Website:

MECALUX

Website:

MECALUX

Group: Mecalux

Catalog excerpts

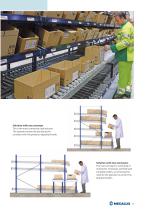

Racking for Live Picking For reduced order picking times and optimal turnover of goods stored

Open the catalog to page 1

This live storage system for light loads reduces order picking times and enables optimal turnover of goods stored. Racking for live picking is made up of slightly inclined platforms of wheels and rollers, on which the goods are deposited at one end. They then slide down on their own until the far end, positioned at the exit aisle. This system guarantees perfect product turnover, prevents interference in the replenishment and collection of material, and increases speed in order preparation. It is designed for areas in the warehouse with a large volume of picking as they increase the number...

Open the catalog to page 2

General Characteristics OPTIMAL TURNOVER • It is achieved due to the FIFO system, where the first box or item to enter is the first one to leave. GREATER NUMBER OF SKUs • In the live picking system, each SKU occupies a space at the front of the rack, the reserve boxes are stored behind this space in the quantity permitted by the depth of the racking. • Having a greater number of SKUs at the front of the rack enables the time spent in the preparation of orders to be considerably reduced, as the routes to collect the different SKUs of each order are much shorter. IMPROVED CAPACITY • Racking...

Open the catalog to page 4

Conventional picking SKUs per bay: 3 Boxes per SKU: 12 No. of SKUs: 120 Total capacity: 1,400 Space used: 100% Live picking SPACE GAINED SKUs per bay: 20 Boxes per SKU: 12 No. of SKUs: 120 Total capacity: 1,400 Space used: 70% The surface area taken up by the load is the same in both cases: compact storage allows the space corresponding to the longitudinal access aisles to be gained, representing a saving of 30% of the surface area of the premises.

Open the catalog to page 5

Construction Systems Medium-depth basic bays Medium-depth bays are the most commonly used. They are built using adjustable platforms made up of side panels, entry profiles, exit beams, cross-ties, mini-rails and securing components. The platforms can be standard bed frames (without inclined bed frames) or fitted with display trays. The incline of the latter can be adjusted to make it easier to extract the products stored inside the boxes. There is also the possibility of modifying the height and the slope in gauges of 25 mm. In addition, the part protruding from the support points can be...

Open the catalog to page 6

Basic components 1 . Frames and uprights 2. Beams 3 . Complete bed frames: standard 4 . Complete bed frames with display tray 5 . PD3 bed frame supports 6 . Safety pins 7 . Anchor bolts 8 . Levelling plates (shims) 9 . Mini-rails 10 . PKD mini-rail clips Optional components 11. Mini-rail brakes 12. PD3 separators 13. PD3 guide profiles

Open the catalog to page 7

Construction Systems It is possible to easily rearrange the initial layout in terms of rails and inclination in order to adapt them to the changes to the warehouse. Thus: . Each type of box needs a given type of layout and inclination both due to the characteristics of the material with which it is manufactured as well as its sizes and weight. . Cardboard boxes are sensitive to damp and humidity in the warehouse, and a different layout or inclination is required. . A warehouse of these characteristics is a living warehouse, with frequent changes of product, either due to ABC criteria,...

Open the catalog to page 8

Construction Systems Basic shallow depth bay This is the simplest system. It is made up of vertical frames, PD entry and exit beams and rails with wheels. It is used for light loads in shallow depth racks. The beams have adjustment slots to fit the fixing clips. Basic components 1. Frames 2. PD entry beams 3. PD exit beams 4. Mini-rails with wheels 5. Rail fixing clips 6. Safety pins 7. Anchor bolts 8. Levelling plates (shims) Optional components 9. Separators 10. Guides 11. Brakes 10 Racking for Live Picking

Open the catalog to page 10

Bay with pallet reserve Usually, pallets with reserve goods are stored in the upper part of the live racking. The construction method is shown in the following image: 18 12. Pallet racking frames 13. 80MLD uprights with ties 14. 2C pallet racking beams 15. MS beams 16. Complete bed frames with mini-rails and accessories 17. PD3 adapters 18. End-stops and protection mesh 19. Anchor bolts 20. Levelling plates (shims) 21. Connecting components 22. PD3 frame supports

Open the catalog to page 11

Construction Systems Bay with bench for conveyor The bench fitted with rollers or a conveyor belt is installed to facilitate order preparation, allowing prepared products and complete boxes to slide along. 23. Uprights with footplate 24. PD conveyor support 25. Conveyor 12 Racking for Live Picking

Open the catalog to page 12

Solution with one conveyor This is the most commonly used solution. The operator moves the box along the conveyor with the products deposited inside. Solution with two conveyors The inner conveyor is continually in movement. The boxes are filled with complete orders, so removing the need for the operator to extract the prepared orders.

Open the catalog to page 13

Construction Systems Mobile bays Using the same components as a basic bay (both for bays built with frames and those built with beams), mobile bays can be formed by fitting a platform with wheels inside the bay, as is shown in this illustration . Systems with great depth In installations with a great depth of racking, the frames are spliced together using frame side profiles. Bed frame ties are used to connect the pieces. The rest of components are the same. 14 Racking for Live Picking Mini-rail splice

Open the catalog to page 14

Construction Systems The bed frames or platforms hold the stored goods. They are designed to join the different components necessary and can be fully adjusted. Assembly and the modification of the positions of their adjustable components are both very simple. There are two types of bed frames: - Standard bed frames. - Bed frames with a display tray. 1 2 Standard bed frames Basic components 1. PD3 bed frame side profiles 2. PD3 entry profiles 3. PD3 exit profiles 4. PD3 cross-ties 5. PD3 bed frame ties 6. Bed frame side profile plugs 7. PD3 bed frame safety bolts 16 Racking for Live Picking

Open the catalog to page 16All MECALUX catalogs and technical brochures

-

Conveyor systems for boxes

48 Pages

-

Pallet conveyor systems

64 Pages

-

Automated warehouses

120 Pages

-

Wire mesh partitions & cages

8 Pages

-

Mezzanines

20 Pages

-

Cantilever Racking

24 Pages

-

Metal Point Boltless Shelving

24 Pages

-

M3 Shelving for picking

36 Pages

-

M7 Longspan shelving

31 Pages

-

Push-back pallet racking

12 Pages

-

Live Pallet Racking

28 Pages

-

Pallet Shuttle

36 Pages

-

Movirack Mobile Pallet Racking

20 Pages

-

Drive-in Pallet Racking

32 Pages

-

Conventional Pallet Racking

44 Pages