Catalog excerpts

Reflow oven R260 Reflow oven R260 • Forced air convection heat to maximum temperatures up to 300°C. • Forced air convection provides uniform heating and prevents shadowing. • Three heat zones, each independently controlled for accurate temperature profiles. • Bench-top unit can be converted to a stand-alone unit by use of the optional cabinet and also integrated into a fully conveyorized production line. • Output to printer, for print-out program data and temperature profiles. • Full colour touch screen for easy programming with user friendly interface. • Viewing panel allows visual inspection of reflow process. • Detachable thermocouple for measuring substrate temperatures. The R 260 convection reflow soldering systems uses re-circulated hot air to accomplish reflow at much lower temperatures than IR systems. Using constant, even heating, a great variety of board sizes will reach reflow temperature with the same heat profile. By eliminating set-up time your production line can work to its fullest capacity. Convection heating provides many other advantages over IR. In addition to the wide process window it works with • No shadowing • No belt load sensivity • No cold solder joints • 3 zone temperature control Technical information: • Power requirements: 208/240VAC 1-phase • Rated power max.: 3650 Watts • 3,8” monochrome touch screen. • Dynamic warming-up control ensuring stable temperatures • and virtually no overshoot. • USB port for direct printing or external storage. • Profiling software for temperature data recording. • Graphic display mode for viewing temperature on a time base. • 2 pre-heat and 1 reflow zone. • Stainless steel spring wires conveyor belt • Conveyor speed: 15 - 60 cm/min(6 - 23 inch/min) • Up to 300°C for lead free soldering. • Clearance for assemblies up to 25mm(1 inch) • Soldering width: 265 mm(10 inch) • Length process chamber: 860 mm(43 inch) • Bottom cooling fans at offload section • Heat-up time: approx. 15 min. • Dimensions: 1540 x 600 x 360 mm(L x W x H) • Net weight: 60 kg

Open the catalog to page 1All Mechatronic Systems catalogs and technical brochures

-

Screen & stencil printer SXL

1 Pages

-

Reflow ovens

1 Pages

-

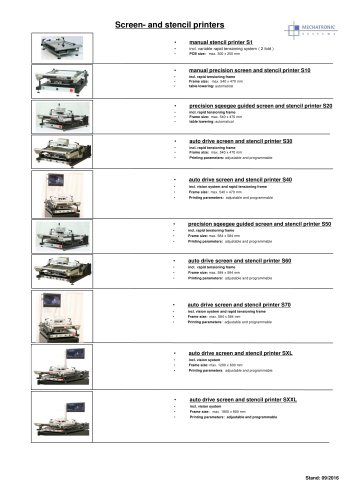

Screen- and stencil printers

1 Pages

-

Screen & stencil printer S90

1 Pages

-

Reflow oven RK320

1 Pages

-

Stencil printer S30

1 Pages

-

P40

1 Pages

-

P30

1 Pages

-

P20

1 Pages

-

S70

1 Pages

-

S60

1 Pages

-

S40

1 Pages

-

S50

1 Pages

-

RK360 reflow oven

1 Pages

-

D10 automatic dispensing system

1 Pages

-

D1 manual dispenser

1 Pages

-

M1 SMD manipulator

1 Pages

-

stencil printers S20

1 Pages

-

stencil printers S10

1 Pages

-

stencil printers S1

1 Pages