Catalog excerpts

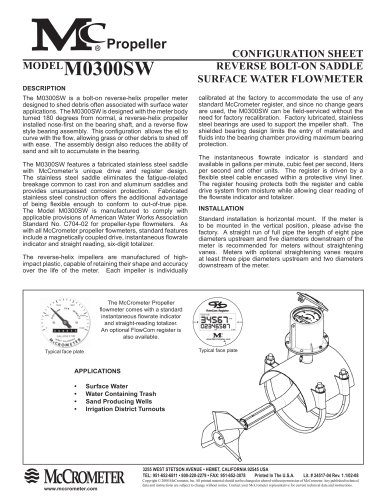

INSTALLATION Standard installation is horizontal mount. If the meter is to be mounted in the vertical position, please advise the factory. A straight run of full pipe the length of eight pipe diameters upstream and ve diameters downstream of the meter is recommended for meters without straightening vanes. Meters with optional straightening vanes require at least three pipe diameters upstream and two diameters downstream of the meter. > DESCRIPTION The M0300SW is a bolt-on reverse-helix propeller meter designed to shed debris often associated with surface water applications. The M0300SW is designed with the meter body turned 180 degrees from normal, a reverse-helix propeller installed nose- rst on the bearing shaft, and a reverse ow style bearing assembly. This con guration allows the ell to curve with the ow, allowing grass or other debris to shed off with ease. The assembly design also reduces the ability of sand and silt to accumulate in the bearing.The M0300SW features a fabricated stainless steel saddle with McCrometers unique drive and register design. The stainless steel saddle eliminates the fatigue-related breakage common to cast iron and aluminum saddles and provides unsurpassed corrosion protection. Fabricated stainless steel construction offers the additional advantage of being exible enough to conform to out-of-true pipe. The Model M0300SW is manufactured to comply with applicable provisions of American Water Works Association Standard No. C704-02 for propeller-type owmeters. As with all McCrometer propeller owmeters, standard features include a magnetically coupled drive, instantaneous owrate indicator and straight reading, six-digit totalizer.The reverse-helix impellers are manufactured of high-impact plastic, capable of retaining their shape and accuracy over the life of the meter. Each impeller is individually calibrated at the factory to accommodate the use of any standard McCrometer register, and since no change gears are used, the M0300SW can be eld-serviced without the need for factory recalibration. Factory lubricated, stainless steel bearings are used to support the impeller shaft. The shielded bearing design limits the entry of materials and uids into the bearing chamber providing maximum bearing protection.The instantaneous owrate indicator is standard and available in gallons per minute, cubic feet per second, liters per second and other units. The register is driven by a exible steel cable encased within a protective vinyl liner. The register housing protects both the register and cable drive system from moisture while allowing clear reading of the owrate indicator and totalizer. > The McCrometer Propeller owmeter comes with a standard instantaneous owrate indicator and straight-reading totalizer.An optional FlowCom register is also available. Typical face plateTypical face plate APPLICATIONSSurface WaterWater Containing Trash Sand Producing Wells Irrigation District Turnoutsҕ Օ > 3255 WEST STETSON AVENUE Օ HEMET, CALIFORNIA 92545 USATEL: 951-652-6811 800-220-2279 Օ FAX: 951-652-3078 Printed In The U.S.A. Lit. # 24517-04 Rev. 1.1/02-08 Copyright 2008 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative for current technical data and instructions. www.mccrometer.com size="-2">

Open the catalog to page 1All McCrometer catalogs and technical brochures

-

FPI Mag

4 Pages

-

Scotchkot

4 Pages

-

CN02 Register Extension

2 Pages

-

Irrigation Rain Gauge

1 Pages

-

Solar Radiation Sensor

1 Pages

-

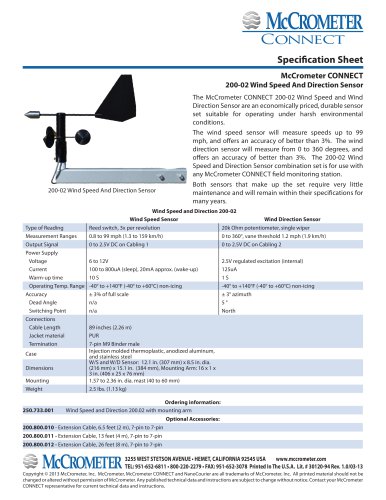

Wind Speed And Direction

2 Pages

-

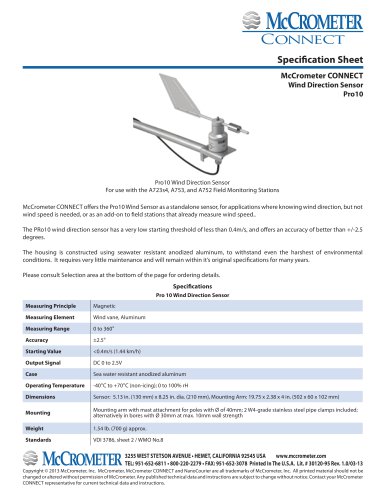

Wind Direction Sensor

1 Pages

-

Level Sensor

2 Pages

-

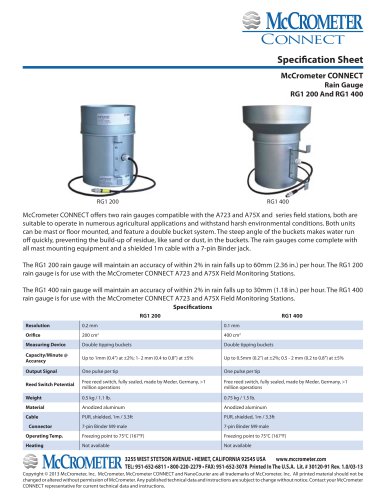

Rain Gauge_200 and 400

1 Pages

-

WHITE PAPER

5 Pages

-

Ultra Mag

4 Pages

-

Wafer-Cone

4 Pages

-

V2

4 Pages

-

V-Cone

6 Pages

Archived catalogs

-

Product Catalogue

40 Pages