Catalog excerpts

Reflow oven RK360 • Subject to technical alteration • Reflow oven RK 360 • Technical data • Iinfared + Air circulation + Air cooling, Pb-free Reflow Oven • Surface mounting of units on boards require the exposure of the device package to high temperature to melt the lead finish for board soldering. A lot of the alternative "lead-free" solder materials being considered for use in IC assembly today require a peak soldering temperature of about 250 to 260 deg C, versus the peak temperature of 230 to 235 deg C for Sn-Pb solder. This means that lead-free IC's will need a higher temperature for board mounting, and will therefore be subjected to more severe thermo-mechanical stresses during the process. • This Oven feature a complete system for today’s solder/ Pb-Free solder(300C) requirement. The computer control 20 step range (20 Zone) temperature control allow a smooth and well control temperature curve. High power heating element with force air heating method provide a very even soldiering hot zone across the total soldiering area, This cost effective unit offer high production count ( 4~5 mins per cycle of 300mm x 220mm board) which ideal for low to medium size of SMD production. The static soldering process offer very stable non moving especially important for fine pitch SMD soldering. • Features: • Infrared Array + Force Air ( high volume, low pressure ) Heating Method. • Programmable 20 step control for temperature curve setting. • Internal cooling fan for fast Cool down performance. • Fully Automatic, fully static ( non moving rail) operation, single or double side board soldering. • Large transparent glass window see throught the soldering process with high temperature build in 35W light ( separated ON/OFF) switch. • Internal complete high gloss stainless steel construction, high IR efficiency and easy to clean, maintenance. • Ball bearing Rail draw system for stable solider board exchange with minimum vibration. • Optional PCB tray for quick exchange between the board process. • Top Open design for quick access to heating element and service. • Dual channel air circulation. For fast cool down process. • Specifications: • Maximum heating area: 320mm x 220mm • Interchangeable tray for continuous process. • Maximum Temperature: 300C • Power supply: AC220V/50Hz • Maximum Power comsumption: 3.5kW, 1,2kW Typ. • Weight: 50kg • Dimension: 565 x 600 x 500 mm

Open the catalog to page 1All Mechatronic Systems catalogs and technical brochures

-

Reflow oven R260

1 Pages

-

Screen & stencil printer SXL

1 Pages

-

Reflow ovens

1 Pages

-

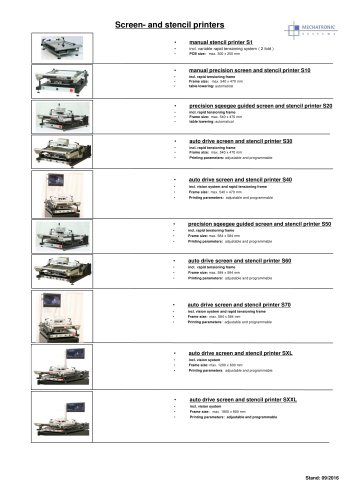

Screen- and stencil printers

1 Pages

-

Screen & stencil printer S90

1 Pages

-

Reflow oven RK320

1 Pages

-

Stencil printer S30

1 Pages

-

P40

1 Pages

-

P30

1 Pages

-

P20

1 Pages

-

S70

1 Pages

-

S60

1 Pages

-

S40

1 Pages

-

S50

1 Pages

-

D10 automatic dispensing system

1 Pages

-

D1 manual dispenser

1 Pages

-

M1 SMD manipulator

1 Pages

-

stencil printers S20

1 Pages

-

stencil printers S10

1 Pages

-

stencil printers S1

1 Pages