Website:

MECON

Website:

MECON

Catalog excerpts

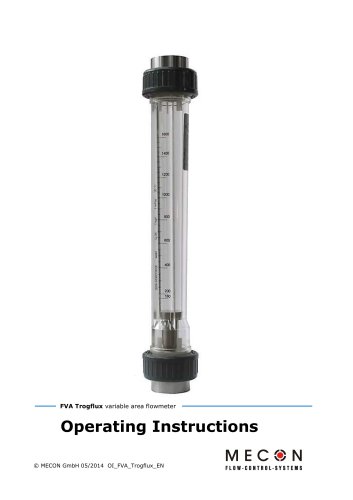

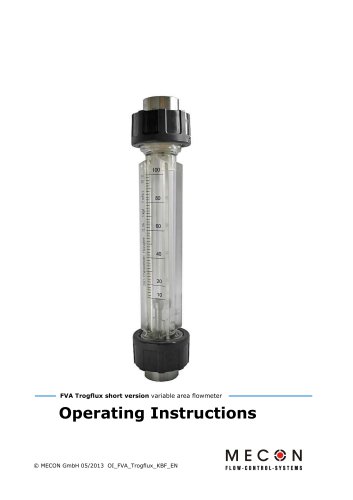

FVA Trogflux variable area flowmeter Operating Instructions © MECON GmbH 05/2014 OI_FVA_Trogflux_EN

Open the catalog to page 1

All rights reserved. It is prohibited to reproduce this document, or any parts thereof, without prior written authorization of MECON Flow Control Systems GmbH. Subject to change without notice. Copyright 2014 by MECON Flow Control Systems GmbH - Röntgenstraße 105 - 50169 Kerpen Operating instructions FVA Trogflux 05/2014 OI_FVA_Trogflux_EN

Open the catalog to page 2

Operating instructions FVA Trogflux 05/2014 OI_FVA_Trogflux_EN

Open the catalog to page 3

Safety Instructions 1 Safety Instructions 1.1 Intended use The FVA Trogflux variable area meters are used to measure the volume of transparent liquids and gases into closed piping. The variable area meters can also be used for flow monitoring if they are equipped with one or more switching contacts. Standard scales are available for liquids with a density of 1 kg/l (62.43 lb/cu.ft). The scales must be recalculated for all other media depending on the physical characteristics. The devices are particularly suitable for the measurement of: • Clear liquids Warning ! The operator of these...

Open the catalog to page 4

Safety Instructions The manufacturer certifies that the device FVA Trogflux meets all statutory requirements of the following EC directives by applying the CE marking: • Pressure equipment directive 97/23/EC The most hazardous permissable media are - for gases: fluids of group 2 for liquids: fluids of group 1. 1.3 Safety instructions from the manufacturer Disclaimer The manufacturer will not be liable for any damage resulting from the use of its product, including, but not limited to direct, indirect, incidental, punitive and consequential damages. Any product purchased from the...

Open the catalog to page 5

2 Start-up 2.1 Standard device When starting up the unit, the following points must be observed: ● Make sure that the actual operating conditions (pressure and temperature) do not exceed the limits specified on the nameplate. Avoid float impact! Therefore it is recommended to start with a closed shut-off valve during commissioning and adjust the operating pressure by opening the valve slowly. In particular, the use of magnetic valves is not recommended in this case. When measuring liquids, make a careful release of the pipeline to prevent pressure peaks by gas bubbles. When commissioning...

Open the catalog to page 6

3 Installation 3.1 Installation instructions Information ! All instruments are carefully checked for proper function before shipment. Check immediately on receipt, the outer packing carefully for damage or signs of improper handling. Report damage to the carrier and your competent sales staff. In such cases, a description of the defect, the type and the serial number of the device is indicated. Information ! Unpack the unit carefully to avoid damage. Information ! Check the completeness of the delivery by using the packing list. Check the name plate, if the delivered flow meter is according...

Open the catalog to page 7

4 Service 4.1 Storage Store the device dry and dust free. Avoid direct exposure to the sun and heat. Avoid external loads on the device. The admissible storage temperature for standard devices with electrical components: -40 … +70 °C. 4.2 Maintenance The devices are built for low maintenance operations but periodically the flowmeters should be inspected for signs of corrosion, mechanical wear as well as damage to the fitting and the display unit. We advice to carry out inspections at least once a year. For a detailed inspection and cleaning the device must be removed from the piping....

Open the catalog to page 8

Device Description 5 Device Description 5.1 Scope of delivery 1 flowmeter FVA Trogflux 2 Operating instructions 3 Certificates (optional) Information ! Please check the delivery for completeness using the packing list. Standard device with PVC adhesive bushing Standard device with female thread The main components of the FVA Trogflux are the measuring tube made of plastics, the float and the connecting parts. A scale is printed on the flow tube (eg in l / h). The actual flowrate is read at Operating instructions FVA Trogflux 05/2014 OI_FVA_Trogflux_EN

Open the catalog to page 9

Device Description the position of the largest diameter of the float. For process monitoring and control, the unit can be equipped with one or more contacts. Special features • Product scales for liquids and gases Low cost plastic version Short delivery times for standard versions 5.3 Nameplate Important ! Please refer to the device nameplate to ensure that the device is built according to your order. Check particularly for the correct supply voltage. Code number TS Medium Maximum temperature of the medium Maximum pressure of the medium Device specific code number Maximum pressure of the...

Open the catalog to page 10

Description Code Description Code The descripion code consists of the following elements: Plastic material for measuring cone Gasket material 3 Measuring cone size AC 125 BC Float material Stainless steel (Mat.-No. 1.4305) Stainless steel (Mat.-No. 1.4571/1.4404) Stainless steel Mat.-No. 1.4571/SV/316Ti PVDF, weighted Operating instructions FVA Trogflux 05/2014 OI_FVA_Trogflux_EN

Open the catalog to page 11

Description Code Connection material PVC / Standard, for plastic tubes only Cast iron (only for G½, G1 , G2) Stainless steel Connection form Adhesive bushing (only made of PVC) Female thread NPT (NPT ANSI B1.20.1) 7 Connection size A Adhesive bushing B 8 Contacts (only with magnetic floats) A Without contact C Contact K18/A (closes on falling below the limit) Contact K18/B (closes on exceeding the limit) Float version Standard With magnet Other versions With calbration certificate Measured medium: always required, specify in plain text (Medium, Measuring range, Device range; Density;...

Open the catalog to page 12

Measuring ranges for liquids 7 Measuring ranges for liquids Standard Measuring range for liquids (ρ=1 kg/l, Viscosity 1mPa⋅s) ρ ⋅ Measuring cone Maximum measuring range for the selected floats PVC Female Adhesive thread bushing [mm] with magnet with magnet weighted Stainless steel Pressure loss float Stainless steel Stainless steel (Connections in brackets are not standard) 1) guided float Measuring cone made of Trogamid Measuring cone made of Polysulfon Operating instructions FVA Trogflux 05/2014 OI_FVA_Trogflux_EN

Open the catalog to page 13All MECON catalogs and technical brochures

-

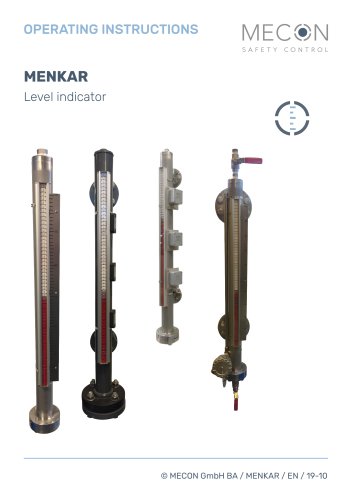

MENKAR KK

28 Pages

-

MENKAR

28 Pages

-

Turbo-Lux® 3

20 Pages

-

N4

20 Pages

-

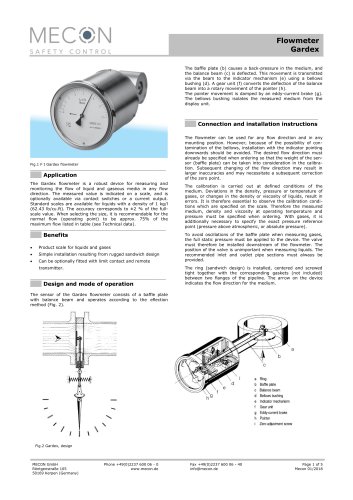

Gardex

5 Pages

-

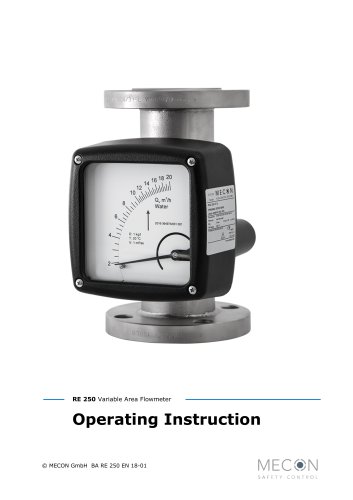

RE 250

32 Pages

-

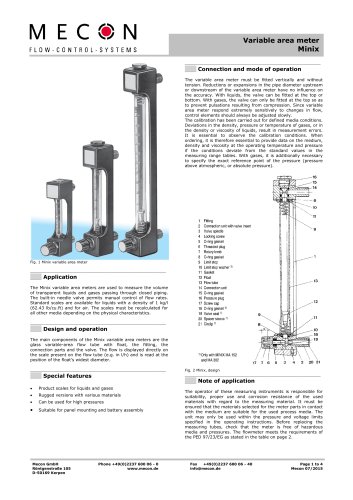

Minix

4 Pages

-

Tubux M30

20 Pages

-

KBF

20 Pages

-

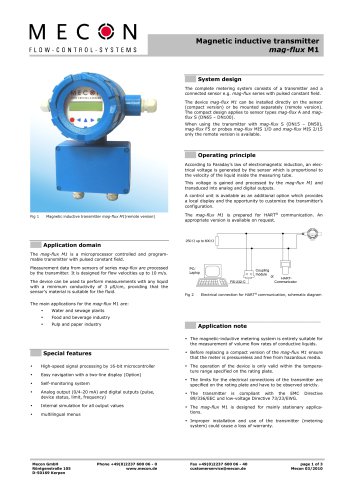

mag-flux M1

35 Pages

-

mag-flux F5

4 Pages

-

mag-flux A

9 Pages

-

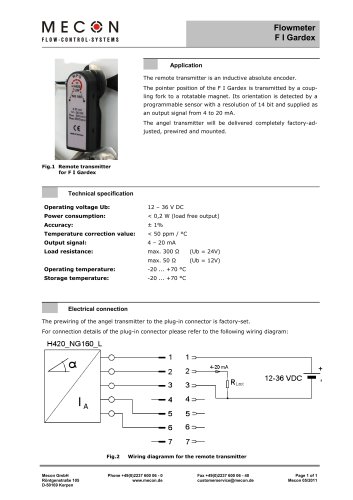

Flowmeter F I Gardex

1 Pages

-

Product catalogue

24 Pages