Website:

MECON

Website:

MECON

Catalog excerpts

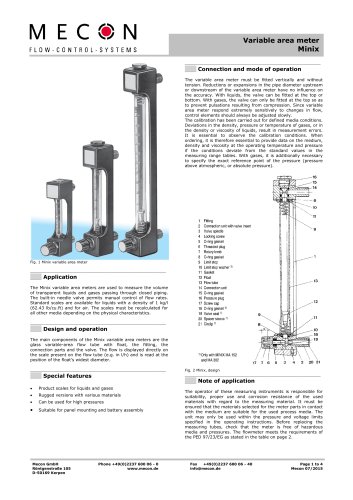

Variable area meter Minix ___ Connection and mode of operation ___ Design and operation Fig. 1 Minix variable area meter The Minix variable area meters are used to measure the volume of transparent liquids and gases passing through closed piping. The built-in needle valve permits manual control of flow rates. Standard scales are available for liquids with a density of 1 kg/l (62.43 lb/cu.ft) and for air. The scales must be recalculated for all other media depending on the physical characteristics. ___ Special features The main components of the Minix variable area meters are the glass variable-area flow tube with float, the fitting, the connection parts and the valve. The flow is displayed directly on the scale present on the flow tube (e.g. in l/h) and is read at the position of the float's widest diameter. Product scales for liquids and gases Rugged versions with various materials Can be used for high pressures Suitable for panel mounting and battery assembly Mecon GmbH Röntgenstraße 105 D-50169 Kerpen The variable area meter must be fitted vertically and without tension. Reductions or expansions in the pipe diameter upstream or downstream of the variable area meter have no influence on the accuracy. With liquids, the valve can be fitted at the top or bottom. With gases, the valve can only be fitted at the top so as to prevent pulsations resulting from compression. Since variable area meter respond extremely sensitively to changes in flow, control elements should always be adjusted slowly. The calibration has been carried out for defined media conditions. Deviations in the density, pressure or temperature of gases, or in the density or viscosity of liquids, result in measurement errors. It is essential to observe the calibration conditions. When ordering, it is therefore essential to provide data on the medium, density and viscosity at the operating temperature and pressure if the conditions deviate from the standard values in the measuring range tables. With gases, it is additionally necessary to specify the exact reference point of the pressure (pressure above atmospheric, or absolute pressure). The operator of these measuring instruments is responsible for suitability, proper use and corrosion resistance of the used materials with regard to the measuring material. It must be ensured that the materials selected for the meter parts in contact with the medium are suitable for the used process media. The unit may only be used within the pressure and voltage limits specified in the operating instructions. Before replacing the measuring tubes, check that the meter is free of hazardous media and pressures. The flowmeter meets the requirements of the PED 97/23/EG as stated in the table on page 2. Fig. 2 Minix, design ____________________________________________________________ Fax +49(0)2237 600 06 - 40 info@mecon.de

Open the catalog to page 1

Variable area meter Minix ___ Technical Data ___ Dimensional drawings ____________________________________________________________ Application Mode of operation Measuring principle Input Flow Pressure limit Rated operating conditions Ambient conditions Temperature limits Medium conditions • Accuracy • Measuring range • Dimensions for meas. variable Design Connections Material • Flow tube • Connection • Gasket • Fitting Weight • MA 70 • MA 151 • MA 152 • MA 301 • MA 302 Certificates and approvals Classification according to PED 97/23/EC See page 1 See page 1 Float Class 2,5 (according to...

Open the catalog to page 2

___ Measuring range ____________________________________________________________ Note: With liquids, only available for media with viscosity = 1 mPa∙s (1cp) ! Type Mecon GmbH Röntgenstraße 105 D-50169 Kerpen Measuring range Liquids ρ = 1 kg/l (62,43 lb/cu.ft), viscosity = 1 mPa∙s (1cp) l/h Variable area meter Minix Gases air at pabs = 1,013 bar (14,69 psi) and T=0°C (32°F), ρ=1,293 kg/m³, v=0,0181 mPa.s l/h Float, aluminium

Open the catalog to page 3

Variable area meter Minix ___ Selection and ordering data for liquids MA 70 Gasket mat er ial • FKM C o nnect io n t yp e • male t hread DIN, 1.4571/ 316Ti • male t hread NPT, 1.4571/ 316Ti • hose bushing, 1.4571/ 316Ti F ur t her d esi g ns Please add " - Z " to order no. and specif y order code ρ = 1 kg/l (62,43 lbs/cu.ft), viscosity = 1 mPa.s (1cp) M edium (always required if density is not 1 kg/ l if density is not 1 kg/ l (62,43 lb/ cu.f t ) specif y in plain t ext M edium, measuring range, dimension, densit y wit h dimension, viscosity with dimension, operat ing t emperat ure, operat...

Open the catalog to page 4All MECON catalogs and technical brochures

-

MENKAR KK

28 Pages

-

MENKAR

28 Pages

-

Turbo-Lux® 3

20 Pages

-

N4

20 Pages

-

Gardex

5 Pages

-

RE 250

32 Pages

-

Tubux M30

20 Pages

-

KBF

20 Pages

-

Trogflux

21 Pages

-

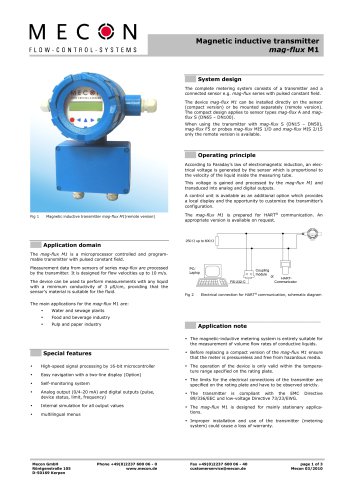

mag-flux M1

35 Pages

-

mag-flux F5

4 Pages

-

mag-flux A

9 Pages

-

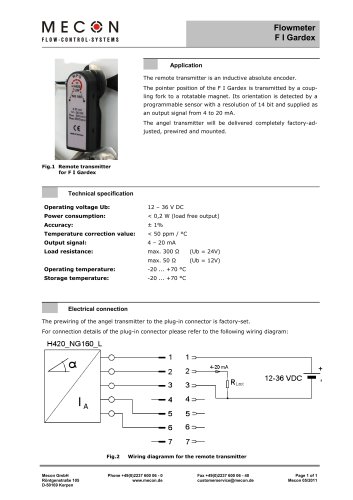

Flowmeter F I Gardex

1 Pages

-

Product catalogue

24 Pages