Website:

MECON

Website:

MECON

Catalog excerpts

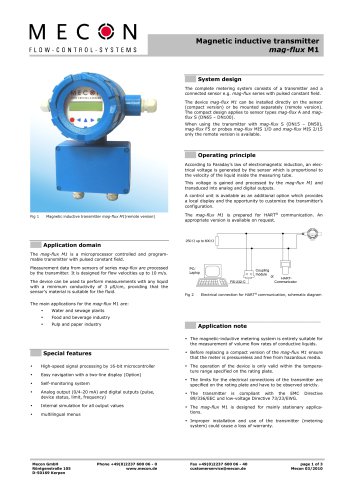

Magnetic inductive transmitter mag-flux M1 System design The complete metering system consists of a transmitter and a connected sensor e.g. mag-flux series with pulsed constant field. The device mag-flux M1 can be installed directly on the sensor (compact version) or be mounted separately (remote version). The compact design applies to sensor types mag-flux A and magflux S (DN65 – DN100). When using the transmitter with mag-flux S (DN15 – DN50), mag-flux F5 or probes mag-flux MIS 1/D and mag-flux MIS 2/15 only the remote version is available. Operating principle According to Faraday’s law of electromagnetic induction, an electrical voltage is generated by the sensor which is proportional to the velocity of the liquid inside the measuring tube. This voltage is gained and processed by the mag-flux M1 and transduced into analog and digital outputs. A control unit is available as an additional option which provides a local display and the opportunity to customize the transmitter’s configuration. Fig 1 Magnetic inductive transmitter mag-flux M1(remote version) The mag-flux M1 is prepared for HART® communication. An appropriate version is available on request. Application domain The mag-flux M1 is a microprocessor controlled and programmable transmitter with pulsed constant field. Measurement data from sensors of series mag-flux are processed by the transmitter. It is designed for flow velocities up to 10 m/s. The device can be used to perform measurements with any liquid with a minimum conductivity of 3 S/cm, providing that the sensor’s material is suitable for the fluid. Electrical connection for HART® communication, schematic diagram The main applications for the mag-flux M1 are: • Water and sewage plants Food and beverage industry Pulp and paper industry Application note • The magnetic-inductive metering system is entirely suitable for the measurement of volume flow rates of conductive liquids. • Before replacing a compact version of the mag-flux M1 ensure that the meter is pressureless and free from hazardous media. Special features • The operation of the device is only valid within the temperature range specified on the rating plate. High-speed signal processing by 16-bit microcontroller Easy navigation with a two-line display (Option) Self-monitoring system • The limits for the electrical connections of the transmitter are specified on the rating plate and have to be observed strictly. Analog output (0/4-20 mA) and digital outputs (pulse, device status, limit, frequency) • The transmitter is compliant with the EMC 89/336/EEC und low-voltage Directive 73/23/EWG. Internal simulation for all output values multilingual menus • The mag-flux M1 is designed for mainly stationary applications. • Improper installation and use of the transmitter (metering system) could cause a loss of warranty. Mecon GmbH Röntgenstraße 105 D-50169 Kerpen

Open the catalog to page 1

Technical Data Operating conditions Installation conditions See also datasheet of the connected Mode of operation and design Measuring principle magnetic inductive with pulsed constant field (PDC) Magnetic field excitation Internal clock with DC supply Outputs Electrical isolation Current output • Signal - Signal range - Failure signal • Load - Output - for HART communication Communication • Protocol outputs electrically isolated from each other and from the power supply 0 ... 20 mA / 4 ... 20 mA, selectable > 22 mA oder < 3,8 mA, can be switched < 600 Q > 250 Q via analog output with PC...

Open the catalog to page 2

Order codeMagnetic inductive transmitter mag-flux Ml M A G 5 0 4 0 - remote version > compact version Other models • Rating plate in English • Measuring range, specify in plain text • Silicone-free materials • Measuring-point number • Measuring-point description • Stainless steel tag plate Mecon GmbH RontgenstraBe 105 D-50169 Kerpen

Open the catalog to page 3All MECON catalogs and technical brochures

-

MENKAR KK

28 Pages

-

MENKAR

28 Pages

-

Turbo-Lux® 3

20 Pages

-

N4

20 Pages

-

Gardex

5 Pages

-

RE 250

32 Pages

-

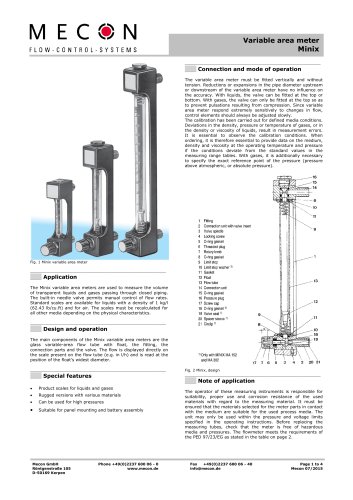

Minix

4 Pages

-

Tubux M30

20 Pages

-

KBF

20 Pages

-

Trogflux

21 Pages

-

mag-flux M1

35 Pages

-

mag-flux F5

4 Pages

-

mag-flux A

9 Pages

-

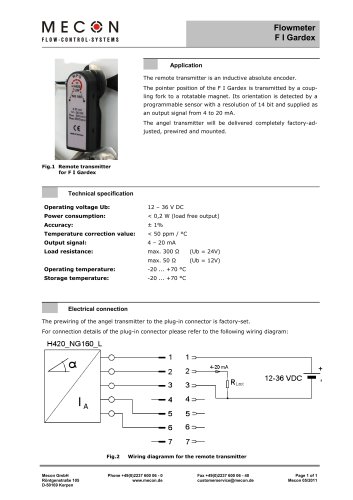

Flowmeter F I Gardex

1 Pages

-

Product catalogue

24 Pages