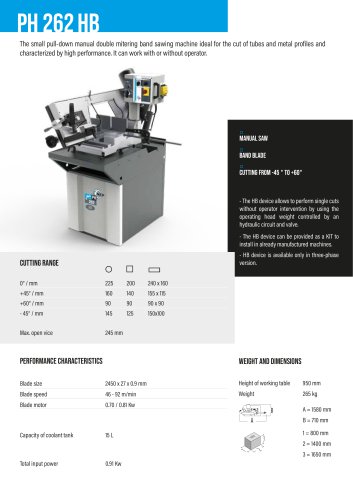

PH 262 HB

1 Pages

-

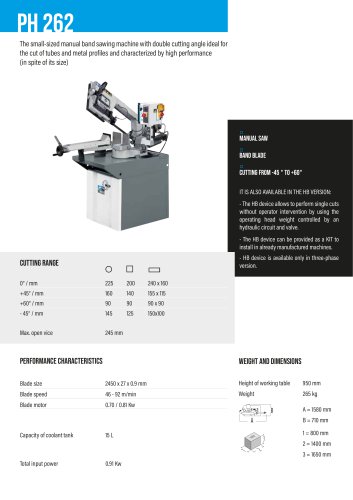

PH 262

1 Pages

-

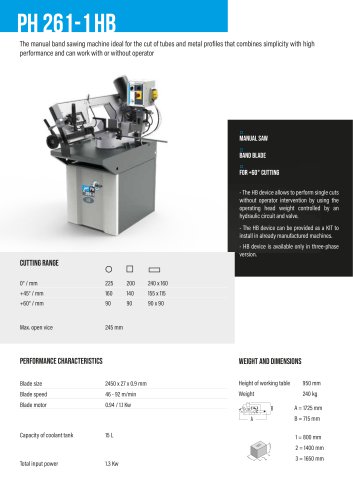

PH 261-1 HB

1 Pages

-

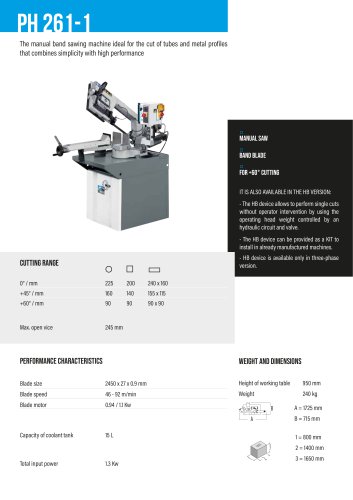

PH 261-1

1 Pages

-

PH 211-1 HB

1 Pages

-

PH 211-1

1 Pages

Archived catalogs

-

THOR LINE

20 Pages

-

SMV 3000

1 Pages

-

SMV 3000 PRO

1 Pages

-

CB 6001

2 Pages

-

Industry

36 Pages

-

Network - GENERAL CATALOGUE 2014

80 Pages

-

Catalogue MEP

88 Pages