Website:

MECON

Website:

MECON

Catalog excerpts

Electromagnetic flow Sensor mag-flux F5 __ Special features · Metering tube made from high corrosion- and temperature resistant zirconium oxide Metering tube inner diameter 2 mm (0,078") and above smallest measuring ranges: o 0 to 5 l/h (0 to 0,022 USgpm) with constant field o 0 to 3 l/h (0 to 0,0132 USgpm) with alternating field very low minimum conductivity: o 10 μS/cm with constant field o 0,1 μS/cm with alternating field robust and interference-free as a result of closed steel housing different process connections and materials o Thread: DIN, NPT, BSP o Flange: DIN, ANSI, JIS o Clamp o DIN 11851 o and more upon request different process connection materials o Mat. No. 1.4571 o Hastelloy C4 W. Nr. 2.4610 o PVDF mat. No. 2.4610 Fig. 1 electromagnetic flow sensor mag-flux F5 o and more upon request __ Application Electromagnetic flowmeters are suitable for measuring the flow of almost all electrically conducting liquids, as well as sludges, pastes and slurries. A prerequisite is that the medium must have a certain minimum conductivity. The temperature, pressure, viscosity and density have no influence on the result. This special design of an electromagnetic flowmeter (MID) is particularly suitable for measuring the flow of extremely small quantities and especially for use with proportioning and batching systems. In conjunction with the transmitters Intermag 2/Transmag 2, complex tasks can be solved using the integral software for batching applications. Typical applications can be found in the food industry, the dosing of chemicals in photographic systems, and the dosing of medicines in medical fields. When using the alternating field technique with the transmitter Transmag 2, even very small flows can be exactly measured as a result of the larger magnetic field and the zero stability. The flow sensors mag-flux F5 are used mainly in the following industries: · · · · · · · Water and waste water plants Chemical and pharmaceutical industry Food- and beverage industry Mining, cement and mineral materials Pulp- and paper industry Steel industry Power generation and distribution. · The operator of these measuring instruments is responsible for suitability, proper use and corrosion resistance of the used materials with regard to the measuring material. It must be ensured that the materials selected for the meter parts in contact with the medium are suitable for the used process media. · Before replacing the measuring tubes, check that the meter is free of hazardous media and is not pressurized. · The unit may only be used within the pressure and voltage limits specified on the rating plate. · The flowmeter complies with the requirements of the Pressure Equipment Directive 97/23/EC, article 3, paragraph 3. The most hazardous permissible media are the fluids defined in group 1. · Provide a touch guard for surface temperatures of > 70°C. This touch guard must be designed in a way that the max. allowable ambient temperature on the unit is not exceeded. · The sensor must not be affected by external loads. · The units are designed for predominantly recumbent load. The flow sensor are combined with the transmitters Intermag 2/Transmag 2 and are only available as remote versions. Mecon GmbH Röntgenstraße 105 D-50169 Kerpen

Open the catalog to page 1

Electromagnetic flow Sensor mag-flux F5 __ Installation The measuring principle is generally independent of the flow profile. Ideally, the device should be installed in a pipeline, which has sufficient straight tubing before and after the measuring point. In general, an inlet path of min. 5 x dia. and an outflow zone of min. 2-3 x dia. is required. Fig. 4 Installation in a constantly filled pipe The flow measuring device must be installed so that the measuring pipe cannot run empty and is always filled with medium. The sensor must be installed in a culvert in the case of an unfilled pipe or...

Open the catalog to page 2

Electromagnetic flow Sensor mag-flux F5 __ Dimensions Fig. 2 Electromagnetic flow Sensor mag-flux F5 (without wall mount), dimensions in mm X1 Fig. 3 Electromagnetic flow Sensor mag-flux F5 (with wall mount), dimensions in mm Connection material if flange connection material is PVDF, installation dimension is 160mm! Mecon GmbH Röntgenstraße 105 D-50169 Kerpen

Open the catalog to page 3

Electromagnetic flow Sensor mag-flux F5 __ Technical Data Application field Measuring principle pulsed constant field (DC) Ordering data Electromagnetic flow Sensor mag-flux F5 pulsed alternating field (AC) Inlet Nominal diameter metering tube Measuring range Constant field Alternating field Measuring accuracy Error of measurement Repeat accuracy Operational conditions Mounting position Pressure limits 25 bar/ 362,5 psi higher upon request Pressure/temperature limits with PVDF connections (DIN 8062) Minimum conductivity with constant field · with alternating field Specifications Design...

Open the catalog to page 4All MECON catalogs and technical brochures

-

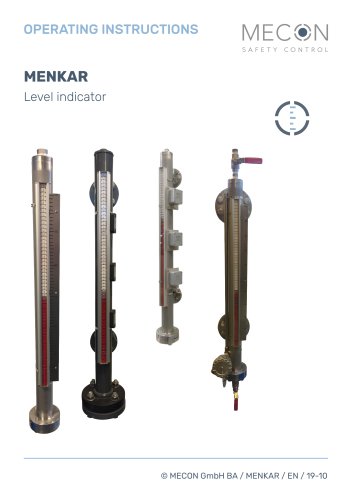

MENKAR KK

28 Pages

-

MENKAR

28 Pages

-

Turbo-Lux® 3

20 Pages

-

N4

20 Pages

-

Gardex

5 Pages

-

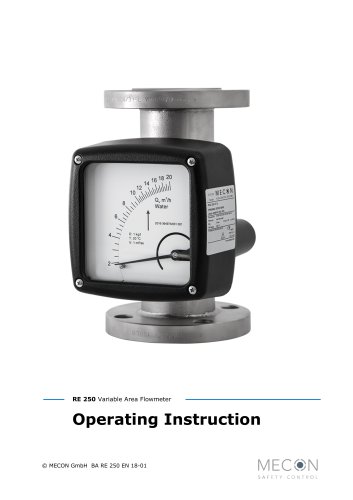

RE 250

32 Pages

-

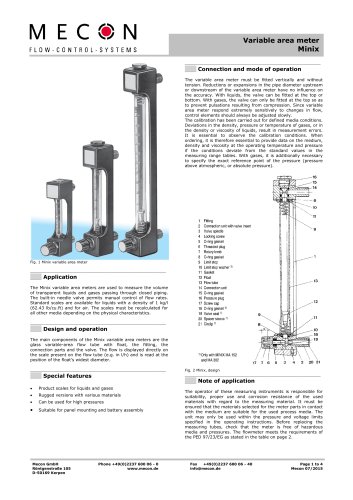

Minix

4 Pages

-

Tubux M30

20 Pages

-

KBF

20 Pages

-

Trogflux

21 Pages

-

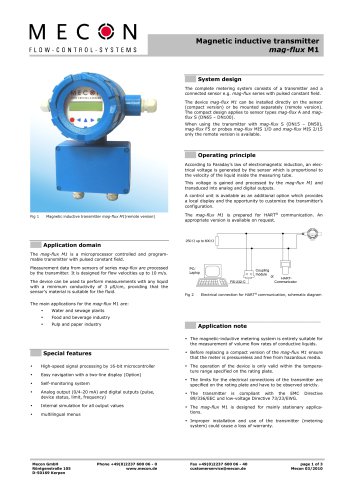

mag-flux M1

35 Pages

-

mag-flux A

9 Pages

-

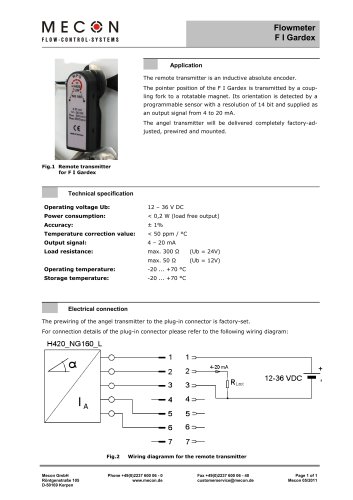

Flowmeter F I Gardex

1 Pages

-

Product catalogue

24 Pages