Website:

MECON

Website:

MECON

Catalog excerpts

Electromagnetic flow Sensor mag-flux A various connection types and materials different materials and process connections o flange: EN, DIN, ANSI, JIS o and other upon request __ Operating note The electromagnetic flow sensor is only intended for measuring the flow of electric conductive, liquid media. The operator of these measuring instruments is responsible for suitability, proper use and corrosion resistance of the used materials with regard to the measuring material. It must be ensured that the materials selected for the meter parts in contact with the medium are suitable for the used process media. Before replacing the measuring tubes, check that the unit is free of hazardous media and is not pressurized. The device may only be used for the pressure and voltage limits specified on the rating plate. The flow meter complies with the requirements of the Pressure Equipment Directive 2014/68/EU. The most hazardous permissible media are the fluids defined in group 1. See page 4 When using flanges made from C22.8 and ST52-3, the lowest permissible temperature is -10 °C (14 °F). Fig. 1 Electromagnetic flow Sensor mag-flux A Electromagnetic flow sensors mag-flux A are precision measuring devices, suitable for determining the flow rate of nearly any electrically conductive fluid, but also for substances such as sludge, pulp and paste. The sensor must not be affected by external loads. The units are designed for predominantly recumbent load. Improper installation or incorrect use of the sensors (units) may null and void any warranty. At the media temperatures indicated below and at DN >300, the permissible max. pressure for PN10 and PN16 is reduced accordingly: Due to the magnetic field, the device can be used to measure flow rates up to 10 m/s (32.8 ft/s) and a minimum conductivity of 20 µS/cm, when using a synchronized static field. Water and sewage plants Chemical and pharmaceutical industry Food and beverage industry Mining, cement and mineral materials Pulp and paper industry Steel industry Energy industry, public utilities The electromagnetic flow sensors mag-flux A are applied mainly in the following industries: The entire measuring device comprises a flow sensor and a dedicated transmitter. Those can be delivered either separately or as a compact unit. If you return mag-flux A sensors back to MECON GmbH, please take note of the "Return equipment Form" which can be found on the Internet at www.mecon.de/en/device-returns/. Without this completed form, no repair or testing can be carried out by MECON GmbH. Installation supplies (gaskets/seals, screws, etc.) are not included with the delivery. The units work on the principle of Faraday’s law of induction, whereby, simply stated, the sensor converts the flow into voltage, proportional to the flow rate. Special features solid welded steel design, therefore rugged and fail-safe signal amplifier inside sensor inside diameter of measuring tube from 15 mm (0.591”) Liner: o hard rubber o soft rubber o PTFE o special lining upon request MECON GmbH Röntgenstraße 105 50169 Kerpen/Germany

Open the catalog to page 1

Electromagnetic flow Sensor mag-flux A __ Basically, the measuring principle does not depend on the flow profile. Ideally, the sensor should be installed in a pipeline with a sufficient straight run, both before and after the measuring point. Experience has shown that an inflow path of 5 x DN and an outflow zone of at least 2 x DN is required. The sensor must be installed in an area of the pipe which will always be filled with media. If a pipeline is not always filled, or in case of an open channel (drainage), the sensor must be installed in a siphon (Fig. 4). Provided that constant...

Open the catalog to page 2

Electromagnetic flow Sensor mag-flux A __ Technical Data Application field Measuring principle Pulsed constant field (DC) Inlet Nominal diameters Process connections special connections Measuring accuracy Error of measurement The mag-flux A sensor with PTFE lining is protected using a protective disc. In order to avoid formation of a vacuum, the sensor should be installed at the lowest point of the pipeline. Do not remove or damage the bead of the lining along the flanges. Information for sensors with soft rubber lining Sensors with soft rubber/neoprene lining are only available from...

Open the catalog to page 3

Electromagnetic flow Sensor mag-flux A __ Classification per Pressure Equipment Directive The devices are designed, based on the directive for fluids of the hazard group Gas 1. The classification varies and depends on the design. Please see table below. For flange material C22.8 (1.0460) and ST52-5 (1.0570) a minimum temperature of -10 °C (14 °F) applies. For flange material 1.4571/316Ti the lowest temperature range is -20 °C (- 4°F). Nom. diameter Nom. pressure Permissible media DN (inch) Potential equalization Typically, the induced signal voltage of the measuring media can be several μV...

Open the catalog to page 4

Electromagnetic flow Sensor mag-flux A Dimensions (remote version) MECON GmbH Röntgenstraße 105 50169 Kerpen/Germany

Open the catalog to page 5

Electromagnetic flow Sensor mag-flux A __ Ordering data (remote version) Electromagnmetic flow sensor mag-flux A MAG5 7 Li ner PTFE 0 Hard rubber 1 Hard rubber up t o +100 °C 2 Hard rubber f or pot able wat er 3 Sof t rubber 5 N o mi nal p r essur e • PN 10 / JIS 10 K 1 • PN 16 / 150 lbs 2 • PN 25 / 300 lbs 3 • PN 40 4 • special nominal pressure 9 N o mi nal d i amet er • DN 15 / 1/ 2" • DN 25 / 1" • DN 32 / 1 1/ 4" • DN 40 / 1 1/ 2" • DN 50 / 2" • DN 65 / 2 1/ 2" • DN 80 / 3" • DN 100 / 4" • DN 125 / 5" • DN 150 / 6" • DN 200 / 8" • DN 250 / 10" • DN 300 / 12" • DN 350 / 14" • DN 400 / 16"...

Open the catalog to page 6

Electromagnetic flow Sensor mag-flux A __ Dimensions (compact version) MECON GmbH Röntgenstraße 105 50169 Kerpen/Germany

Open the catalog to page 7

Electromagnetic flow Sensor mag-flux A __ Ordering data (compact version) Electromagnmetic flow sensor mag-flux A with mag-flux M1 MAG5 7 Li ner PTFE 0 Hard rubber 1 Hard rubber up t o +100 °C 2 Hard rubber f or pot able wat er 3 Sof t rubber 5 N o mi nal p r essur e • PN 10 / JIS 10 K • PN 16 / 150 lbs • PN 25 / 300 lbs • PN 40 • special nominal pressure N o mi nal d i amet er • DN 15 / 1/ 2" • DN 25 / 1" • DN 32 / 1 1/ 4" • DN 40 / 1 1/ 2" • DN 50 / 2" • DN 65 / 2 1/ 2" • DN 80 / 3" • DN 100 / 4" • DN 125 / 5" • DN 150 / 6" • DN 200 / 8" • DN 250 / 10" • DN 300 / 12" • DN 350 / 14" • DN...

Open the catalog to page 8All MECON catalogs and technical brochures

-

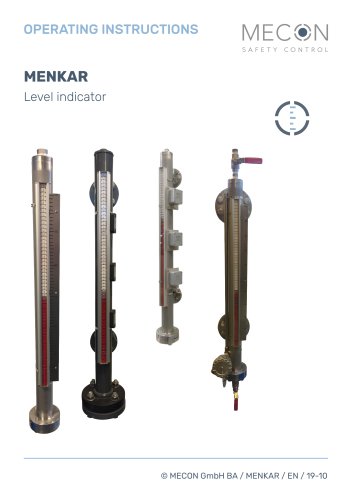

MENKAR KK

28 Pages

-

MENKAR

28 Pages

-

Turbo-Lux® 3

20 Pages

-

N4

20 Pages

-

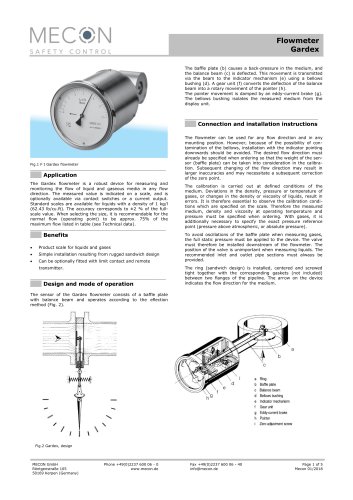

Gardex

5 Pages

-

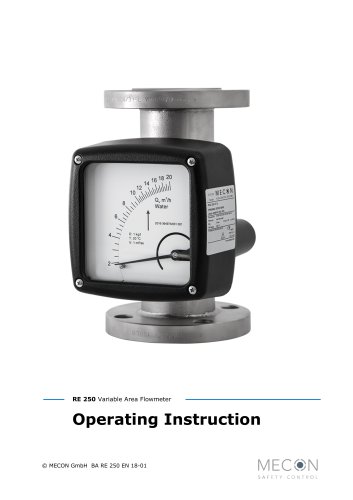

RE 250

32 Pages

-

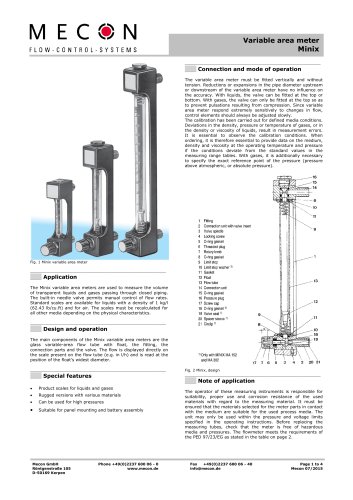

Minix

4 Pages

-

Tubux M30

20 Pages

-

KBF

20 Pages

-

Trogflux

21 Pages

-

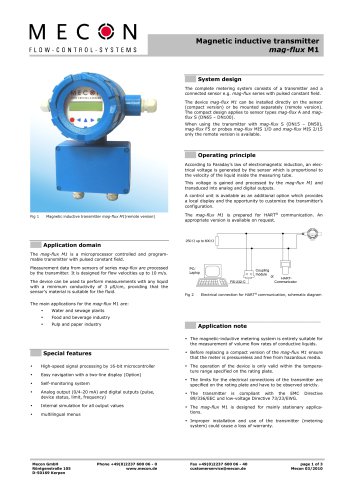

mag-flux M1

35 Pages

-

mag-flux F5

4 Pages

-

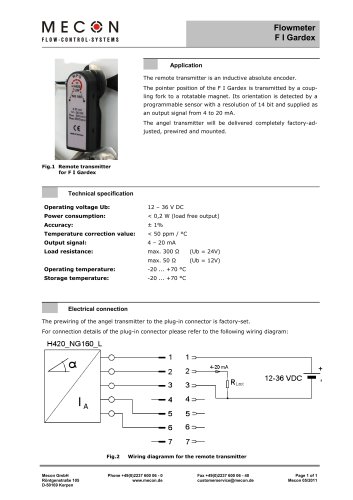

Flowmeter F I Gardex

1 Pages

-

Product catalogue

24 Pages