Catalog excerpts

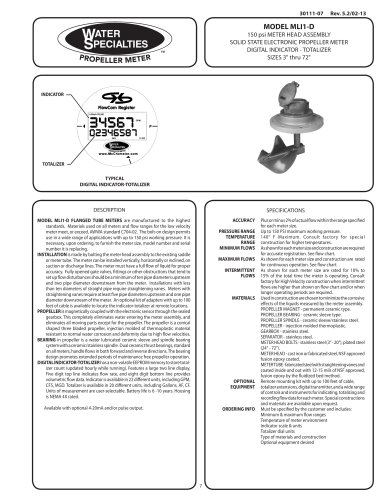

150 psi METER HEAD ASSEMBLY SOLID STATE ELECTRONIC PROPELLER METER DIGITAL INDICATOR - TOTALIZER SIZES 3" thru 72" TOTALIZER TYPICAL DIGITAL INDICATOR-TOTALIZER SPECIFICATIONS ACCURACY MODEL MLI1-D FLANGED TUBE METERS are manufactured to the highest standards. Materials used on all meters and flow ranges for the low velocity meter meet, or exceed, AWWA standard C704-02. The bolt-on design permits use in a wide range of applications with up to 150 psi working pressure. It is necessary, upon ordering, to furnish the meter size, model number and serial number it is replacing. INSTALLATION is made by bolting the meter head assembly to the existing saddle or meter tube. The meter can be installed vertically, horizontally or inclined, on suction or discharge lines. The meter must have a full flow of liquid for proper accuracy. Fully opened gate valves, fittings or other obstructions that tend to set up flow disturbances should be a minimum of ten pipe diameters upstream and two pipe diameter downstream from the meter. Installations with less than ten diameters of straight pipe require straightening vanes. Meters with straightening vanes require at least five pipe diameters upstream and one pipe diameter downstream of the meter. An optional kit of adapters with up to 100 feet of cable is available to locate the indicator-totalizer at remote locations. PROPELLER is magnetically coupled with the electronic sensor through the sealed gearbox. This completely eliminates water entering the meter assembly, and eliminates all moving parts except for the propeller. The propeller is a conical shaped three bladed propeller, injection molded of thermoplastic material resistant to normal water corrosion and deformity due to high flow velocities. BEARING in propeller is a water lubricated ceramic sleeve and spindle bearing system with a ceramic/stainless spindle. Dual ceramic thrust bearings, standard on all meters, handle flows in both forward and reverse directions. The bearing design promotes extended periods of maintenance free propeller operation. DIGITAL INDICATOR-TOTALIZER has a non-volatile EEPROM memory to store totalizer count (updated hourly while running). Features a large two line display. Five digit top line indicates flow rate, and eight digit bottom line provides volumetric flow data. Indicator is available in 22 different units, including GPM, CFS, MGD. Totalizer is available in 20 different units, including Gallons, AF, CF. Units of measurement are user-selectable. Battery life is 6 -10 years. Housing is NEMA 4X rated. PRESSURE RANGE TEMPERATURE RANGE MINIMUM FLOWS MAXIMUM FLOWS INTERMITTENT FLOWS OPTIONAL EQUIPMENT Available with optional 4-20mA and/or pulse output. ORDERING INFO Plus or minus 2% of actual flow within the range specified for each meter size. Up to 150 PSI maximum working pressure. 140° F Maximum. Consult factory for special construction for higher temperatures. As shown for each meter size and construction are required for accurate registration. See flow chart. As shown for each meter size and construction are rated for continuous operation. See flow chart. As shown for each meter size are rated for 10% to 15% of the total time the meter is operating. Consult factory for High Velocity construction when intermittent flows are higher than shown on flow chart and/or when longer operating periods are required. Used in construction are chosen to minimize the corrosive effects of the liquids measured by the meter assembly. PROPELLER MAGNET - permanent ceramic type. PROPELLER BEARING - ceramic sleeve type. PROPELLER SPINDLE - ceramic sleeve/stainless steel. PROPELLER - injection molded thermoplastic. GEARBOX - stainless steel. SEPARATOR - stainless steel. METER HEAD BOLTS - stainless steel (3" - 20"), plated steel (24" - 72"). METER HEAD - cast iron or fabricated steel, NSF approved fusion epoxy coated. METERTUBE - fabricated steel with straightening vanes and coated inside and out with 12-15 mils of NSF approved, fusion epoxy by the fluidized bed method. Remote mounting kit with up to 100 feet of cable, totalizer extensions, digital transmitter, and a wide range of controls and instruments for indicating, totalizing and recording flow data for each meter. Special constructions and materials are available upon request. Must be specified by the customer and includes: Minimum & maximum flow ranges Temperature of meter environment Indicator scale & units Totalizer dial units Type of materials and construction Optional equipment desired

Open the catalog to page 1

150 psi METER HEAD ASSEMBLY SOLID STATE ELECTRONIC PROPELLER METER DIGITAL INDICATOR-TOTALIZER SIZES 3" thru 72" F - Number of Bolts G - Size of Bolts ** PLEASE SPECIFY PIPE I.D. AND O.D. STANDARD HIGH VELOCITY & PIPE CONSTRUCTION CONSTRUCTION SIZE MIN. - MAX. - INT. MIN. - MAX. A EST SHIPPING WEIGHT POUNDS Standard construction will be supplied for all main line meters unless special flow range, materials, or construction are required. 3255 WEST STETSON AVENUE • HEMET, CALIFORNIA 92545 USA TEL: 951-652-6811 • FAX: 951-652-3078 www.mccrometer.com Copyright © 2003-2013 McCrometer. All...

Open the catalog to page 2All McCrometer catalogs and technical brochures

-

FPI Mag

4 Pages

-

Scotchkot

4 Pages

-

CN02 Register Extension

2 Pages

-

Irrigation Rain Gauge

1 Pages

-

Solar Radiation Sensor

1 Pages

-

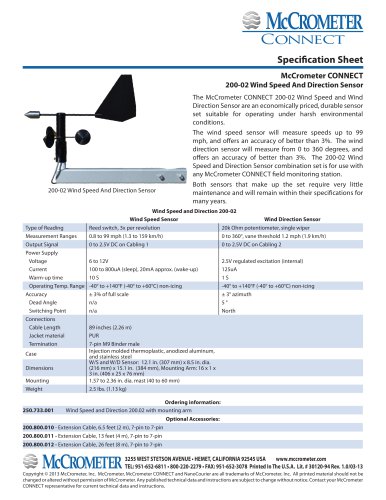

Wind Speed And Direction

2 Pages

-

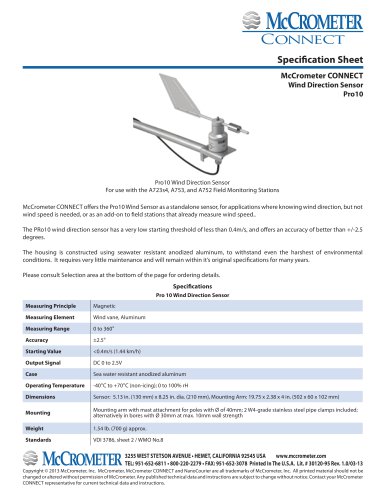

Wind Direction Sensor

1 Pages

-

Level Sensor

2 Pages

-

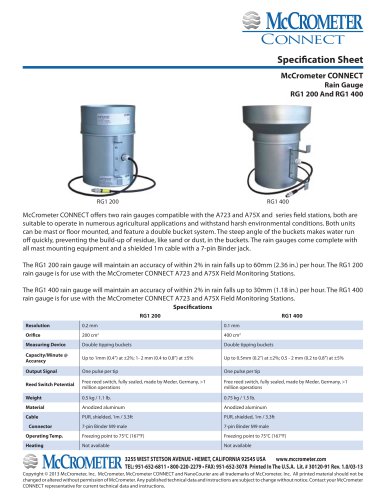

Rain Gauge_200 and 400

1 Pages

-

WHITE PAPER

5 Pages

-

Ultra Mag

4 Pages

-

Wafer-Cone

4 Pages

-

V2

4 Pages

-

V-Cone

6 Pages

Archived catalogs

-

Product Catalogue

40 Pages