Website:

MECON

Website:

MECON

Catalog excerpts

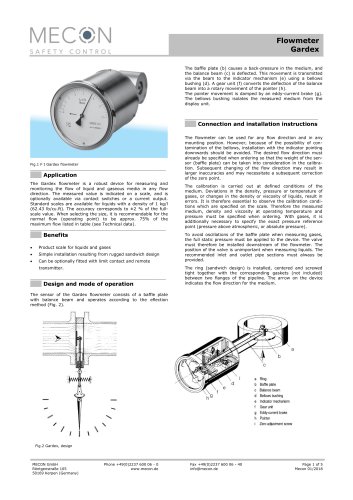

Flowmeter Gardex The baffle plate (b) causes a back-pressure in the medium, and the balance beam (c) is deflected. This movement is transmitted via the beam to the indicator mechanism (e) using a bellows bushing (d). A gear unit (f) converts the deflection of the balance beam into a rotary movement of the pointer (h). The pointer movement is damped by an eddy-current brake (g). The bellows bushing isolates the measured medium from the display unit. ___________________________________________________________ ___ Connection and installation instructions ___ Application The Gardex flowmeter is a robust device for measuring and monitoring the flow of liquid and gaseous media in any flow direction. The measured value is indicated on a scale, and is optionally available via contact switches or a current output. Standard scales are available for liquids with a density of 1 kg/l (62.43 lb/cu.ft). The accuracy corresponds to ±2 % of the fullscale value. When selecting the size, it is recommendable for the normal flow (operating point) to be approx. 75% of the maximum flow listed in table (see Technical data). ____________________________________________________________ Product scale for liquids and gases Simple installation resulting from rugged sandwich design Can be optionally fitted with limit contact and remote transmitter. ___ Design and mode of operation The flowmeter can be used for any flow direction and in any mounting position. However, because of the possibility of contamination of the bellows, installation with the indicator pointing downwards should be avoided. The desired flow direction must already be specified when ordering so that the weight of the sensor (baffle plate) can be taken into consideration in the calibration. Subsequent changing of the flow direction may result in larger inaccuracies and may necessitate a subsequent correction of the zero point. The calibration is carried out at defined conditions of the medium. Deviations in the density, pressure or temperature of gases, or changes in the density or viscosity of liquids, result in errors. It is therefore essential to observe the calibration conditions which are specified on the scale. Therefore the measured medium, density and viscosity at operating temperature and pressure must be specified when ordering. With gases, it is additionally necessary to specify the exact pressure reference point (pressure above atmospheric, or absolute pressure). To avoid oscillations of the baffle plate when measuring gases, the full static pressure must be applied to the device. The valve must therefore be installed downstream of the flowmeter. The position of the valve is unimportant when measuring liquids. The recommended inlet and outlet pipe sections must always be provided. The ring (sandwich design) is installed, centered and screwed tight together with the corresponding gaskets (not included) between two flanges of the pipeline. The arrow on the device indicates the flow direction for the medium. The sensor of the Gardex flowmeter consists of a baffle plate with balance beam and operates according to the eflection method (Fig. 2). MECON GmbH Röntgenstraße 105 50169 Kerpen (Germany)

Open the catalog to page 1

Flowmeter Gardex ____________________________________________________________ ___ Contact assembly ___ Technical data Various contacts/remote transmitters are available: Magnet spring contacts as twin contacts Inductive contacts as single or twin contacts Current output. ___ Maintenance No maintenance work is necessary. ____________________________________________________________ ___ Zero correction A corresponding correction can be made if the pointer zero is offset (e.g. resulting from a changed mounting position). The flowmeter need not be dismounted to do this. Remove the housing...

Open the catalog to page 2

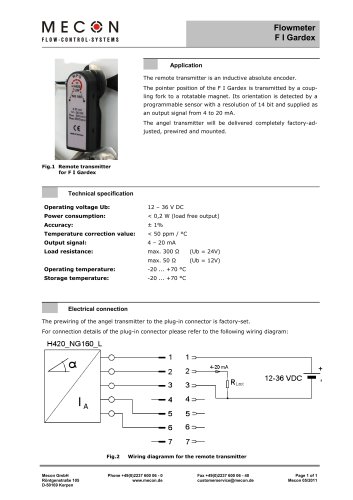

Flowmeter Gardex ____________________________________________________________ ___ Technical specification of contacts ___ Technical specification of angle transmitter Switching principle Magnet spring contact, twin contact Measuring principle Rotation angle transmitter Ambient temperature Power consumption Ambient temperature to comply with EN 50082-2 (EMC), a screened cable must be used which is earthed at one end Max. switching frequency Max. rating 5/min AC 250V / 1A / 50VA DC 250V / 1A / 30W Rating data apply to resistive loads; a suppressor circuit is required for inductive loads...

Open the catalog to page 3

Flowmeter Gardex ____________________________________________________________________________________________________ ___ Measuring ranges, pressure losses and dimensions (liquids and gases) Standard measuring range: liquids (p= 1kg/l (62,43 lb/cu.ft), viscosity 1 mPa.s (1 cp)) (dynamic range 1:5) air (Pe= 0 bar pressure above atmospheric, T= 0°C (32°F), ρ=1,293 kg/m³, v=0,0181 mPa.s) (dynamic range 1:5) Nom. Full-scale value Full-scale value Measuring range Measuring range *) The pressure loss indicates the range from the small up to the large measuring range. ___Measuring ranges, pressure...

Open the catalog to page 4

Flowmeter Gardex ______________________________________________ ___ Selection and Ordering data F I Gardex flowmeter Version (according to Table on page4) • Type 1 Ring: steel Baffle plate: stainless steel • Type 2 Ring: stainless steel 1.4571/316Ti Baffle plate:stainless steel 1.4571/316Ti • Type 3 Ring: steel with rubber liner Baffle plate: stainless steel • Type 4 Ring: steel with rubber liner Baffle plate: Hastelloy • Type 5 Ring: steel with Hastelloy liner Baffle plate: Hastelloy Nominal diameter • DN25 (1" ANSI) • DN40 (1 1/2" ANSI) • DN50 (2" ANSI) • DN65 (2 1/2" ANSI) • DN80 (3"...

Open the catalog to page 5All MECON catalogs and technical brochures

-

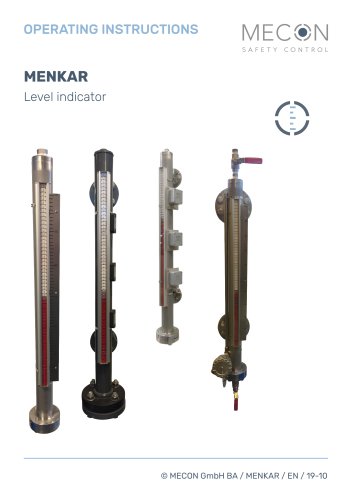

MENKAR KK

28 Pages

-

MENKAR

28 Pages

-

Turbo-Lux® 3

20 Pages

-

N4

20 Pages

-

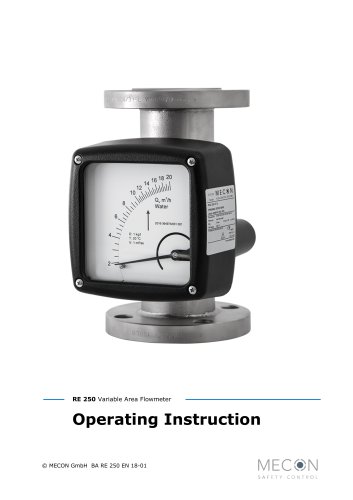

RE 250

32 Pages

-

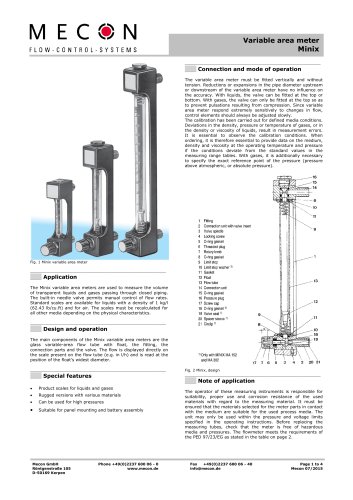

Minix

4 Pages

-

Tubux M30

20 Pages

-

KBF

20 Pages

-

Trogflux

21 Pages

-

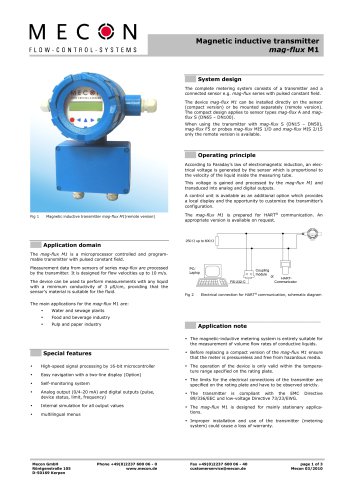

mag-flux M1

35 Pages

-

mag-flux F5

4 Pages

-

mag-flux A

9 Pages

-

Flowmeter F I Gardex

1 Pages

-

Product catalogue

24 Pages