Catalog excerpts

SMT pick & place system P40 • TECHNICAL DATA • KEY FEATURES • PCB • full vision SMT pick and place machine max. placement area 400 x 500mm • automatic pick & place head • camerasystem for automatic fiducial • automatic nozzle changer (6 tools ) • camerasystem for components centering Componets centering • CAD – editor for pick & place files non-contact alignment • teach-in mode – electronic manipulator Placement rate • image processing system • intelligent feeder system – CAN Bus • operating system: Windows XP • control panel: PC keybord / Mouse • user interface - PC and 17” LCD monitor • Application range · · low and middle volume production pick & place of standard and fine pitch components incl. BGA , µBGA, CSP, QFN • • • • • • • • • • • • • • • • • • Components range from 0402 up to 30 x 30mm Pitch min. 0,4mm BGA / µBGA Components packing tapes / sticks / trays up to 2000 cph Feeder up to 80 x 8 – automatic tape feeder and 2 x (300 x 200mm) - IC-tray with 200 x 300mm PCB size Resolution X / Y Axis - 0,008mm Placement accuracy +/- 0,03 mm • Dimensions and weight • touchless 840 x 630 x 430 mm / ca. 95 kg • • Supply 230 V - 50 Hz - 350 W / 0,6 Mpa -15 l/min • Subject to technical alteration

Open the catalog to page 1All Mechatronic Systems catalogs and technical brochures

-

Reflow oven R260

1 Pages

-

Screen & stencil printer SXL

1 Pages

-

Reflow ovens

1 Pages

-

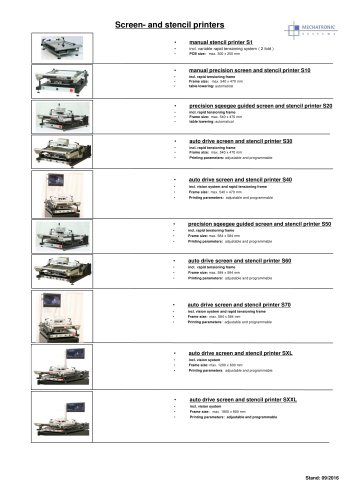

Screen- and stencil printers

1 Pages

-

Screen & stencil printer S90

1 Pages

-

Reflow oven RK320

1 Pages

-

Stencil printer S30

1 Pages

-

P30

1 Pages

-

P20

1 Pages

-

S70

1 Pages

-

S60

1 Pages

-

S40

1 Pages

-

S50

1 Pages

-

RK360 reflow oven

1 Pages

-

D10 automatic dispensing system

1 Pages

-

D1 manual dispenser

1 Pages

-

M1 SMD manipulator

1 Pages

-

stencil printers S20

1 Pages

-

stencil printers S10

1 Pages

-

stencil printers S1

1 Pages